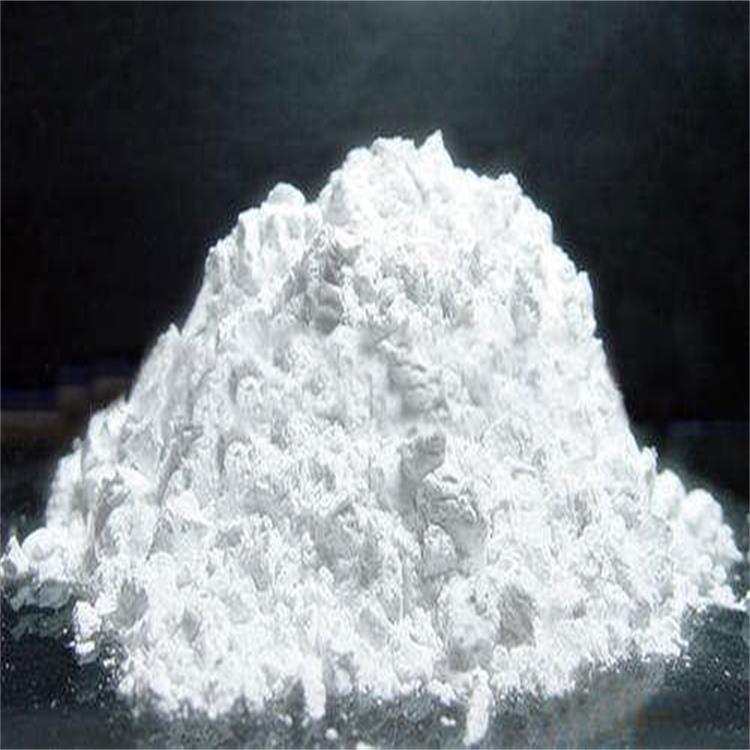

Silk black is a very special type of carbon black. In addition to having the properties of other carbon blacks, silica also has It has the characteristics of high temperature resistance, non-flammability and excellent electrical insulation. It has been widely used in many industries. Vapor phase silica is one of the extremely important new high-tech ultrafine inorganic materials. Due to its small particle size, it has a large specific surface area, strong surface adsorption, large surface energy, and high chemical purity. It has good dispersion properties, special properties in thermal resistance, electrical resistance, etc. With its superior stability, reinforcement, thickening and thixotropy, it has unique characteristics in many disciplines and fields and plays an irreplaceable role.

Vapor phase silica, commonly known as “Nano silica“, is widely used in various industries as additives, catalyst carriers, petrochemicals, and decolorization Agents, matting agents, rubber reinforcing agents, plastic fillers, ink thickeners, metal soft polishing agents, insulation fillers, advanced daily cosmetic fillers and spray materials, medicine, environmental protection and other fields. It also provides new material foundation and technical guarantee for the development of related industrial fields. Because it shows special functions compared with conventional materials in terms of magnetism, catalysis, light absorption, thermal resistance and melting point, it has received great attention. Below, Kain Industrial Additive will introduce several applications of silica black.

Rubber In rubber production, silica black is mainly used to reinforce colored rubber to meet the needs of white or translucent products. White carbon black also has super strong adhesion, tear resistance, heat resistance and anti-aging properties, so it can also replace part of carbon black in black rubber products to obtain high-quality rubber products, such as off-road tires, engineering tires, Radial tires, etc.

The pigment silica can be used to change the surface properties of organic pigments. This is because organic pigments have strong color and tinting power. However, it cannot compete with inorganic pigments in terms of light resistance and heat resistance. By adding fumed silica Greatly improve the various properties of organic pigments, including anti-aging, brightness, hue and saturation, etc. The transformed organic pigments are not only of high quality but also have an increasingly wider range of applications.

微信扫一扫打赏

微信扫一扫打赏