nano coating technology has a wide range of applications and my country’s industry concentration is high

nano coating is a surface treatment technology that uses nanotechnology to deposit a layer of thin film material on the surface of another material to improve the performance of the material. nano-coating can improve the corrosion resistance, wear resistance, oxidation resistance and high temperature resistance of materials, and is widely used in aerospace, automobile manufacturing, electronic and electrical, packaging materials and other fields. according to different substrates, nano coatings can be divided into oxide coatings, nitride coatings, metal coatings and alloy coatings.

chemical vapor deposition (cvd), plasma enhanced chemical vapor deposition (pecvd), and physical vapor deposition (pvd) are the more representative nano-coating technologies. pecvd nano-coating technology has the advantages of fast deposition rate, can be applied to various complex-shaped substrates, low deposition temperature, and flexible operation. it has broad application prospects in electronic products that are not resistant to high temperatures. in recent years, the maturity of my country’s pecvd technology has continued to improve, and the localization process of related equipment markets has accelerated, which provides favorable conditions for the development of the nano coating industry.

the main raw materials of nano coating include nano silicon dioxide, nano titanium oxide, etc. nanosilica, also known as white carbon black, refers to silica with a particle size range of 1~100nm. nano-silica has the advantages of good fluidity, uniform particle size, strong surface adsorption capacity, and large specific surface area, making it an ideal raw material for nano-coating. in the early stages of industry development, my country’s nanosilica companies concentrated on producing mid- to low-end products, and high-end products were highly dependent on imports. in recent years, with the technological innovation of local enterprises, the market share of domestically produced high-end nano-silica has further increased, which has accelerated the development of the nano-coating industry.

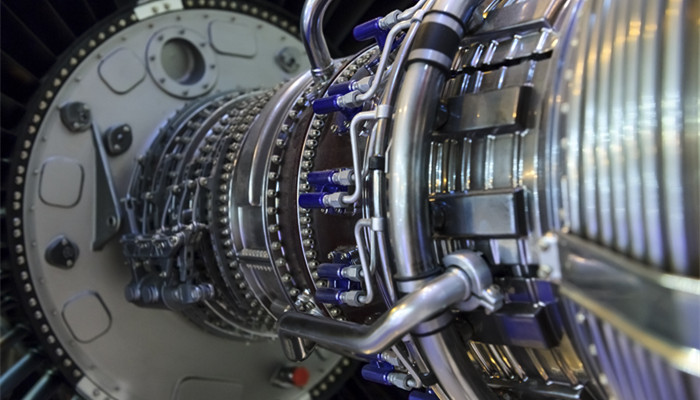

according to the “2023-2028 china nano coating industry market in-depth research and development prospect forecast report released by the industrial research center, nanometer coating is widely used in aerospace, automobile manufacturing, electronic and electrical, packaging materials and other fields. in the field of aerospace, nano-coating can be used on the surface of aircraft fuselage and wings, which can effectively improve the corrosion resistance, high temperature resistance and anti-oxidation performance of the aircraft surface; in the field of automobile manufacturing, nano-coating can improve the anti-static and ultraviolet resistance of the car surface. , anti-fouling and other properties.

my country’s nano-coating industry has a high degree of concentration, with major market participants including fivotech, yongding, crystal materials chemicals, and nashi new materials, etc. fivotech is my country’s leading nano-coating company and has reached cooperation with well-known mobile phone companies such as xiaomi and huawei to provide them with complete coating services.

industry analysts said that as a new surface treatment technology, nano-coating has broad application prospects in many fields. benefiting from the improvement of technological maturity and the improvement of raw material quality, the development speed of my country’s nano coating industry continues to accelerate. in the future, as local companies continue to exert their efforts, my country’s nano coating market space will be further expanded.

微信扫一扫打赏

微信扫一扫打赏