Background and overview[1][2]

L-Phenylalanine is a physiologically active aromatic amino acid. It is one of the amino acids that humans and animals cannot naturally synthesize by themselves. It is one of the eight essential amino acids in the human body’s metabolism; it is mainly used for: ( 1) Safely used in any food and beverage; used in food, can be added to baked goods to enhance the nutritional effect of phenylalanine; it also undergoes amino-carboxylation reaction with sugars to improve the flavor of food and supplement the needs of the human body Functional food amino acid balance; it is the main raw material for the synthesis of the dipeptide sweetener Aspartame (Aspartame); (2) used in medicine, it is an intermediate for amino acid anti-cancer drugs such as phenylalanine and formic acid sarcomatin. It is also a raw material for the production of epinephrine, thyroxine and melanin. It is an important component in the preparation of amino acid infusions and comprehensive amino acid preparations, and is used to synthesize antiviral drugs, vitamin B6, etc.

In recent years, aspartame has become the most popular sweetener product in the international market and has been widely used in the food and beverage industries, so it has become the biggest driving force for the surge in demand for L-phenylalanine.

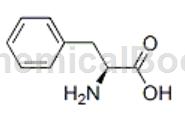

Physical and chemical properties and structure[1]

The chemical name of Phenylalanine is α-amino-β-phenylalanine, its molecular formula is C6H5C2H3(NH2)CO2H, and its molecular weight is 165.19. The main products include L-phenylalanine, D-phenylalanine and DL-phenylalanine. The main application fields are the food and pharmaceutical sectors. L-phenylalanine is white crystal or crystalline powder, slightly bitter, melting point 283°C (decomposition), specific rotation -35.1° (C=1.94, in water), sublimates under reduced pressure, soluble in water, and insoluble in methanol , ethanol, ether, etc.

L-Phenylalanine is one of the 8 essential amino acids, and it is also an important raw material for the synthesis of tyrosine in the body. Phenylalanine is a necessary ingredient for certain amino acid drugs and amino acid nutritional foods, and is an intermediate in the synthesis of certain anti-cancer drugs, such as phenylalanine, formic acid sarcolysin, etc. Its most important use is to synthesize the dipeptide product Aspartame (APM) with L-aspartic acid; another important use of L-phenylalanine is as a nutritional fortifier, amino acid infusion and complex amino acid Ingredients of the preparation.

L-phenylalanine is an essential amino acid for humans and animals. It is of great use in the fields of medicine, food, health products and other fields. It is the main raw material for the production of the globally popular new sweetener Aspartame (APM). L-phenylalanine is the amino acid variety with the fastest growing market demand since the 1980s. 90% of the product is used in the production of aspartame sweeteners and 10% is used in medicine and other aspects. L-phenylalanine is mainly used in the pharmaceutical industry for amino acid infusions and amino acid drugs, such as anti-tumor drugs p-fluorophenylalanine, phenylalanine, sarcolytic acid, etc. The market is very tight and the future development prospects are bright. . At present, my country’s pharmaceutical industry consumes about 400 tons of L-phenylalanine every year and mainly relies on imports.

At present, due to the development and utilization of domestic amino acid infusions and anti-cancer drugs, especially the restrictions on saccharin production and the troubles faced by stevia sweetener products, the demand for aspartame has surged, which has greatly stimulated and promoted The production and development of L-phenylalanine. The preparation methods of L-phenylalanine mainly include direct fermentation, chemical synthesis and enzymatic methods.

The direct fermentation method uses raw materials such as glucose to directly produce L-phenylalanine through microbial fermentation; the chemical synthesis method has a long route, many by-products, and the product is an optical racemate, which requires optical resolution and is costly. ; Enzymatic production uses synthetic precursors of L-phenylalanine such as phenylpyruvic acid or cinnamic acid to synthesize L-phenylalanine through enzyme catalysis in microbial cells. In the process of producing L-phenylalanine by fermentation method, the fermentation broth needs to be extracted to obtain L-phenylalanine. The extraction method currently used is mainly the ion exchange method, but the ion exchange resin used is macroporous. Strongly acidic styrene-based cation exchange resin, this resin is difficult to separate L-phenylalanine from fermentation broth, and the yield can reach up to 40% and the purity can reach up to 50%.

L-phenylalanine

Preparation [2]

L-phenylalanine conversion solution flocculation plate and frame filtration, simulated moving bed ion exchange extraction, and one-time crystallization productionRecovery of product and mother liquor, each process step specifically includes:

Step 1. L-phenylalanine conversion solution flocculation plate and frame filtration

①Prepare filter aids and flocculants:

Prepare the filter aid under normal temperature conditions. In a 5T reactor, add 2.5T of water and add 120kg of filter aid, one or more of pearlescent sand, silica bath soil or perlite, and set aside.

Preparation of flocculant: In a 30T reaction kettle, add 15T of water, raise the temperature to 65°C, add 280kg of one or more of the flocculants polyacrylamide, aluminum sulfate or polyaluminum chloride, and stir After dissolving, cool to 25°C; set aside.

② Make pre-coating: Stir the filter aid evenly and then drive it into the frame to form a pre-coating. The thickness of the pre-coating is 3mm; set aside. Stir the filter aid evenly and then pour it into the plate and frame to form a pre-coating on the filter cloth of the plate and frame. The thickness of the pre-coating is 0.5 to 8 mm.

③ Flocculation of L-phenylalanine conversion liquid: In the 20T conversion liquid of L-phenylalanine produced by phenylpyruvate enzymatic method, add 2000L of flocculant and 60L of filter aid prepared above, and stir for 15 minutes. After that, let it sit for 45 minutes.

④ Filter the flocculated material liquid through the pre-coated frame to remove microbial cells and their fragments to obtain a filtrate. The turbidity of the filtered solution is 80 NTU, the light transmittance is 56%, and the yield is 99.0%.

Step 2, simulated moving bed ion exchange extraction

Take 10m3 of the filtrate obtained in step 1, the concentration of L-phenylalanine is 15g/L, enter the ion exchange system at a feed rate of 3m3/h, control the adsorption pH value at 1.8, and the adsorption time is about 2.5h Afterwards, backwash impurities for 25 minutes with pure water at a flow rate of 5m3/h, then heat the 0.5mol/L eluent liquid alkali to 40°C, and remove the L adsorbed on the resin at a flow rate of 2.5m3/h. – After phenylalanine is eluted, the jacket needs to be kept at 80°C. When the pH is 2.5, the high flow of the eluent starts to be collected and stops when the pH is 10.8. The light transmittance of the eluate was 54.0%, and the yield was 98.9%.

Step 3: Crystallize the product in one go

Take 9m3 of the eluent obtained in the above step 2, with a concentration of 32.5g/L, concentrate and evaporate ammonia for 35 minutes, circulate the material liquid through a filter cake made of waste activated carbon, filter for 45 minutes, and then pump the material liquid into the decolorizer tank, add 10kg of activated carbon, the decolorization temperature is 68°C, the pH value is 5, the decolorization time is 30 minutes, filter, concentrate, crystallize and dry to obtain 290.2kg of L-phenylalanine crystals, with a yield of 99.2% and a purity of The light transmittance is 99.6%, the light transmittance is 99.5%, the specific optical rotation is -34.0°, and the limited indicators are all qualified.

Step 4. Recovery of mother liquor

Take the mother liquor obtained after extraction in step 3, add water to dilute it to a concentration of 15g/L, then filter it through the flocculation plate and frame. Prepare the filter aid pearlescent sand, the flocculant polyacrylamide and prepare the plate and frame according to the requirements of step 1. Pre-coating, the thickness of the pre-coating is 3mm; add the flocculant polyacrylamide and the filter aid pearlescent sand to the mother liquor, stir it, filter it through the formed pre-coating frame to remove impurities, and then pass the filtered solution through the separation , concentrated crystallization, etc. The purity of the product is 99.0%, the transmittance is 99.0%, the specific optical rotation is -33.6°, and the limited indicators are all qualified.

Main reference materials

[1] Cui Jiandong, & Zhang Yanan. (2008). Research progress on the enzymatic synthesis of l-phenylalanine by phenylalanine ammonia lyase (pal). Chinese Journal of Bioengineering (s1), 301-305.

[2] Liu Yangsheng, Dai Youyuan, & Wang Jiading. (1999). Extraction of l-phenylalanine with di(2-ethylhexyl)phosphoric acid. Acta Chemical Engineering, 50(3), 289-295.

[3] Xu Weijian, Liu Yutang, Xiang Weizhong, Xiong Yuanqin, Lu Yanbing, & Liu Huijun. (2004). Preparation and performance study of L-phenylalanine molecularly imprinted polymer. Journal of Hunan University (from Science Edition), 31(4), 1-5.

微信扫一扫打赏

微信扫一扫打赏