The trend of wafer thinning is rising, and the development of the temporary bonding adhesive (TBA) industry is ushering in a period of opportunity.

Temporary bonding adhesive, referred to as TBA, refers to an intermediate layer material used to bond functional wafers and temporary carrier boards. It generally has low cost, high adhesion, good thermal stability, strong corrosion resistance, and resistance to mechanical stress. Excellent features. After development in recent years, a variety of temporary bonding adhesive products have appeared on the market, such as hot-melt temporary bonding adhesive, thermally degradable temporary bonding adhesive, thermoplastic temporary bonding adhesive, etc.

With the rapid development of information technology, the demand for low-energy consumption, small size, and ultra-thin chips continues to increase, which in turn drives the demand for ultra-thin wafers to continue to rise. Ultra-thin wafers are soft and fragile, so a holding system and support system are needed to ensure that thin wafers can be processed on the equipment. The temporary bonding and debonding process is a key technology for holding and supporting wafers, and it has been widely used in actual production.

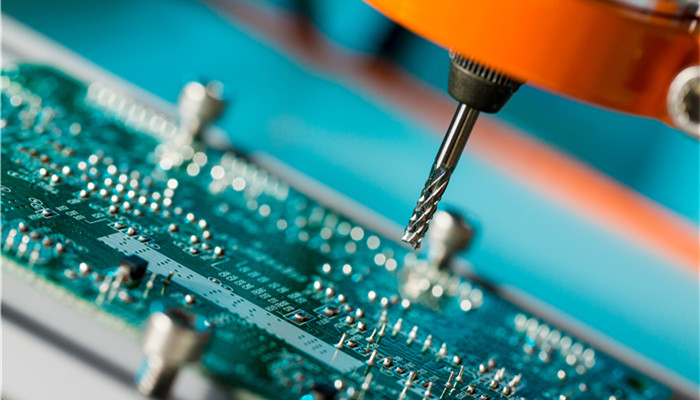

The principle of temporary bonding/debonding technology is to temporarily bond the wafer to a carrier plate with the same diameter through temporary bonding glue, and use the carrier plate to support and transport the thin wafer for subsequent thinning and TSC manufacturing. Maintain stable dimensions during the process, and after the process is completed, the carrier is separated from the wafer to obtain an ultra-thin wafer. As the trend of wafer thinning continues to rise, the popularity of temporary bonding technology continues to increase, which in turn drives the demand for temporary bonding glue to continue to increase.

According to the“Temporary Bonding Adhesive (TBA) Industry Market In-depth Research and Investment Prospects Forecast Analysis Report 2023-2028” released by the Industrial Research Center It shows that the global temporary bonding adhesive market size will be approximately US$220 million in 2022, a year-on-year increase of 8.6%. Globally, the major companies in the temporary bonding adhesive market include 3M, DuPont, Dow Corning, Brewer Science, TOK, Micro Materials and other international companies, as well as Taiwan Daxing Materials, Shenzhen Huaxun Semiconductor Materials, Zhejiang Ao Chinese companies such as Shouma Technology, Hubei Dinglong Holdings, Yunnan Optoelectronic Accessories, Shenzhen Advanced Electronic Materials, and Huajin Semiconductor Packaging Leading Technology.

Temporary bonding glue has high technical barriers, and its bonding strength, chemical stability, thickness and flatness have a direct impact on wafer processing. Affected by technological development, the global market is currently dominated by two companies, 3M of the United States and Taiwan’s Daxing Materials. Their combined market share has exceeded 40%, indicating a high degree of industry concentration.

Industry analysts said that the temporary bonding adhesive industry in mainland China started relatively late and has now achieved scale. The number of mass-produced companies is still relatively small. For example, in February 2023, the client verification of Dinglong’s temporary bonding adhesive products was nearing completion, and the introduction of mass-produced products is in progress. In the future, as the research and development process of domestic enterprises continues to accelerate, the localization level of my country’s temporary bonding adhesive market is expected to accelerate, and the industry has huge development potential.

微信扫一扫打赏

微信扫一扫打赏