UV absorber is a kind of light stabilizer, which can absorb the ultraviolet part of sunlight and fluorescent light sources, but does not change itself. Because sunlight contains a large amount of ultraviolet light, it causes harm to colored objects. Its wavelength is about 290-460 nanometers. They are carried out through chemical oxidation and reduction (Redoxreaction), which ultimately decomposes color molecules and prevents harmful ultraviolet light from destroying the color. The methods include physical and chemical. Here is only a brief introduction to chemical methods. Even if ultraviolet absorbers are used to effectively block the protected object, it can also weaken its damage to the color.

UV absorbers must meet the following conditions:

①Can strongly absorb ultraviolet rays (especially wavelength 290-400nm);

②Good thermal stability, not affected by high temperatures even during processing, low thermal volatility;

③Good chemical stability and will not adversely affect the material components in the product;

④Good miscibility, can be evenly dispersed in the material, no blooming, no bleeding;

⑤The absorber itself has good photochemical stability and does not decompose or discolor;

⑥Colorless, non-toxic, odorless;

⑦washable;

⑧Cheap, good quality, easy to get;

⑨Insoluble or poorly soluble in water.

UV absorbers can be divided according to their chemical structures: salicylates, benzophenones, benzotriazoles, substituted acrylonitriles, and triazines. and hindered amines.

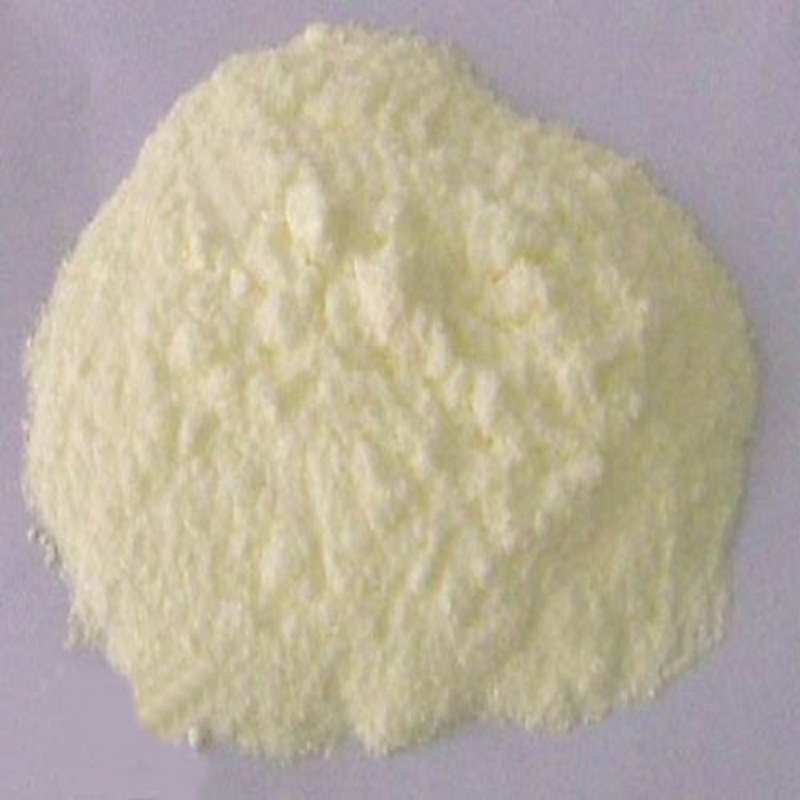

Basf BASF UV absorber TinuvinP is a light stabilizer that can be used for plastics and other organic substances. Its physical form: white to light yellow powder content: 99% , Molecular type: C13H11N3O Application industry: Plastic industry. Powder coating industry. Coating industry. BASF light stabilizer UV-P is a light stabilizer that can prevent UV-P from degrading plastics and other organic materials. It can prevent ultraviolet degradation caused by UV-P, thereby slowing down the yellowing of plastics and the decline in mechanical properties.

Can be used on PVC, polystyrene, polyester, acrylics, vinyl/acrylic polymers, polyurethane, polycarbonate and fibers. Its UV absorber P can be used in conjunction with antioxidants and other light stabilizers to increase the photothermal stability of UV-P to plastics.

Under ultraviolet irradiation, it can protect its degradation, thereby slowing down the yellowing of plastics and the decline in mechanical properties. The material works by selectively absorbing ultraviolet rays from sunlight (the main cause of plastic degradation) and converting them into harmless heat energy. Suitable for PVC, polystyrene, polyester, acrylics, vinyl/acrylic polymers, polyurethane, polycarbonate and fibers. TinuvinP can be used together with antioxidants and other light stabilizers to increase the photothermal stability of TinuvinP to plastics. UV absorber

TinuvinP forms high-color complexes with iron or cobalt ions. In this case, Tinuvin320 or Tinuvin327 is recommended. Redox and reducing agents during the polymerization-vulcanization process do not affect the stability of TinuvinP. TinuvinP has good thermal stability and is suitable for high-temperature processing in ordinary processing environments such as polycarbonate.

Basff UV absorber: C81.770.622.944.326.329.791.UV-P.783.123.292.400.1130.328.384-2.900.5151.5060.477.479.303.3035.

微信扫一扫打赏

微信扫一扫打赏