With continued favorable downstream applications and policies, my country’s PVD coating materials market continues to expand.

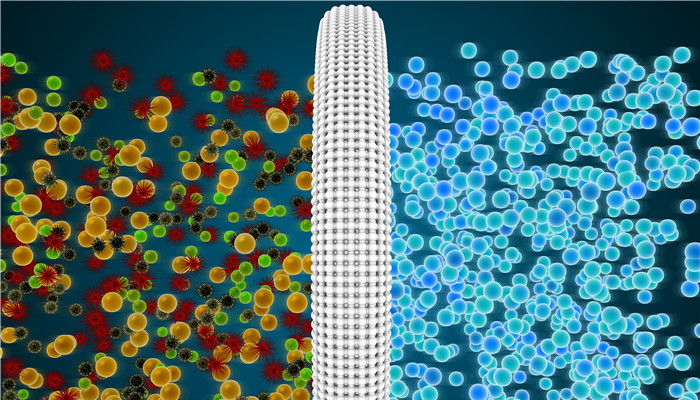

Physical vapor deposition technology, referred to as PVD technology, is one of the main technologies for preparing thin film materials. It refers to the process of vaporizing the surface of an object into gaseous atoms/molecules or partially ionizing it into ions under vacuum conditions, and passing through low-pressure gas. In the physical vapor deposition process, the substances used to prepare thin film materials are collectively called PVD coating materials.

PVD coating materials are new materials that are strongly encouraged and supported by our country. They can effectively improve the hardness, wear resistance, lubricity, color, metallic texture, service life, chemical corrosion resistance, appearance decoration and other properties of the coated objects. It is widely used in LED, semiconductors, tool modification, optical instruments, energy-saving glass, sanitary ware, food packaging, solar cells, optical components, hardware bags, opto-magnetic recording media, flat-panel displays, electronic component films, high-end decorative supplies, etc. field.

According to the “2023-2028 PVD Coating Materials Industry Market In-depth Research and Investment Prospect Forecast Analysis Report” released by the Industrial Research Center, From the perspective of the downstream consumption structure of PVD coating materials in my country, photovoltaics, magnetic materials, integrated circuits, cutting tools, and medical equipment are the main application areas of PVD coating materials. Among them, photovoltaics is the largest application field of PVD coating materials in my country, accounting for 27.5% of the total consumption of PVD coating materials; followed by magnetic materials, accounting for 23.4%; and thirdly, integrated circuits, accounting for 18.6%.

The PVD coating materials industry is a strategic emerging industry. In recent years, in order to encourage the development of strategic emerging industries, enhance the international competitiveness of my country’s emerging industries, improve the innovation and technology level of my country’s enterprises, and assist the development of important new material industries such as PVD coating materials, the Chinese government has successively Policies such as the “Guiding Opinions on Expanding Investment in Strategic Emerging Industries to Cultivate and Strengthen New Growth Points and Growth Pole” and the “Guidance Catalog for Industrial Structural Adjustment (2019 Edition)” were launched. Against this background, my country’s PVD coating materials industry has broad development prospects.

The Asia-Pacific region has the world’s largest PVD coating service market, accounting for about 49.2% of the global PVD coating service market share, providing a very favorable market environment for the rapid development of the PVD coating material industry. With the rapid development of my country’s semiconductor, flat panel display, electronic information, optical components, solar cells and other industries, the market demand for PVD coating materials continues to rise. In addition, with the continuous advancement of my country’s physical vapor deposition technology and the continuous upgrading of processing equipment, the types of PVD coating materials in my country continue to increase, the scope of applications continues to expand, and the market size continues to increase.

my country’s PVD coating materials market size was 21.78 billion yuan in 2018 and 32.54 billion yuan in 2022, with a compound annual growth rate of 10.6%. Among them, my country’s PVD coating materials market size will increase by 13.9% in 2022 compared with 2021. Industrial analysts said that physical vapor deposition technology has high barriers to entry and high product added value, requiring a large amount of financial and material resources to be invested in product research and development. , most of the global PVD coating materials market is in the hands of a few companies, and the market concentration is high. At present, Japan’s Tosoh, Japan’s Nippon Mining Metal, the United States’ Honeywell, the United States’ Praxair, the German Shitaike, Ningbo Jiangfeng Electronics, Beijing Youyan New Materials, Fujian Ashi Innovative Materials, Luoyang Longhua Heat Transfer and Energy Saving, etc. It is a major manufacturer of PVD coating materials in the world.

微信扫一扫打赏

微信扫一扫打赏