Background and overview[1][2]

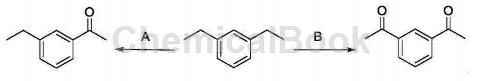

3-Ethylacetophenone is an organic intermediate that can be prepared from the oxidation of 1,3-diethylbenzene.

Preparation method[1-2]

Method 1: Add 0.5 equivalent of NHPI to a 25 mL Schlenk reaction tube, vacuum dry for 15 minutes, put on an oxygen balloon, and add 1 mL of acetonitrile, 1.0 equivalent of tert-butyl nitrite, and m-diethylbenzene in sequence under an oxygen atmosphere. 0.5 mmol, add a polytetrafluoro plug to the reaction tube, put it into an oil bath, and react at 80°C for 24 hours. After the reaction is completed, the solvent acetonitrile is concentrated under reduced pressure and separated by column chromatography. The eluent is petroleum ether/ethyl acetate (v:v=50:1) to obtain 3-ethyl acetophenone. Product yield 80%, light yellow oil; 1H NMR (CDCl3, 400MHz): δ7.77 (t,J=8.0Hz, 2H), 7.35- 7.41(m,2H),2.70(q,J=7.6Hz, 2H),2.60(s,3H),1.26(t,J=7.6Hz,3H);13C NMR(CDCl 3,100MHz): δ198.4,144.7,137.2, 132.7,128.5,127.5, 125.8,28.7,26.6,15.4.

Method 2: In a 100mL three-necked flask, add 13.424g m-diethylbenzene, 1ppm (0.07mg) tetraphenyliron porphyrin, 10ppm (0.86mg) tetrakis-(p-chlorophenyl)cobalt porphyrin, Oxygen was introduced at a flow rate of 40 mL/min, the reaction was initiated at 150°C, and the reaction was carried out at 110°C for 14 hours. The reaction mixture was distilled under reduced pressure to obtain m-ethyl acetophenone. The conversion rate of m-diethylbenzene was 80.2%, the yield of m-ethyl acetophenone was 65.8%, and the purity was 99.1%.

This method uses a very small amount of metalloporphyrin compounds directly as catalysts, which can greatly reduce the energy consumption required for catalyst preparation and the environmental pollution caused by the preparation process. Moreover, because the amount of metalloporphyrin catalyst is very small, there is no need for separation and recovery after the reaction, which avoids the energy consumption of the separation, recovery, and purification processes. At the same time, because metalloporphyrins can be naturally degraded in the environment, no secondary pollution will occur. Metalloporphyrins directly serve as catalysts, and the reaction system is similar to a homogeneous system, which increases the contact probability and reaction efficiency between metalloporphyrins and substrates, and fully reflects the high catalytic activity of metalloporphyrins.

Main reference materials

[1] CN201710381003.8 A method for direct oxidation of benzylic C-H bonds to ketones

[2] CN201010103446.9 Method for preparing m-ethyl acetophenone by bionic catalytic oxygen oxidation of m-diethylbenzene

微信扫一扫打赏

微信扫一扫打赏