Phosphorus flame retardantsAccording to the method of use, they can be divided into reactive flame retardants and additive flame retardants. Additive flame retardants are convenient to use and have a wide range of applications. Reactive flame retardants have good compatibility and stable flame retardant effects, and are widely favored by people.

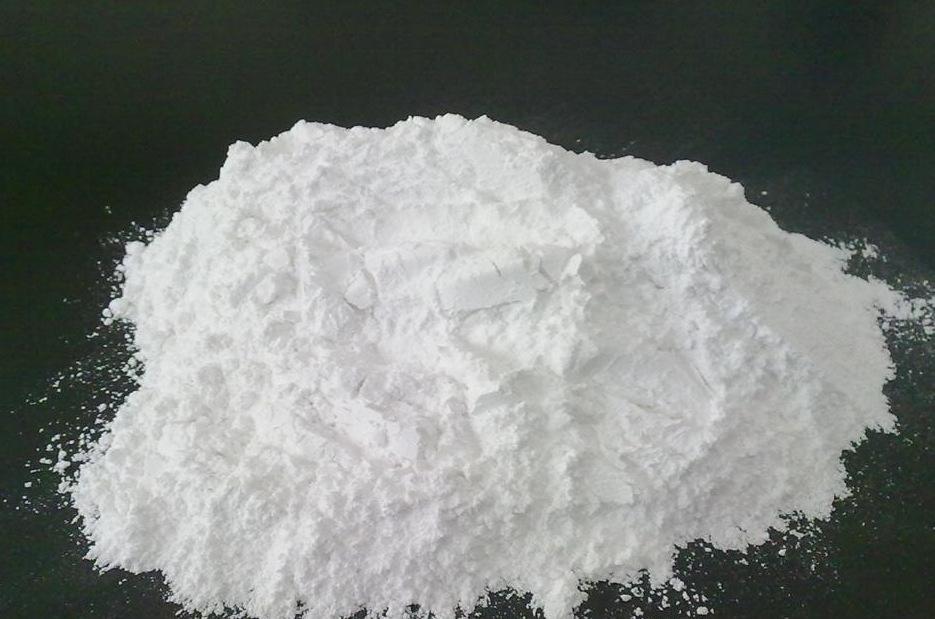

According to the properties and composition of phosphorus flame retardants, they can be divided into inorganic flame retardants and organic flame retardants. Inorganic flame retardants include red phosphorus, poly Ammonium phosphate (APP), etc. Most organic flame retardants are phosphates, phosphonates, phosphine oxides, phosphonites, etc., and there are many types and derivatives of organic flame retardants.

Classified by properties and composition

Inorganic flame retardants

Composition: red phosphorus, ammonium polyphosphate, polyphosphate, ammonium phosphate

Features: Simple to use, easy to mix with other flame retardants, but low water resistance, poor compatibility with polyolefins, and easy migration

Organic flame retardants

Composition: triphenyl phosphate, tricresyl phosphate, propylbenzene phosphate, butylbenzene phosphate, toluene diphenyl phosphate

Features: It has dual functions of flame retardant and plasticizing. Since organophosphorus flame retardants are mostly oily and have poor compatibility with the substrate

Classified by usage

Added flame retardants

Composition: most inorganic flame retardants, organic flame retardants and synergistic flame retardants

Features: Added during polymer processing, the amount of flame retardant can be controlled and the ratio of flame retardants to other additives can be adjusted

Reactive flame retardant

Composition: vinyl derivatives, halogen-containing compounds, hydroxyl-containing derivatives, epoxy compounds

Features: As one of the monomers during the polymerization process, the flame retardant structure is added to the molecular chain, and the flame retardant effect is stable.

Phosphorus flame retardants are widely used in common plastics. In addition to adding inorganic flame retardants or organic flame retardants separately, they are sometimes added Organic/inorganic flame retardants are used in different proportions, or synergistically with flame retardants containing other elements to form a stable carbon layer structure. The main methods for applying phosphorus flame retardants in plastics include synergistic methods and organic addition methods. , inorganic addition method, reaction flame retardant method, microencapsulation, ultrafine nanotechnology, etc., are widely used in polystyrene, polypropylene, polyurethane and nylon, etc.

微信扫一扫打赏

微信扫一扫打赏