Carbon-based composite materials have excellent performance and market demand continues to rise

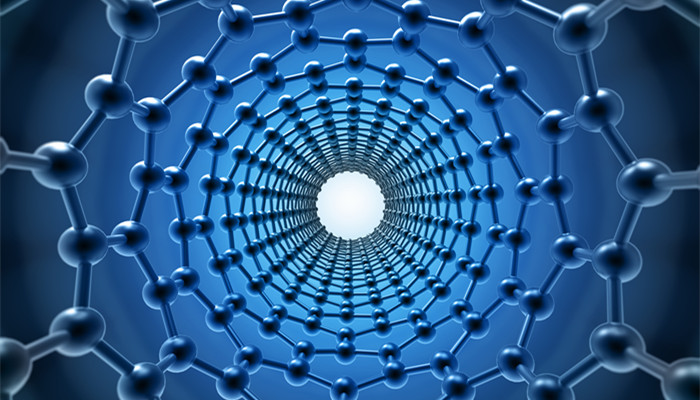

Carbon-based composite materials refer to composite materials that use carbon fiber or ceramic fibers such as silicon carbide as reinforcement and carbon as the matrix. Carbon-based composite material preparation processes include impregnation and chemical vapor deposition (CVD).

The main raw material of carbon-based composite materials is carbon fiber. Carbon fiber is usually made of acrylic fiber and viscose fiber as raw materials and is prepared through high-temperature carbonization. Its carbon content reaches more than 90.0%. In recent years, driven by market demand, my country’s carbon fiber production capacity has rapidly expanded and output has continued to increase. In 2021, my country’s carbon fiber output will reach 24,000 tons, a year-on-year increase of 32.6%. Benefiting from the sufficient supply of raw materials, my country’s carbon-based composite material output has shown a steady growth trend. According to the “2022-2027 China Carbon Matrix Composite Materials Project Investment Feasibility Research Report released by the Industrial Research Center, in 2021 my country’s carbon-based composite material output reached 512,000 tons, a year-on-year increase of 7.9%.

The application fields of carbon-based composite materials include petrochemical industry, aerospace, photovoltaic power generation, semiconductor and automobile manufacturing. The photovoltaic power generation and semiconductor fields are the largest demand ends for carbon-based composite materials. In the field of photovoltaic power generation, carbon-based composite materials can be used as the main raw materials for wafer carriers, electrodes, fasteners, guide tubes and other components; in the semiconductor field, carbon-based composite materials are mainly used to manufacture semiconductor silicon wafers. With the rapid development of national strategic emerging industries such as photovoltaic power generation and semiconductors, the market size of carbon-based composite materials will continue to expand.

According to different matrix, carbon-based composite materials can be divided into two categories: carbon/ceramic composite materials and carbon/carbon composite materials. Carbon/ceramic composite materials have the advantages of high modulus, high hardness, light weight, and impact resistance, and are widely used in the aerospace field. Carbon/carbon composite materials are one of the ideal materials for manufacturing friction parts and high-temperature thermal field components. Driven by technological innovation, application fields such as rocket engines and aircraft brake discs are increasingly dependent on the ultra-high temperature performance of carbon/carbon composite materials.

There are many carbon-based composite material manufacturers in my country, and leading companies occupy a dominant position in the market. Jinbo Co., Ltd., TBEA, Xi’an Super Code, Guangwei Composite Materials, Kingfa Technology, etc. are the main suppliers of carbon-based composite materials in my country. In recent years, Jinbo has focused on technological innovation and industrial application of carbon-based composite materials, and its products are widely used in new energy vehicles, aerospace and other fields. According to the annual report of Jinbo Co., Ltd., the company achieved operating income of 1.34 billion yuan in 2021, a year-on-year increase of 213.0%.

Industry analysts said that carbon-based composite materials have the advantages of low density, good mechanical properties, corrosion resistance, etc., and are widely used in many high-tech fields. obtain widespread application. With the rapid economic development and continuous technological innovation, the market demand for carbon-based composite materials will further grow, and the development prospects of the industry will continue to improve. There are many carbon-based composite materials manufacturers in my country and the market competition is fierce. Driven by leading companies, the concentration of my country’s carbon-based composite materials industry continues to increase.

微信扫一扫打赏

微信扫一扫打赏