The importance of membrane separation technology has become increasingly prominent, and the hydrogen separation membrane market is developing rapidly.

As a type of clean energy with a wide range of sources, hydrogen energy is green and environmentally friendly. Under the background of continuous optimization of domestic energy structure and continuous advancement of dual-carbon goals, its application fields are constantly expanding and market demand is increasing. It is expected that by 2030, my country’s hydrogen The annual demand will reach 38 million tons/year, and the market development prospects are promising. The substantial increase in demand for hydrogen energy has driven the continuous improvement of hydrogen production efficiency, cost, and technical requirements.

There are various types of hydrogen production processes in my country. Currently, hydrogen is mainly produced through two mainstream technical routes: natural gas steam reforming hydrogen production and coal gasification hydrogen production. However, natural gas reforming to produce hydrogen requires decarbonization, and coal gasification to produce hydrogen requires separation and purification. Therefore, seeking efficient decarbonization and separation and purification methods has become the key to improving hydrogen production efficiency. As an efficient decarbonization and purification method, membrane separation technology has the advantages of high processing efficiency and good processing effect, and has become one of the important means of hydrogen production.

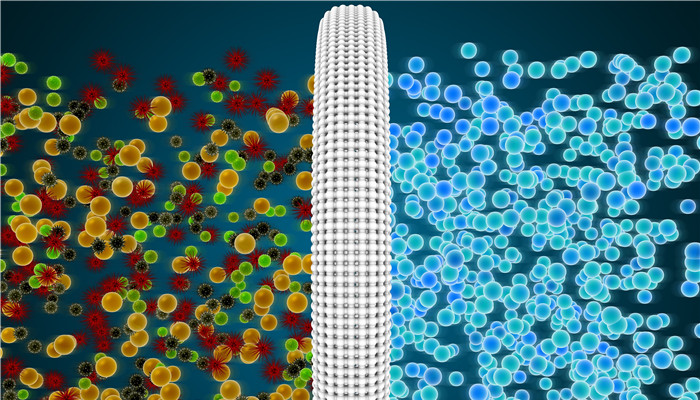

According to the “China Hydrogen Separation Membrane Industry Market Monitoring and Future Development Prospects Research Report 2023-2027” released by the Industrial Research Center , Membrane is the core of the membrane separation process. Hydrogen separation membrane refers to the gas separation membrane product required in the process of purifying hydrogen using membrane separation method. According to different shapes, hydrogen separation membranes can be divided into flat membranes, hollow fiber membranes and spiral wound membranes; according to different working principles, hydrogen separation membranes can be divided into dense metal membranes, inorganic porous membranes, organic polymer membranes, and metal-organic framework membranes. , mixed matrix membrane, etc. Among them, inorganic porous membranes can also be divided into molecular sieve membranes, silica membranes, silicon-based material membranes, etc.

Hollow fiber membrane is the mainstream product in the hydrogen separation membrane market, and its current market share is close to 90%. Experiments using hollow fiber membranes as hydrogen separation membranes first appeared in the late 1960s. After nearly ten years of development, the application range of hollow fiber membranes has continued to expand, and by the late 1970s it had become the mainstream of the hydrogen separation membrane market. The technical barriers to hydrogen separation membranes are relatively high. Currently, the global market is still dominated by three major international companies: DuPont of the United States, Air Liquide of France, and Ube Kosan of Japan.

my country’s hydrogen separation membrane industry started relatively late. Relevant research did not appear until the 1980s, but it developed rapidly. Related self-developed products appeared in the 1990s. Until now, after more than 30 years of development, my country’s hydrogen separation membranes have grown rapidly in the membrane industry. Great progress has been made in structures, membrane materials, membrane modules and other aspects.

Industry analysts said that specifically, in terms of membrane materials, the current hydrogen separation membrane materials in my country are mainly polyamide and polyamide. Imine, the hydrogen separation membrane prepared using such materials has higher hydrogen selectivity and wider operating temperature range; in terms of membrane structure, the domestic hydrogen separation membrane structure has changed from the early flat membrane-based structure to the hollow The fiber membrane-based structure is currently being upgraded towards a spiral-wound membrane structure with a larger specific surface area and higher work efficiency. In the future, as domestic hydrogen separation membrane technology continues to be upgraded, its industry development is expected to continue to accelerate.

微信扫一扫打赏

微信扫一扫打赏