Toluene diisocyanate (TDI) can undergo a trimerization reaction under catalytic action to form a trimer containing isocyanurate ring.TDI trimer has the advantages of low volatility, low toxicity, high functionality, good thermal stability, good corrosion resistance and so on, and it is often used as a polyurethane curing agent in coatings and adhesives. In the 1970s, many foreign companies began to industrialize the production and application of these products, such as Bayer, BASF, Dow and so on. At present, high-performance TDI trimers with low free monomer still need to rely heavily on imports.

In this study, the catalyst NT CAT P100 was used to synthesize TDI trimer polyurethane curing agent, and the experimental results showed that the catalyst has the advantages of fast catalytic rate, high activity, low reaction temperature, etc. The catalyst was used to synthesize TDI trimer polyurethane curing agent at 40 ℃ by dropwise reaction. The catalytic reaction was carried out dropwise at 40 ℃, and the end point of the reaction was reached in 8 h. The TDI trimer was obtained with low free monomer content.

Raw materials and reagents

TDI(80/20): industrial product, BASF; Butyl acetate: analytical pure, Guangzhou Panyu Li-Fortified Factory; NT CAT DMP-30: industrial product, Shinden Chemical; NT CAT K-15: industrial product, Shinden Chemical; NT CAT P100: Shinden Chemical;

Synthesis process

Under nitrogen protection, 100 g of TDI (80/20) monomer and 100 g of butyl acetate were added to a dry four-necked round-bottomed flask equipped with stirring, a thermometer, and a reflux condenser tube, and the mixture was stirred for 5-10 min, heated to 40 ℃, and then 0.5 g of catalyst was added dropwise to a solution of butyl acetate (10 mL of butyl acetate). After dropping, the temperature was controlled between 40 and 80 ℃, and the reaction was kept warm for about 8 h. The -NCO value of the reaction solution was measured every 1 h. When the content of -NCO was reduced to 8.5%-9%, 1 g of benzoyl chloride was added, and the reaction was continued for 0.5 h. After stopping the heating and stirring, the material was discharged at reduced temperature, and a light-yellow transparent liquid was obtained.

On the basis of the above process, a preset amount of alcohol was added dropwise, and the reaction was kept warm for 30-60 min to modify the TDI trimer.

Influence of catalyst type, dosage and dropwise addition method

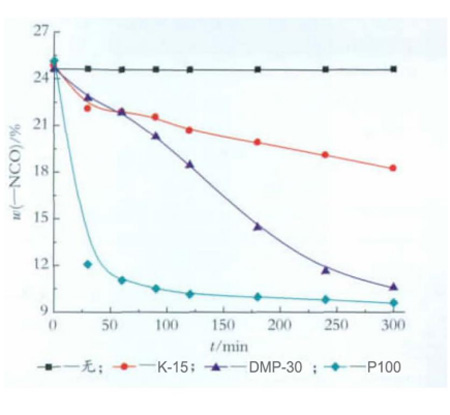

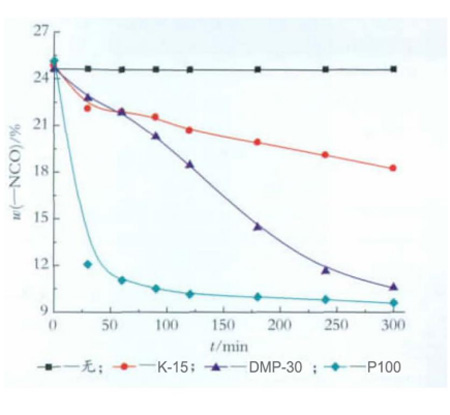

The selection of catalyst is the key to the TDI trimerization reaction. Commonly used TDI trimerization catalysts include tertiary amines, organometallic compounds, organophosphine compounds, alkali metal carboxylates and so on. DMP-30, K-15 and P100 were selected to catalyze the reaction on 50% butyl acetate TDI solution respectively, and the results are shown in Table 1 and Figure 2.

Table 1 Effect of different catalysts (0.5% addition) on TDI trimerization reaction

Catalyst type None K-15 DMP-30 P100

Reaction temperature/°C 70 80 70 70

Reaction time/h 24 26 6 5

w(-NCO)/% 24.2 12.3 10.4 6.8

Product Appearance Colorless transparent Yellow transparent Slightly yellow transparent Nearly water white transparent

From Table 1 and Figure 2, it can be seen that the trimerization reaction of TDI does not occur without catalyst; K-15 catalyzes the trimerization poorly, with higher temperature and longer reaction time, which tends to produce more polymer structure; DMP-30 and P100, both tertiary amine catalysts, catalyze the reaction better, compared to the catalytic performance of P100, which has stronger catalytic performance, and can react quickly and reduce the -NCO value in a short time. The catalytic performance of P100 was better than that of DMP-30 and P100, which were both tertiary amine catalysts. Therefore, P100 was chosen as the catalyst. Figure 3 shows the effect of P100 catalyst on the TDI trimerization reaction when the amount of P100 catalyst accounted for 2%, 0.5% and 0.8% of the total mass of TDI monomer, respectively.

Fig. 2 Comparison of catalytic efficiency of three catalysts

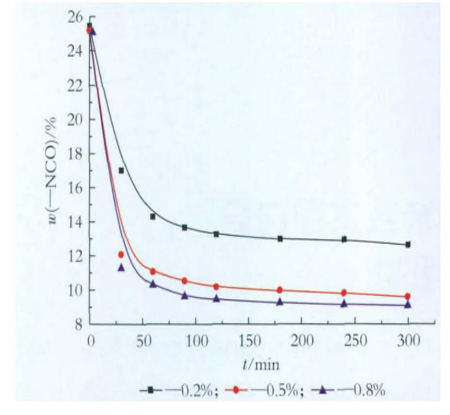

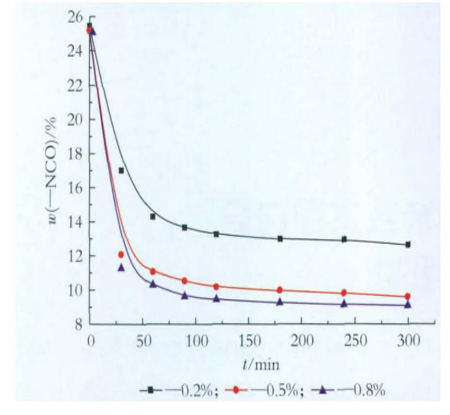

As seen in Fig. 3, with other conditions being the same, the reaction rate was accelerated with the increase of P100 dosage, while the content of -NCO group was reduced. When the catalyst dosage was too low, the -NCO content was still higher than 12% even if the reaction time was extended; while when the catalyst dosage was too high, a large amount of residual catalyst affected the performance of the product to some extent. The experiments showed that the dosage of P100 was more suitable at 0.5%.

Figure 3 Effect of catalyst dosage on TDI trimerization reaction

In addition, the dropwise addition of catalyst will also affect the trimerization reaction. Experiments show that if the catalyst is added at one time, the monomer immediately reacts violently, with a large amount of exothermic, and the local temperature can rise by 10 ℃, and the increase of reactant activity may lead to the increase of the relative molecular mass of the product, broaden its distribution, and generate a large number of polymers, which increases the viscosity of the product, deepens the color, and decreases the product performance. The reaction temperature can be well controlled by using butyl acetate to dilute the catalyst and then adding drop by drop.

Conclusion

P100 was used as the catalyst for the synthesis of TDI trimer, and the experiments showed that the catalytic activity of this catalyst was high, the catalytic rate was fast, and the catalytic effect was better than that of DMP-30 and K-15.

Company Name:

|

Newtop Chemical Materials (Shanghai) Co., Ltd.

|

Sales Manager:

|

Hunter

|

E_Mail:

|

|

Telephone:

|

86-021-5657 7831

|

Fax:

|

86-021-5657 7830

|

Address:

|

Rm. 1104, No. 258, Songxing West Road,

Baoshan District, Shanghai, China (Mainland)

|

Website:

|

|

微信扫一扫打赏

微信扫一扫打赏