Ceramic membranes have a wide range of applications and huge potential for industry development

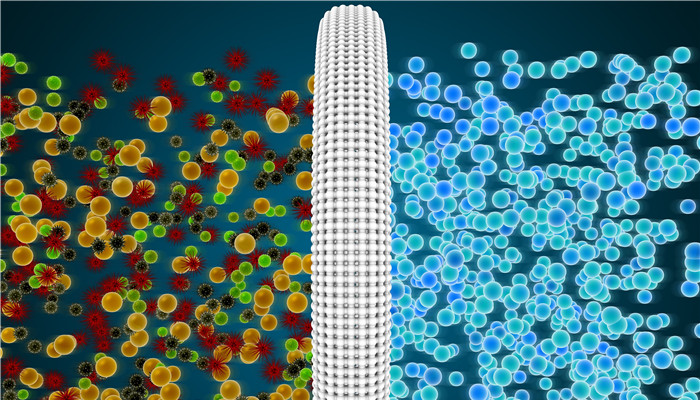

Ceramic membrane, also known as inorganic ceramic membrane, is an asymmetric membrane made of inorganic ceramic materials. Compared with traditional polymer separation membranes, ceramic membranes have the advantages of high separation efficiency, high temperature resistance, high mechanical strength, and good chemical stability. They are widely used in petrochemical industry, food processing, medicine, biological fermentation and other fields. According to different supports, ceramic membranes can be divided into three types: tubular ceramic membranes, flat ceramic membranes, and multi-channel ceramic membranes.

The development of the ceramic membrane industry started in the 1940s, and was initially mainly used in the separation and enrichment technology of uranium isotopes in the nuclear industry. In the 1980s, the United States, Germany, Japan, France and other countries began to apply ceramic membrane technology to civilian products, and the ceramic membrane industry began to achieve commercial development. With the continuous innovation of technology, the market demand for ceramic membranes is becoming increasingly strong. The global ceramic membrane market size will reach US$5.61 billion in 2021, a year-on-year increase of 14.6%. In terms of the local market, my country’s ceramic membrane industry started late but is developing rapidly. According to the “2022-2027 Ceramic Membrane Industry In-depth Market Research and Investment Strategy Suggestions Report released by the Industrial Research Center, in 2021 The size of my country’s ceramic membrane market reached US$880 million, a year-on-year increase of 31.5%.

Ceramic membranes are widely used in a wide range of applications, with the pharmaceutical field being the largest demand end, accounting for 30.0% of the demand. Ceramic membranes have extremely strong antibacterial properties and can fully meet the sterility requirements of pharmaceutical production. Currently, ceramic membrane separation and purification technology has been widely used in the biopharmaceutical production process of major pharmaceutical companies, including antibiotics such as erythromycin and cephalosporins. All are produced using this technology. Ceramic membranes also have good chemical stability and are suitable for long-term and stable separation operations in harsh environments. In recent years, there has been an increasing demand for ceramic membrane applications in the field of wastewater treatment, including petrochemical wastewater, domestic sewage, and oily wastewater treatment.

Sanda Membrane, Kelang Membrane Technology, Netyuan Membrane Technology, Jiuwu Hi-Tech, Shijie Membrane Engineering, Aotai Membrane Technology, etc. are the main suppliers of ceramic membranes in my country. In recent years, driven by positive factors such as national policy support and technological innovation by local companies, the localization process of my country’s ceramic membranes has been accelerating.

Silicon carbide ceramic membrane is the mainstream product in my country’s ceramic membrane market. It uses silicon carbide as raw material and can continuously remove magnetic particles and suspended solids. It is a high-end ceramic membrane. The global silicon carbide ceramic membrane market size will reach US$60 million in 2021, a year-on-year growth of 5.7%.

Industry analysts said that as an emerging material, ceramic membranes have excellent performance and are widely used in many fields. As market demand is gradually released, The future development prospects of the industry will continue to improve. my country’s ceramic membrane industry started late, and overseas brands have long dominated the Chinese market. In recent years, with the continuous breakthroughs in production technology of leading companies, the quality of my country’s ceramic membrane products has continued to improve, and the localization process of the industry has continued to accelerate.

微信扫一扫打赏

微信扫一扫打赏