The continuous basalt fiber market has broad development space, and the production technology of local enterprises needs to be upgraded.

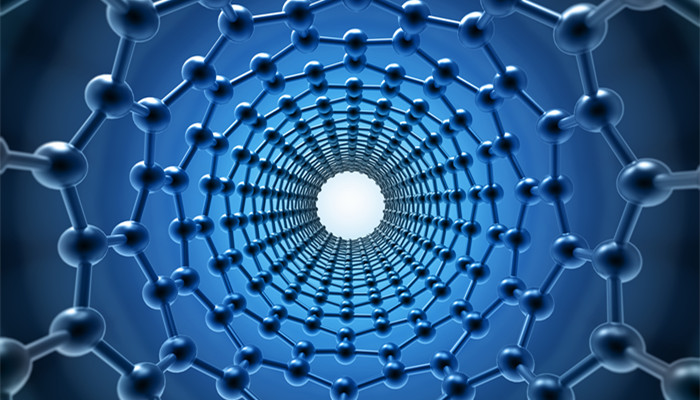

Continuous basalt fiber, referred to as CBF, refers to a type of continuous fiber made from natural basalt ore as raw material through crushing, high-temperature melting, and platinum-rhodium alloy drawing. Continuous basalt fiber has the advantages of excellent mechanical properties, good high temperature resistance, strong acid and alkali resistance, good wave transmittance, green environmental protection, strong oxidation resistance, low hygroscopicity, good insulation, etc., and is similar to carbon fiber, aramid fiber, super High molecular weight polyethylene fiber is ranked among the world’s four major high-tech fiber products.

From the perspective of production technology, the continuous basalt fiber production process is relatively complex. The main production process includes eight links: ore screening, cleaning, crushing, feeding, high-temperature melting, clarification, homogenization, and wire drawing. Among them, high-temperature melting and drawing forming are key links in the production of continuous basalt fiber, which are mainly completed through kiln equipment, including electric combined furnaces and all-electric furnaces.

The electric combined furnace mainly achieves heating through two methods: fuel radiation heating and electric auxiliary heating. Its supporting leaky plate drawing technology has developed to a 1200-hole leaky plate unit furnace drawing process; the all-electric furnace mainly achieves heating through electric heating. The supporting drain plate drawing technology is mostly 200 and 400 hole drawing drain plate unit furnace drawing process. Among them, the equipment used in my country’s continuous basalt fiber production is mostly all-electric furnaces, with a low technical level, and production technology needs to be continuously upgraded in the future.

Continuous basalt fiber has a wide range of applications. At present, with its excellent properties, it has become a key material required in many fields such as construction, automobiles, electronics, chemical industry, medicine, rail transit, aerospace, national defense and military industry. The market demand is huge. Under the current background of continuous development in the domestic continuous basalt fiber application field, its market demand continues to increase, which in turn drives the production to continue to increase. According to the “China Continuous Basalt Fiber Industry Market Monitoring and Future Development Prospects Research Report 2023-2027” released by the Industrial Research Center , my country’s continuous basalt fiber output will reach 28,000 tons in 2022.

As of 2022, the number of continuous basalt fiber-related companies in my country has exceeded 80. However, the number of companies with large-scale mass production capabilities of continuous basalt fiber is still relatively small, less than 20. Representative companies include Sichuan Fiberglass Group, Qianyi Composite Materials, Jiangsu Tianlong, Zhejiang Shijin, and Pawoko Mineral Fiber , Aerospace Tuoxin, Hongyuan Fiberglass Technology, etc.

Industry analysts said that continuous basalt fiber is a key product of the national strategic emerging industries. After years of technological exploration and practice, my country’s single Body furnace wire drawing production technology has been maturely applied, and the number of domestic related companies is increasing. However, compared with leading international companies such as Germany’s DBW, Russia’s SUDAGLASS, Russia’s KamennyVek, and Ukraine’s Kiev Uzhi, Chinese companies are still at a lower level in terms of technology and production equipment. In the future, local companies will need to increase their investment in large-scale kilns and 1,600-hole furnaces. , the research and development efforts of 2400-hole leaky plate have promoted the continuous improvement of domestic continuous basalt fiber production technology.

微信扫一扫打赏

微信扫一扫打赏