Organic framework membrane is an emerging membrane material. Future industry development challenges and opportunities coexist.

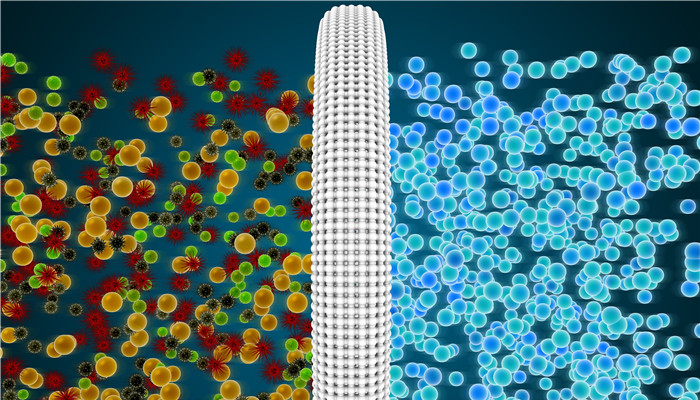

Organic framework membranes, also known as OFMs membranes or Porous materials. Organic framework membranes have the characteristics of high porosity, strong stability, and can be functionalized. In recent years, they have been increasingly used in gas separation, catalysis, energy storage and other fields.

At this stage, the organic framework membranes that have been developed around the world include metal organic framework membranes (MOFs membranes), covalent organic framework membranes (COFs membranes), conjugated microporous polymer membranes (CMPs membranes), and porous aromatic framework membranes (PAFs membranes). ), porous organic cage membranes (POCs membranes) and hydrogen-bonded organic framework membranes (HOFs membranes), etc. Among them, MOFs membranes and COFs membranes are currently the focus of research in the field of organic framework membranes.

According to the “2022-2027 China Organic Frame Film Industry Market In-depth Research and Development Prospects Forecast Report released by the Industrial Research Center, As a new generation of membrane materials, organic framework membranes can be used for carbon dioxide capture and separation, natural gas purification, olefin/alkane separation, and rare gas separation. Under the strategic goals of carbon neutrality and carbon peaking, the organic framework membrane market has broad development space and is expected to In 2026, the global market size of metal-organic framework membranes alone will reach 5.56 billion yuan.

With the continuous deepening of research, the preparation methods of organic framework membranes are gradually enriched. At this stage, the preparation methods of organic framework membranes mainly include in-situ growth method, layer-by-layer self-assembly method, coating method, interfacial polymerization method, suction filtration method, etc. Since organic framework membranes are emerging membrane materials, the five major membrane-making technologies currently have their own advantages and disadvantages. Take the in-situ growth method as an example. The in-situ growth method is currently the most commonly used membrane-making technology for organic framework membranes. It has the advantages of simple operation and easy scale-up. , the membrane skeleton structure is regular, but the disadvantages are long reaction time, low raw material utilization, and high substrate requirements.

Organic framework membranes are the research frontier in the field of gas separation. There are many companies and institutions engaged in related research around the world, including Japan’s National Institute of Materials Research, Japan’s Kyoto University, Japan’s Nanyang Technological University, Singapore’s Nanyang Technological University and other foreign institutions, as well as the Chinese Academy of Sciences, the University of Science and Technology of China, Tianjin University, Hong Kong University of Science and Technology, Dalian Institute of Chemical Physics and other domestic institutions. In terms of commercialization, companies such as Bayer of Germany and Strem Reagents of the United States are commercializing organic framework membranes very quickly. In contrast, the application scale of organic framework membranes in my country is still small, and there is broad room for market development in the future.

Industry analysts said that organic framework membrane is an emerging membrane material. In recent years, with its unique advantages, organic framework membrane has been widely used in gas separation. Applications in fields such as , catalysis, and energy storage are becoming more and more widespread. The organic framework membrane market has broad development space. However, currently, due to limitations of membrane production technology, research level and other factors, the commercialization of organic framework membranes in my country is slow. In the future, there will be both opportunities and challenges for the development of the organic framework membrane industry.

微信扫一扫打赏

微信扫一扫打赏