Background and overview[1-2]

With the continuous expansion of the application fields of epoxy resin adhesives, various new and special requirements are increasing day by day, and there is an urgent need for an epoxy resin adhesive that can cure quickly at low temperatures. However, the epoxy resin adhesives currently used have low activity and long curing times. It usually takes about ten hours for 1 to 10 g of materials to be completely cured at room temperature, so it is difficult to meet the requirements for rapid repair. According to literature reports, hydroxyl-containing substances can greatly promote the epoxy reaction. If hydroxyl groups can be directly introduced into the epoxy resin structure, the effect will be better. According to reports in the literature, the addition of resorcinol to excess epichlorohydrin under the catalysis of benzyltrimethylamine bromide improves the activity of the epoxy group. When 1,4-cyclohexanedimethylamine is used The reaction speed during curing is more than ten times higher than that of bisphenol A epoxy resin. However, due to the high cross-linking density of resorcinol diglycidyl ether (also known as resorcinal epoxy resin, hereinafter referred to as resorcinol diglycidyl ether), the cured product becomes very brittle. , and because the cross-linking speed is too fast, the mobility of the molecular chain is limited. When cured to a certain extent, the chain segments freeze, preventing further reaction between the resin and the curing agent, and the actual degree of curing is reduced. At the same time, too fast cross-linking density often causes people to mix the curing agent during construction and then fail to solidify it. Therefore, the mechanical and thermal properties of adhesives made from pure resorcin diglycidyl ether are not ideal, and the construction is also very inconvenient. It is not as good as bisphenol A epoxy resin. Therefore, resorcin diglycidyl ether is not as good as bisphenol A epoxy resin. Ethers are rarely used alone as epoxy adhesives.

Application [3-6]

Resorcinol diglycidyl ether is mainly used as an adhesive. Examples of its applications are as follows:

1) Prepare a solvent-free epoxy-Sima adhesive, consisting of component A and component B with a mass ratio of 1-4:1; wherein component A consists of component A with a mass ratio of 100: 10-80: 10-50: 5-10: N, N, N’, N’-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl] of 10-30 Composed of propane epoxy resin, resorcinol diglycidyl ether epoxy resin, reactive diluent, aromatic diamine and tetramaleimide resin; component B consists of mass ratio 20:50-100:5- It is composed of 10 resorcinol diglycidyl ether epoxy resin, m-xylylenediamine and tetramaleimide resin. The invention has a simple synthesis process, is environmentally friendly, has excellent comprehensive performance, can be used for bonding glass, ceramics, metals, epoxy resin-based composite materials and other base materials, has high bonding strength, and has broad market prospects.

2) Prepare a special sealant for solar photovoltaic modules, which is composed of the following raw materials by weight: polydimethylsiloxane: 90 parts, white carbon black or titanium dioxide: 8 parts, phthalate Dibutyl formate or triphenyl phosphate: 18 parts, resorcinol diglycidyl ether or ethanol: 12 parts, acrylamide: 7 parts, phthalic anhydride: 4 parts, aluminum hydroxide or magnesium hydroxide: 13 parts, glass fiber or asbestos fiber with a maximum size of 0.05mm: 30 parts, antioxidant D: 4 parts, methylparaben: 2 parts, methyltrimethoxysilane or ethyltrimethoxysilane, etc.: 5 share. The invention also discloses its preparation method. The invention has the advantages of greater tensile strength, higher elongation at break, greater volume resistivity, higher dielectric strength, stronger adhesion, better resistance to yellowing and cracking, and longer shelf life. Effect.

3) Prepare a highly conductive and corrosion-resistant composite material, including the following weight components: 4-8 parts of cobalt naphthenate, 3-7 parts of lanthanum acetylacetonate, 7-12 parts of copper powder, and silver oxide 2-6 parts, titanium boride 3-7 parts, calcium carbonate 2-5 parts, bornyl acetate 15-20 parts, tetraallyl silicate 8-13 parts, graphene oxide powder 1-4 parts, m-phenylene 15-20 parts of diphenol diglycidyl ether, 10-15 parts of 3,4-dimethoxybenzyl alcohol, and 6-10 parts of p-aminobenzene sulfonamide. The prepared composite material has excellent electrical conductivity and corrosion resistance and has a wide range of applications.

4) Prepare a two-component corrosion-resistant metal repair agent, which belongs to the technical field of polymer materials. In terms of parts by weight, weigh 30 to 40 parts of epoxy resin E-44, 60 to 80 parts of epoxy resin E-51, 15 to 25 parts of resorcin diglycidyl ether, and 18 to 30 parts of modification. Additives, 15 to 25 parts of modified filler, 8 to 16 parts of silane coupling agent, 5 to 10 parts of pretreated borax, 15 to 20 parts of curing agent T-31 and 5 to 12 parts of Glauber’s salt, epoxy resin E-44 Mix with epoxy resin E-51, add resorcinol diglycidyl ether, stir and mix to obtain a mixed resin, stir and mix the modified additives, modified fillers, silane coupling agent and pretreated borax to obtain a mixed material , mix the mixture with the mixed resin to obtain component A; mix isocyanate, curing agent T-31 and Glauber’s salt to obtain component B, and package A and B components separately to obtain a two-component resistant product. Corrosion metal repair solution. The resulting product has excellent mechanical properties and good corrosion resistance.

Preparation[1-2]

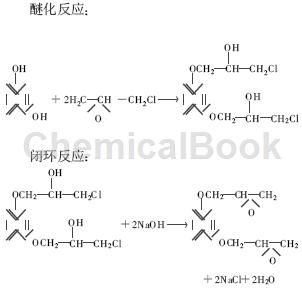

Method 1: Resorcinol and epichlorohydrin react according to the following formula under the action of sodium hydroxide:

The synthesis process is as follows:

(1) Weigh the resorcinol according to the proportion and add it to the three-necked flask, then add epichlorohydrin and dissolve it into a uniform liquid at 40°C;

(2) Weigh sodium hydroxide (solid) according to the proportion and mix it at 40 ℃.�Add in six times every half hour;

(3) After adding sodium hydroxide, raise the temperature to 50 ℃ and maintain it for 2 hours;

(4) Distill under reduced pressure to remove water and unreacted epichlorohydrin, and the temperature of the material does not exceed 100 ℃;

(5) Extract with benzene, and then filter to remove sodium chloride and excess sodium hydroxide;

(6) Remove benzene by distillation under reduced pressure to obtain resorcinol diglycidyl ether

Method 2: Using triphenylphosphorus as the etherification catalyst and powdered sodium hydroxide as the ring-closing agent, resorcinol diglycidyl ether (RDGE) was synthesized. Its epoxy value is 0.80 and its viscosity at 25°C The curing exothermic peak is about 15°C lower than that of bisphenol A epoxy resin (E51), as measured by differential scanning calorimeter (DSC). RDGE has a very significant diluting effect on E51. The blending of the two greatly improves the overall performance of general epoxy resin. When using 593# curing agent, the tensile strengths of RDGE and E51 are 75.17 MPa and 58.58 MPa respectively. The former is 28% higher than the latter. The tensile strength of the blended cured product of RDGE and E51 increases linearly with the increase of RDGE content. ; For the 593# cured RDGE E51 blend system, both the flexural strength and flexural modulus increase linearly with the increase in the amount of RDGE. The flexural strength increases from 112.77 MPa of E51 to 123.75 MPa of RDGE, and the flexural modulus increases from 1.79 of E51. GPa increases to 2.40 GPa for RDGE.

Main reference materials

[1] Synthesis and application of resorcinol diglycidyl ether

[2] Preparation and application of resorcinol diglycidyl ether

[3] CN201310352462.5 A solvent-free epoxy-Sima adhesive and its preparation method

[4] CN201410451611.8 Sealant for solar photovoltaic modules and preparation method thereof

[5] CN201611196613.2 A highly conductive and corrosion-resistant composite material and its preparation method

[6] CN201810397947.9 A two-component corrosion-resistant metal repair agent

微信扫一扫打赏

微信扫一扫打赏