Background and overview[1]

P-trifluromethylaniline (abbreviated as PTFMA, CAS registration number: 455-14-1) is an important chemical raw material, especially widely used in pesticides and medicines. After chlorination of p-trifluoromethylaniline, 2,6-dichloro-p-aminotrifluorotoluene can be obtained. It is an important intermediate and is used in the pesticide industry to synthesize the highly efficient and low-toxic insecticide fipronil (Ruijin). (Special), fluvalinate, flufluuron, herbicides etbuflufen, etfoflufen, etc., which are used in the pharmaceutical industry to synthesize new immunosuppressant drugs such as leflunomide. With the continuous deepening of research on green chemical technology and new drugs, new uses are continuously being developed, and it has become an important chemical product with development prospects.

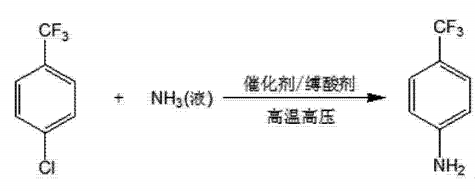

Preparation[1-2]

Report 1,

A production method of p-trifluoromethylaniline: p-chlorotrifluorotoluene and liquid ammonia are reacted in an autoclave in the presence of alcohol and a catalyst, p-chlorotrifluorotoluene, liquid ammonia, alcohol, The amounts of catalyst used are: 950kg of p-chlorotrifluorotoluene, 450kg of liquid ammonia, 800kg of alcohol, and 80kg of catalyst. The reaction temperature is 140-150°C, the pressure is 6-7.5MPa, and the reaction time is 9-13 hours. After the reaction is completed, excess liquid ammonia is absorbed into ammonia water, while industrial alcohol is flashed out, and the catalyst is filtered to remove. The catalyst is regenerated and used. The obtained crude p-trifluoromethylaniline is distilled to obtain 560kg of finished product, and 220kg of raw materials are recovered for one-way conversion. The rate is 66% and the yield is 90%. The above catalyst is composed of the following weight components:

Ferrocene 38%

Triphenylphosphonium 38%

Potassium fluoride 20%

Tetrabutylammonium bromide 4%.

Report 2,

Add 300g p-chlorotrifluorotoluene, 25g cuprous chloride, 10g copper powder, 90g sodium carbonate, 900g polyethylene glycol 300 into the 3L autoclave, seal the autoclave, replace it with nitrogen three times, and then add it to the autoclave. Pour 150g of liquid ammonia into the solution, then raise the temperature to 200°C and the pressure to 10MPa. React at this temperature for 10 hours, then cool to room temperature and filter to remove the insoluble solid. The resulting liquid is distilled under reduced pressure to obtain 150g of unreacted raw material p-chlorotrichloride. Fluorotoluene, and 102g of product p-trifluoromethylaniline. Unreacted raw materials can be recovered and recycled.

Apply[3]

2,6-Dichloro-4-trifluoromethylaniline is an important pesticide synthesis intermediate, mainly used to synthesize fluorine-containing organic pesticides such as fipronil. Here’s how:

Add 200g p-trifluoromethylaniline and 480g dichloroethane into the 3L reaction kettle, control the temperature to 10°C, and add dropwise a solution of 503g sulfonyl chloride and 190g dichloroethane while stirring within 3 hours. After completion, continue the reaction at 50°C for 2 hours. After the reaction is completed, cool down, wash with water, and wash with saturated sodium carbonate aqueous solution to remove the inorganic salts. After the organic phase is concentrated to remove the solvent, 2,6-dichloro-4-trifluoro is obtained by rectification. Methylaniline 144g.

References

[1] [Chinese invention] CN02113194.5 A method for preparing p-trifluoromethylaniline

[2] [Chinese invention, Chinese invention authorization] CN201310385926.2 A method for preparing p-trifluoromethylaniline through high-pressure ammonolysis

[3] [Chinese invention] CN201310385952.5 A method for preparing 2,6-dichloro-4-trifluoromethylaniline

微信扫一扫打赏

微信扫一扫打赏