Barium titanate has broad prospects and the rise of domestic brands

Barium titanate, also known as barium metatitanate, has a molecular formula of BaTiO3 and a molecular weight of 233.19. It has a typical perovskite structure and is insoluble in hydrochloric acid and concentrated sulfuric acid, as well as hydrofluoric acid, dilute nitric acid, water and alkaline solutions.

In terms of specific products, barium titanate can be divided into multiple product types based on particle size, crystal form, use, etc. Taking the particle size index as an example, the particle size products of mid-to-low-end products include 400nm, 500nm, etc., and the particle size of high-end products can be Reaching 50nm, even 30nm, 20nm. Barium titanate products have the characteristics of “customization”, which is reflected in the fact that customers will purchase corresponding varieties of barium titanate products according to the types of MLCC they produce, and propose relatively unique technical parameters and specifications for barium titanate products based on the specific requirements of their MLCC products. Quality requirements.

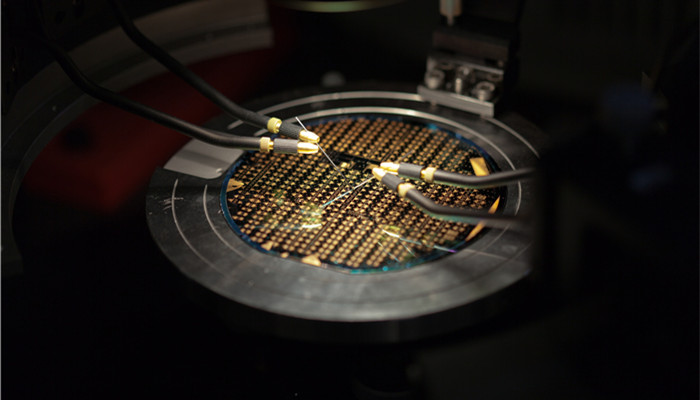

Barium titanate is a chemical product. It is mainly used in the production and manufacturing of MLCC, single-plate ceramic capacitors, thermistors, piezoelectric ceramics, microwave ceramics and other electronic components. Especially in the production of MLCC, its application scale is relatively large, and The above-mentioned electronic devices are ultimately used in mobile phones, computers, color TVs, automobiles, military industry and other fields. In recent years, domestic MLCC companies have continued to increase investment in technology, gradually shortening the gap with overseas leaders such as Murata, Taiyo Yuden, and TDK. The localization rate of MLCC has continued to increase, driving the growth in demand for barium titanate materials. According to the 《2022-2026 titanium The barium acid industry in-depth market research and investment strategy recommendation report》 shows that in 2021, China’s titanium acid The demand for barium reaches about 25,000 tons.

According to the different strengths of the companies, domestic and foreign barium titanate companies can be divided into three camps: The first camp is multinational companies such as Murata and Sakai Chemical Company. Their barium titanate production technology is advanced and their products are concentrated in the mid-to-high-end field. They are for self-use or Mainly supplying multinational MLCC companies; the second camp is China Ceramics Materials. The company is the second company in the world to use the hydrothermal method to produce barium titanate, and the product quality is higher than other domestic manufacturers; the third camp includes Hubei Tiantian Ceramics , Songyuan Electronics, Besco, etc., are smaller in scale and their products are mainly concentrated in the mid- to low-end fields. In recent years, the market competitiveness of domestic barium titanate has been continuously improved and has penetrated into foreign-funded MLCC manufacturers such as Samsung.

微信扫一扫打赏

微信扫一扫打赏