Overview[1]

Phenyl ether ketone is an intermediate for the production of pesticides. The wastewater generated during the production process contains major pollutants such as COD, SS, m-dichlorobenzene, and Cl-. Due to its complex composition and content of refractory substances, phenyl ether ketone wastewater is high-salt wastewater, and the wastewater has high salt content. Without pretreatment, it will have a great impact on subsequent biochemical treatment. Therefore, the high-salt wastewater is first evaporated and salted out. The wastewater after evaporating salt is then processed through the process of “micro-electrolysis + air flotation + anaerobic tower reactor + O/A”. The COD removal rate after treatment is 78%. , m-dichlorobenzene removal rate is 80%, SS removal rate is 50%, Cl- removal rate is 90%, meeting the sewage treatment plant takeover standards.

Apply[2-3]

Phenyl ether ketone is an intermediate for the production of pesticides. Application examples are as follows:

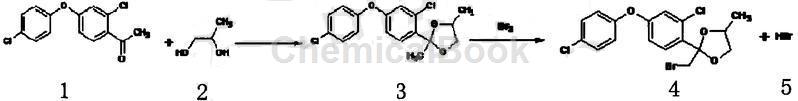

1) Preparation of difenoconazole bromide ketal. Difenoconazole is a new high-efficiency fungicide with a broad bactericidal spectrum. It is effective against Ascomycetes, Basidiomycetes and other species including Alternaria, Ascospora, and Cercospora. Deuterospora, Acanthosporium, Coccidioides, Phytophthora, Cylindrospora, Septoria, and Black Star, Powdery mildewaceae, Pucciniales and some Seed-borne pathogens have long-lasting protective and therapeutic effects. It is also very effective against grape anthracnose and white rot. Specifically, phenylene ether ketone is used as raw material, and the key intermediate of difenoconazole, a new high-efficiency fungicide, is obtained through cyclization reaction and bromination reaction.

2) Preparing difenoconazole, the method includes step 1, heating and dehydrating difenoconazole and 1,2 propylene glycol in the presence of a catalyst and a solvent, and cooling after the reaction; step 2, the cyclized product The initiating reaction occurs under the action of the initiator and bromine accounting for 5% of the total, and then the bromination reaction is carried out with bromine and kept warm. After the reaction is completed, it is washed, dehydrated and discharged; step 3. In the composite catalyst, solvent butanone Under the reaction system, sodium triazole is used as raw material to synthesize the crude difenoconazole. By improving the process route, the process is simple, the process steps and reaction time are shortened, the yield is increased, the product purity reaches 90%, the reaction conditions are mild, energy is saved, the reaction by-products are few, and it is green and environmentally friendly.

Main reference materials

[1] Case Study on Wastewater Treatment of Phenyl Ether Ketone Production

[2] CN201810595511.0 A new synthesis process of phenylene ether bromide ketal

[3] CN201210104542.4 A new preparation method of difenoconazole

微信扫一扫打赏

微信扫一扫打赏