Background[3]

Steel is the most commonly used metal in our daily lives. Especially with the advancement of industrialized society, human beings’ use of steel is increasing day by day. However, the reserve content of steel on the earth is limited, and human mineral extraction continues to rise. The annual loss of steel due to corrosion is staggering, resulting in a huge waste of resources. The most common method to prevent steel from rusting is to isolate steel from oxygen. Water and air are the main sources of oxygen in the environment where steel is used, so keep the steel surface dry and avoid direct contact with air. The usual measures are: coating the steel surface with grease, paint, enamel, plastic, etc. You can also use electroplating and other methods to coat a layer of metal that is not easy to corrode, but the cost is higher.

With the advancement of technology, more and more anti-rust agents are used to treat the surface of steel to obtain a rust-proof surface. The anti-rust effect that anti-rust agents can achieve on the surface of steel depends on the degree of protection of the surface of steel. Therefore, anti-rust on the steel surface is to prevent water vapor, oxygen and other corrosive products from invading the steel surface. Nippon Surface Chemical Co., Ltd. has developed a water-soluble detergent and anti-rust agent that has both cleaning and anti-rust functions. It is suitable for anti-rust treatment between automotive metal parts processing processes.

The composition of water-soluble cleaning and anti-rust agents contains carboxylic acid compounds, alkanolamine compounds and diamine compounds. Carboxylic acids and carboxylic acid derivatives are also commonly used reagents in the field of rust inhibitors. Monocarboxylic acid rust inhibitors, namely monocarboxylic acids and their derivatives are R-COOH, and polycarboxylic acids include tricarboxylic acid rust inhibitors (R- COO)nMm.

Carboxylic acids and carboxylic acid derivatives are widely found in nature and contain a variety of components. There are also many reagents that can be used to treat steel surfaces to obtain anti-rust protective surfaces, which can be divided into aliphatic carboxylic acids and aromatic carboxylic acids. , commonly used are: fatty acids of animal and vegetable oils, stearic acid, oleic acid, cinnamic acid, formic acid, propionic acid, petroleum ester, crotonic acid, maleic acid, oxalic acid, fumaric acid, benzoic acid, naphthoic acid, phthalic acid Dicarboxylic acid, isophthalic acid, alkenylsuccinic acid, methylbutyric acid, ethylvaleric acid, cyclopropanecarboxylic acid, 2-methylcyclopentanecarboxylic acid, trans-1-cyclohexanedicarboxylic acid, 4 -Chlorobenzoic acid, o-bromobenzoic acid, m-nitrobenzoic acid, etc. These carboxylic acids are cheap and easy to obtain and can achieve anti-corrosion and anti-rust effects on steel surface treatment. They also have anti-oxidation and aging effects, so they are widely used in anti-rust agents.

Application and preparation[1][2]

Some research has developed an environmentally friendly microemulsified monocarboxylic acid rust inhibitor and its preparation method. The environmentally friendly microemulsified rust inhibitor is prepared according to the following method: molar ratio of C12-C18 monocarboxylic acid: urea 2 -4. Weigh C12-C18 carboxylic acid and urea for later use; add 100 parts of C12-C18 carboxylic acid, 10-20 parts of Span 80, 10-20 parts of sodium petroleum sulfonate, 10-20 parts of n-amyl alcohol, Add 10-20 parts of alkylphenol polyoxyethylene ether to the stirrer in sequence, heat to 50-80°C, stir thoroughly until the solution is transparent, and prepare mixture A; dissolve urea in 25-40 parts by weight of the total mixture % of water, stir and dissolve thoroughly to prepare mixture B; add mixture B to mixture A and stir thoroughly for reaction to obtain an environmentally friendly micro-emulsified rust inhibitor mother liquor; add 10-5 of the prepared mother liquor according to the weight ratio 0 times water and stir thoroughly to obtain an environmentally friendly micro-emulsified rust inhibitor working fluid.

The environmentally friendly microemulsified rust inhibitor of the present invention has excellent anti-rust effect. It is used as an excellent inter-process anti-rust agent, with a maximum rust-proof time of up to 3 months, and is energy-saving, emission-reducing and environmentally friendly. There is also research and development of a water-soluble cleaning and anti-rust agent containing carboxylic acid compounds, alkanolamine compounds and diamine compounds. The carboxylic acid compound in the composition is a monocarboxylic acid with 4 to 12 carbon atoms (monocarboxylic acid rust inhibitor/dicarboxylic acid compound). If the number of carbon atoms is less than 4, the anti-rust performance will be reduced; if the carbon number is less than 4, the anti-rust performance will be reduced; If the number of atoms is higher than 12, problems such as separation and foaming of the composition will occur.

Suitable monocarboxylic acid compounds include fatty acids such as valeric acid, heptanoic acid, caprylic acid, nonanoic acid, capric acid, dodecanoic acid, 2-ethylhexanoic acid, and aromatic acids such as benzoic acid and butylbenzoic acid. Suitable dicarboxylic acid compounds include adipic acid, sebacic acid, dodecanedioic acid, etc. The concentration of carboxylic acid compounds is 5 to 20 (mass ratio, the same below). If the concentration of carboxylic acid compounds is lower than 5, the anti-rust performance will be reduced; if the concentration is higher than 20/5, separation of the components will occur.

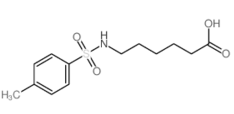

For example, fsail 2128, a commercially available product, is a sulfonamide acid type anti-rust agent (monocarboxylic acid anti-rust agent). It is insoluble in water, but its organic amine salt or alkaline salt is soluble in water. . After neutralization with alkali/alcoholamine, it is a very effective corrosion inhibitor for iron, cast iron and iron alloys. It can be used in all types of water-based metalworking fluids (semi-synthetic and synthetic fluids). It has a synergistic effect with usail 7042 (copper corrosion inhibitor); it has a synergistic effect in anti-corrosion performance when used in combination with three types of fungicides.

Used in metalworking fluids, industrial cleaning agents, water-based hydraulic fluids, water treatment processes, lubricants for offshore oil/gas drilling, engine antifreeze (coolant), water-based quenching fluids, water-ethylene glycol flame-resistant hydraulic fluids (hfc), smoothing fluid. Odorless, no sticky residue after the water phase evaporates, low foam, hard water resistance >2000ppm, will not cause aluminum discoloration, will not generate nitrosamines, and has better thermal stability than metal soaps (water-based quenching fluid is suitable). General��Use triamine to adjust ph>8.5 to improve solubility, and use appropriate heating (<80℃) to accelerate dissolution. If quantitative determination is required, take 45wt% fsail 2128 and 55wt% tri-amine and stir at 70°C until transparent. It is recommended to be used in conjunction with usail 7042 metal deactivator for synergistic effect.

Main reference materials

[1] He Dandan. Anti-rust agent technology in invention patent application. Scientific and technological innovation and application, 2018

[2] Cai Jiqing. Water-soluble detergent and anti-rust agent[J]. Corrosion and Protection, 2003, 24(8): 363-364.

微信扫一扫打赏

微信扫一扫打赏