Downstream applications have driven the rapid development of adsorption and separation materials in my country, and the high-end product market has broad prospects.

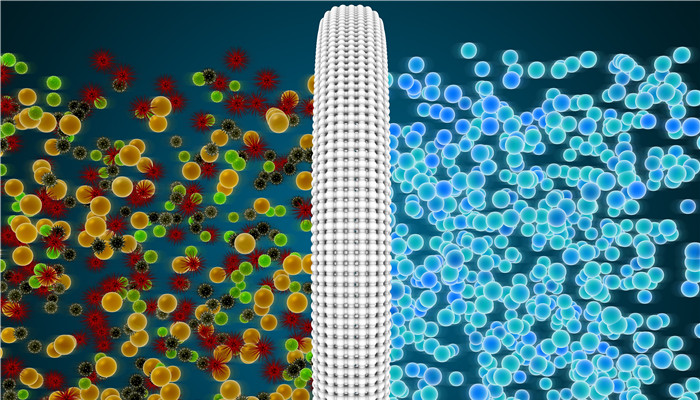

Adsorption and separation materials are functional polymer materials that my country focuses on supporting the development. They have precise and selective adsorption capabilities and can achieve separation, desalination, purification, concentration, refining, purification, decolorization and other material separation and separation through adsorption, exchange, chelation and other processes. purification purposes. Adsorption separation materials can be divided into three categories: one-dimensional materials, two-dimensional materials and three-dimensional materials according to different material scales.

Adsorption separation materials mainly include chelating resin, adsorption resin, enzyme carrier resin, ion exchange resin, etc. Adsorption separation materials are widely used in drinking water, water treatment and ultra-purification, food processing, biomedicine, life sciences, energy conservation and environmental protection, metal resources, hydrometallurgy, chemical industry and catalysis, industrial water treatment, nuclear industry, food, electronics It plays an important role in industries such as components and salt lake lithium extraction.

In order to support the development of strategic emerging industries, ensure the long-term development momentum of strategic emerging industries, and promote high-quality development in the field of new manufacturing/new materials, the Chinese government has successively issued the “New Materials Industry Development Planning Guide” and “The 14th Five-Year Plan for Strategic Emerging Industries”. Several documents such as “Industrial Development Plan” and “Made in China 2025” have created a good policy environment for the development of adsorption and separation materials.

According to the “China Adsorption and Separation Materials Industry Market In-depth Research and Development Prospects Forecast Report 2023-2028” released by the Industrial Research Center, In recent years, my country’s adsorption separation materials have developed rapidly. On the one hand, adsorption and separation materials have a wide range of applications, bringing a broad market space to the industry. As my country’s scientific and technological level continues to improve, the application fields of adsorption and separation materials have further expanded, and the market demand has continued to expand. On the other hand, under the background of “carbon neutrality” and “carbon peak”, my country’s regulations on air pollution and industrial wastewater discharge have become increasingly strict, and work such as heavy metal pollution control and resource treatment have been continuously promoted, driving the development of adsorption and separation materials. Rapid development.

Globally, the market share of adsorption separation materials is mainly dominated by large foreign companies such as Lanxess of Germany, Dow Chemical of the United States, Sumitomo Chemical of Japan, Mitsubishi Chemical of Japan, and Xi’an Lanxiao Technology New Materials, Zhejiang Zhengguang Industrial Co., Ltd., Jiangsu Suqing Water Treatment Engineering, Zibo Dongda Chemical and other Chinese companies have occupied it. Among them, foreign companies account for about 54% of the global adsorption and separation materials market share, and Chinese companies account for about 46%.

Industry analysts said that although my country’s adsorption and separation material companies currently occupy a considerable global market share, their products are mainly concentrated in the low-end Market, about 90% of the market share of the high-end market is in the hands of established international leading companies such as Germany’s Lanxess and the United States’ Dow Chemical. In the future, as the application fields of adsorption and separation materials in my country gradually upgrade and products gradually develop towards high quality and diversified functions, my country’s high-end adsorption and separation material products have broad prospects for development.

微信扫一扫打赏

微信扫一扫打赏