Competition in the thermal paste market is fierce, and high-end and environmental protection are its important upgrade directions.

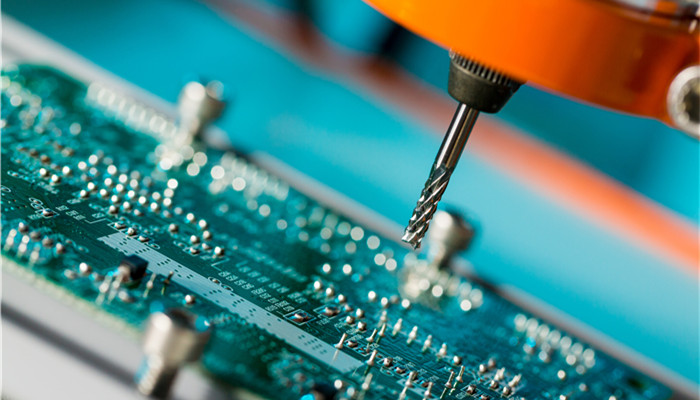

Thermal paste, also known as thermal paste, is a gray or white paste-like substance with good thermal conductivity. Thermal paste has the characteristics of resistance to high and low temperature changes, thermal and non-conductive properties, weather aging resistance, and stable chemical and physical properties. It is mainly used in radiators (such as heat sinks, heat strips, shells, etc.) and heat sources (such as power tubes, electric heaters) (pile, etc.) surface, used to fill gaps and increase the contact area, thereby achieving the best heat conduction and heat dissipation effects.

Thermal paste is widely used in consumer electronics, power devices, ships, communication equipment, 5G base stations, new energy vehicles, industry and other fields. In the field of electronic manufacturing, although the amount of thermal paste is not large, it plays an irreplaceable role, such as improving the stability and reliability of electronic devices. In recent years, thanks to the rapid development of the downstream market, the demand for thermal paste applications has continued to increase, and the market size has also expanded.

According to the “2023-2027 China Thermal Paste Industry Market Monitoring and Future Development Prospects Research Report released by the Industrial Research Center, In 2021, the global thermal paste market will be approximately US$140 million, with China accounting for the largest market share, accounting for more than one-third, followed by the North American market. It is expected that from 2023 to 2027, with the development of downstream industries and technological progress, the thermal paste market will maintain a growth trend, with an average annual compound growth rate of more than 6.0%.

According to different ingredients, thermal paste can be divided into two categories: silicon-containing thermal paste and silicon-free thermal paste. Among them, silicon-containing thermal paste is the mainstream product in the market, accounting for about 90%. Due to the rapid development of new technologies and the rapid update of heat dissipation materials, the homogeneity of thermal paste products is serious and the quality is uneven, which is not conducive to the long-term development of the industry. In the future, relevant companies still need to increase technology and R&D investment to improve the performance of thermal paste. , to promote the development of products in the direction of environmental protection, high efficiency and low volatility.

There are many thermal paste manufacturers and the market competition is fierce. In the international market, the main suppliers of thermal paste include DuPont, Dow, Panasonic, Shin-Etsu, Fuji, 3M, etc. Foreign companies have obvious advantages in technology, brand, category, performance, etc. Competitive Advantage. my country’s thermal paste market research and application started late. Due to insufficient core technologies, the competitive advantages of domestic enterprises are mostly reflected in large quantities and excellent prices. At present, my country’s thermal paste manufacturers include Huitian New Materials, Sinopec Technology, Optical Titanium Technology, Feirongda, etc.

Industry analysts said that thermal paste plays the role of a heat transfer medium and can improve the heat dissipation of electronic products, electrical equipment, and communication equipment. Effect. There are many thermal paste manufacturers and the market competition is fierce. Foreign companies have technological advantages and occupy a major share of the high-end market. my country is a major producer and consumer of thermal paste, but the quality of domestic thermal paste is uneven. Under the background of escalating demand and stricter environmental protection , the thermal paste industry needs to be upgraded to a high-end direction.

微信扫一扫打赏

微信扫一扫打赏