Background and overview[1]

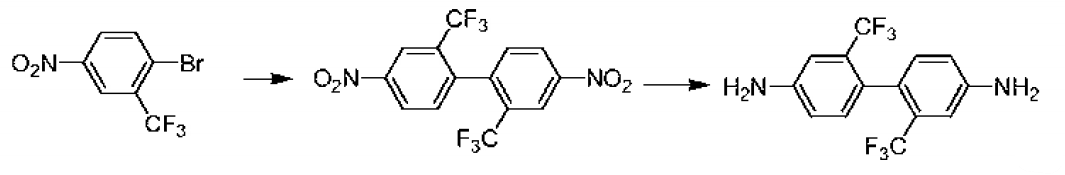

2,2′-bis(trifluoromethyl)diaminobiphenyl is also called 2,2′-bis(trifluoromethyl)-4,4’diaminobiphenyl. 2,2′-bis(trifluoromethyl)-4,4’diaminobiphenyl is mainly used in the fields of microelectronics and optoelectronics to prepare extremely low dielectric constant, extremely low surface free energy, extremely high mechanical strength, Colorless and transparent PI material with extremely high wear resistance is the most well-known monomer among all fluorine-containing PI diamine monomers.

2,2′-bis(trifluoromethyl)diaminobiphenyl is an important monomer for the synthesis of polyimide. The polyimide synthesized with TFMB as the monomer introduces fluorine groups. The element has a small atomic radius and high electronegativity, which allows polyimide to retain excellent comprehensive properties while giving it many unique properties, such as thermal stability, chemical inertness, excellent mechanical properties, etc.

Preparation[2]

(1) Copper powder activation: Add 100g copper powder and 20g iodine to 500mL acetone, stir at room temperature for 1 hour, let stand for precipitation, filter, add the filter cake to 400mL hydrochloric acid (37%) – acetone volume ratio is 1:1 solution, stir for 0.5h, filter, wash with acetone, and vacuum dry to obtain activated copper powder.

(2) Coupling reaction: Under nitrogen protection, add 270g (1mol) 2-bromo-5-nitrotrifluorotoluene and 128g (2mol) into a 2L reaction bottle equipped with a stirrer and a reflux condenser. Activated copper powder, 11.1g (0.05mol) copper bromide, 19.8g (0.1mol) phenanthroline, 1L anhydrous N,N-dimethylformamide, heated to 100°C, react for 10 hours, while hot Filter, wash with methanol, concentrate to remove the solvent, and recrystallize using 300 mL of methanol. 136g of yellow solid was obtained, with a yield of 85%.

(3) Hydrogenation reaction: Dissolve 136g of 2,2′-bistrifluoromethyl-4,4′-dinitrobiphenyl obtained in step (2) in ethanol to obtain a solution with a concentration of 30% , then add 6.8g of 5% Pd/C catalyst, mix evenly, and continuously feed it into the microchannel reactor. Control the liquid flow rate to 15mL/min, and introduce hydrogen at the same time. The reactor control pressure is 1.5MPa, and the reactor temperature is 80°C. The solution and hydrogen come into contact with each other in the microchannel reactor. After mixing and reaction, they enter the gas-liquid separator from the reactor outlet. The gas enters the reaction system from the gas phase outlet of the gas-liquid separator for recycling, and the product passes through the liquid phase outlet of the gas-liquid separator. Enter the crude product tank. The crude product is allowed to stand, filtered, concentrated, and recrystallized using toluene to obtain a white solid, which is 2,2′-bis(trifluoromethyl)diaminobiphenyl. The yield is 91% and the purity is 91%. is 99.5%.

References

[1] [China Utility Model] CN201821432307.9 A production system for 2,2′-bis(trifluoromethyl)-4,4’diaminobiphenyl

[2] [Chinese invention] CN201811639731.5 Preparation method of 2,2`-bistrifluoromethyl-4,4`-diaminobiphenyl

微信扫一扫打赏

微信扫一扫打赏