my country’s polishing pad market is in short supply and there is huge room for market improvement in the future

Polishing pad, also known as polishing cloth, is one of the mainstream polishing materials and has the characteristics of elasticity, looseness and porousness. There are many types of polishing pads. According to different groove structures, polishing pads can be divided into microporous polymers, hollow films, non-porous polymers, etc.; according to different materials, polishing pads can be divided into synthetic leather polishing pads and polyurethane polishing pads. Pads, gold velvet polishing pads, etc. Among them, polyurethane polishing pads have outstanding advantages and are the most common type of polishing pads.

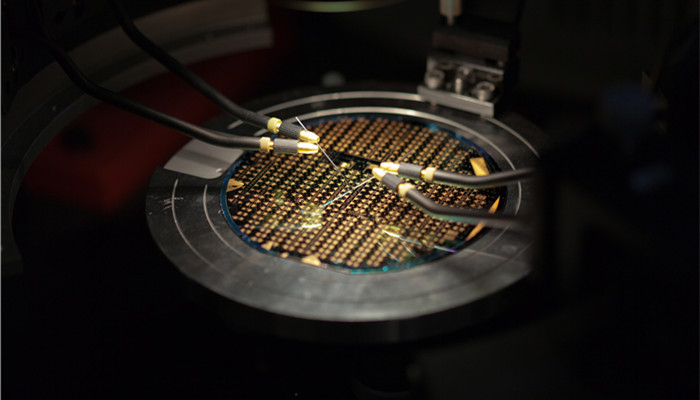

From the perspective of the industry chain, the upstream of the polishing pad industry chain is the supply layer of raw materials and processing equipment, involving non-woven fabrics, polyurethane, synthetic leather and other raw materials; the middle reaches of the industry chain is the production layer, involving preparation such as glue application, groove engraving, and slicing. process; the downstream of the industrial chain is the application layer, in which wafer processing is the main application scenario of polishing pads. In recent years, thanks to the development of the global wafer processing industry, the market demand for polishing pads has continued to grow, and the scale of the industry has continued to expand.

According to the “2022-2026 Polishing Pad Industry Market In-depth Research and Investment Prospects Forecast Analysis Report released by the Industrial Research Center, in 2019 -In 2021, the global polishing pad market will show a steady growth trend. By 2021, the market size will have reached approximately US$880 million. my country is a major wafer processing country, and the polishing pad market is growing rapidly, reaching 1.34 billion yuan in 2021. It is expected that in the future, my country will occupy an increasingly important position in the global polishing pad market.

Benefiting from the development of industries such as semiconductors and artificial intelligence, the demand for polishing pads continues to grow. However, due to insufficient domestic production capacity, my country’s polishing pad market is still in short supply. In 2021, the polishing pad supply gap will reach about 600,000 pieces. In China, the main polishing pad manufacturers include Huahong Electronics, Dinglong Co., Ltd., SMIC, Betta Advanced Materials, etc. Among them, Dinglong Co., Ltd. is the leading company in my country’s polishing pad industry.

In the international market, polishing pad suppliers include Dow Chemical, Toyo Rubber, Applied Materials, JSR, Toray Industries, etc. The global polishing pad market is highly concentrated, with American, Japanese and Korean companies dominating the market. Among them, Dow Chemical of the United States accounts for more than 75.5% of the polishing pad market, which is an absolute leader.

With the upgrading of preparation technology, the development trend of wafer miniaturization has emerged, and the production capacity of 8-inch and 12-inch wafers has continued to rise. Against this background, the market’s requirements for the processing quality, processing efficiency, and stability of polishing pads have also continued to increase. High-end Optimization, efficiency and refinement have gradually become important upgrade directions for polishing pads.

Industry analysts said that my country’s polishing pad industry started late, but thanks to the development of the domestic wafer processing industry, the polishing pad market Development is rapid, and industry output continues to grow. Due to technical limitations, the polishing pad market is highly concentrated, and the global market is still dominated by American, Japanese and Korean companies. In contrast, the competitive advantages of Chinese polishing pad companies are generally insufficient, and there is broad space for companies to improve in the future.

微信扫一扫打赏

微信扫一扫打赏