Overview[1]

D-Phenylglycine methyl ester is an important intermediate in the synthesis of cefaclor and ampicillin. Cefaclor and ampicillin are semi-synthetic second-generation cephalosporins. Their antibacterial spectrum and antibacterial activity are similar to cefazolin. They are mainly used In the treatment of otitis media, lower respiratory tract infections, urinary tract infections, skin and skin tissue infections, it can inhibit all Haemophilus influenzae, including ampicillin-resistant strains. Although the synthesis patent report process has simple steps, the final product is D-phenylglycine methyl ester hydrochloride. The synthesis of cefurocin and ampicillin requires desalting, which brings tedious processes to the subsequent synthesis, so free D-phenylglycine can be obtained at low cost. Methyl esters and have commercial value.

Preparation[1]

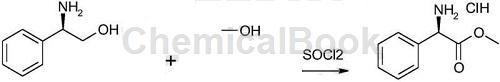

A synthesis method of D-phenylglycine methyl ester, including the following steps:

1) Add methanol and D-phenylglycine to the reaction kettle, cool it to 10-15°C, and slowly add the catalyst concentrated sulfuric acid dropwise into it. The mass ratio of the amount of concentrated sulfuric acid to D-phenylglycine is 1:20- 21. The dripping speed of concentrated sulfuric acid is 1-5kg/h;

2) After the dropwise addition is completed, the temperature is raised to 60-70°C for reaction. After the reaction is completed, the temperature is reduced and concentrated to a slurry. Water is added, and ammonia is used to adjust the pH to 7.5-8.0. The crystal is dried to obtain the product D-phenylglycine. Methyl ester.

Apply[2-4]

D-Phenylglycine methyl ester can be used in organic synthesis. Examples of its applications are as follows:

1) Synthesis of ampicillin. The separation method of macroporous adsorption resin is used to realize the separation of D-phenylglycine from ampicillin, 6-APA and D-phenylglycine methyl ester. D-phenylglycine is not adsorbed by the resin and enters the adsorption residual liquid. The adsorption residual liquid passes through After electrodialysis, reverse osmosis concentration and crystallization, high-quality D-phenylglycine is recovered; while ampicillin, 6-APA and D-phenylglycine methyl ester adsorbed on the resin are analyzed and concentrated through nanofiltration to obtain The nanofiltration concentrate can directly serve as the reaction bottom water in the enzymatic synthesis of ampicillin and then be recycled and reused. The invention comprehensively recovers the active ingredients D-phenylglycine, ampicillin, 6-APA, and D-phenylglycine methyl ester in the enzymatic ampicillin crystallization mother liquor, creates economic benefits, reduces the discharge of high-concentration wastewater, and achieves Environmentally friendly, clean and green production.

2) Prepare cefaclor. The synthesis method of cefaclor includes: in the presence of enzyme, 7·A-C-C-A and D·phenylglycine methyl ester salt derivative form a reaction mixture to react to generate cefaclor, wherein cefaclor is added to the reaction mixture Seed crystal, the seed crystal needs to be added before the cefaclor produced by the reaction is precipitated. This method improves reaction efficiency, shortens the synthesis cycle, increases the conversion rate of 7·A-C-C-A, and improves the purity of the obtained cefaclor.

3) Preparing ampicillin, which includes: 1) Mix 6-APA and D-phenylglycine methyl ester or its salt in water and add it to ampicillin synthase at a pH value of is 5.5~7.5, and the reaction is carried out at a temperature of 10°C~30°C; 2) Adjust the product obtained in step 1) with acid until the solution is clear, keeping the pH value at 0.5~2.0, and the temperature at 10°C-30°C; 3) Cool the solution obtained in step 2) to 12°C~15°C, then adjust the pH to 3.00~3.50, then lower the temperature to 5°C~6°C, and maintain the pH value at 3.50; then adjust the pH to 4.9~5.0 and lower the temperature to 1°C~ Maintain at 2°C to obtain ampicillin crystals. The invention greatly improves the yield and quality of ampicillin products, improves production efficiency and ensures the medication safety of ampicillin products.

Main reference materials

[1] CN201610526124.2 A synthesis method of D-phenylglycine methyl ester

[2] CN201710743701.8 Comprehensive recovery method of active ingredients in ampicillin crystal mother liquor synthesized by enzymatic method

[3] CN201310629212.1 Cefaclor and its synthesis method

[4] CN201410197856.2 An improved preparation method of ampicillin

微信扫一扫打赏

微信扫一扫打赏