The demand for heat dissipation in electronic products increases, and the market for high thermal conductivity insulation materials has huge room for development.

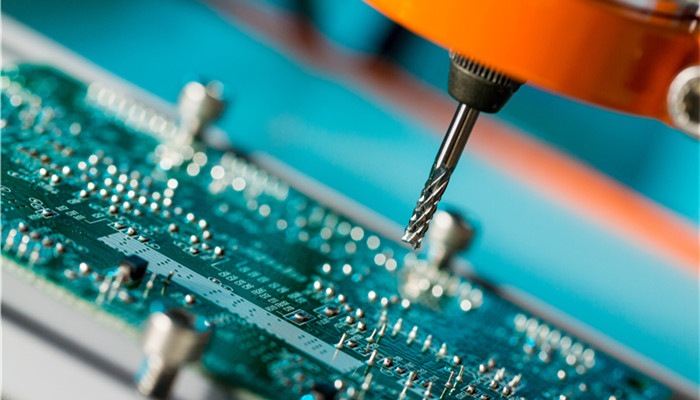

High thermal conductivity insulating materials can be used for heat dissipation in electronic equipment and have broad application prospects in electric vehicles, electronic packaging, LED packaging, aerospace, military, automobiles, household appliances and other fields. High thermal conductivity insulating materials are expected to solve the heat dissipation problem of electronic device structures. In the context of the rapid development of the electronics industry, the market attention of high thermal conductivity insulating materials is constantly increasing.

In recent years, thanks to the improvement of R&D capabilities and in-depth research, the types of high thermal conductive insulating materials have become increasingly diverse, including AlN ceramics, alumina ceramics and other ceramic-based thermal insulating materials, high thermal conductive epoxy resin, high thermal conductive silicone rubber, and high thermal conductive silicone grease. , high thermal conductivity filler and other filled high thermal conductivity insulation materials.

Miniaturization, high power, high integration, and density are important development trends for electronic products and automotive chips. At the same time, the heat generated within the unit volume of electronic devices is also increasing rapidly, and heat accumulation will cause the aging and failure of the insulating dielectric. This reduces the service life and reliability of electronic devices. Against this background, the demand for electronic heat dissipation is increasing day by day, and the market for high thermal conductivity insulation materials has huge room for growth.

According to the “2023-2027 China High Thermal Conductivity Insulating Materials Market Monitoring and Future Development Prospects Research Report released by the Industrial Research Center , Globally, companies related to high thermal conductivity insulation materials include American Berquist Company, Japan’s Zhongyuan Chemical, Japan’s Kyowa Chemical, Japan’s Panasonic, Sinopec Technology, Aochuan Technology, Goldberg Technology, etc. In recent years, thanks to technological progress, more and more highly thermally conductive insulation materials have entered the market, such as nano thermally conductive insulation materials, highly oriented thermally conductive fillers, new thermally conductive resins, etc.

After years of research and accumulation, my country’s types of high thermal conductivity insulation materials have become increasingly rich. However, there is still a certain gap compared with Europe, Japan, the United States and other countries in terms of technology, raw material supply, cost control, performance, etc. The market for high-end high thermal conductivity insulation materials has long been dominated by foreign countries. Enterprise monopoly. In the future, Chinese companies still need to increase investment in the research and development of high thermal conductivity insulation materials and develop more high-performance high thermal conductivity insulation materials, so as to achieve domestic substitution of high-end high thermal conductivity insulation materials.

Thermal conductive silicone grease is a grease-like polymer material that uses organic silicone as the base, adds thermally conductive fillers and various additives, and is mixed and ground. my country is a country with a large demand for thermal conductive silicone grease. It is expected that the domestic thermal conductive silicone grease market will grow at an average annual compound growth rate of about 9.0% from 2023 to 2027.

Industry analysts said that high thermal conductivity insulation materials are expected to solve the heat dissipation problem of electronic device structures. In the context of the upgrading of the electronics industry, high thermal conductivity insulation The materials market has broad room for development. With the deepening of research, the types of high thermal conductivity insulation materials are becoming increasingly abundant. However, compared with Europe, the United States and Japan, the research and technical level of high thermal conductivity insulation materials in my country is lagging behind. In the future, domestic enterprises will need to increase investment in research and development to improve technology levels and their own competitiveness.

微信扫一扫打赏

微信扫一扫打赏