Background and overview[1][4]

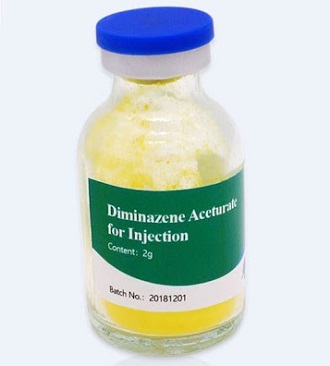

Acetamide triazamidine belongs to the aromatic diamidines and is a traditionally used broad-spectrum anti-hematoprotozoal drug. It has therapeutic effects on domestic animals such as piroplasma, trypanosoma and Anaplasma, but its preventive effect is poor.

Preparation method[1]

The specific production method is: using p-nitrobenzoic acid as raw material, cyanation reaction occurs with p-toluenesulfonamide at high temperature to generate p-nitrobenzene (C7H4N202[619-72-7]. Then from p-nitrobenzoate Addition, amination, reduction, diazotization, coupling and salt formation of nitrobenzonitrile to obtain diethylamide triazamidine. (1) Addition and amination, add p-nitrobenzene, methanol and sodium methoxide Reaction pot, stir to dissolve, and react at 25-30°C for 3 hours. Add ammonium chloride, stir and react at 10-15°C for 5 hours. Recover the methanol to dryness, add dilute hydrochloric acid, boil, and filter to obtain p-nitrophenamidine hydrochloride solution. ; (2) Reduction, heat the above solution to 50°C, add glacial acetic acid, and slowly add iron powder at 60°C. After the addition is completed, raise the temperature to 105°C and react for 5 hours. Filter, and the filtrate is alkalized to pH with sodium hydroxide solution is 12. Filter, and re-acidify the filtrate with hydrochloric acid to a pH of 1-2. Concentrate, cool and crystallize, and filter to obtain p-aminobenzimidine hydrochloride; (3), diazotization, coupling, first add half the amount of p-aminobenzimidine Add aminophenylamidine hydrochloride to water, add hydrochloric acid to dissolve it, add 10% sodium nitrite solution dropwise at -5-0°C, check the end point with potassium iodide starch test paper, add a small amount of the other half of p-aminophenylamidine hydrochloride Add water after mixing, then add saturated sodium acetate to precipitate yellow precipitate. Filter, dissolve the filter cake in water, adjust the pH to 9-10 with 10% sodium hydroxide solution, and precipitate crystals. Filter. Add the filter cake to the reaction kettle , add 400kg purified water, stir, raise the temperature, dissolve at 50-65°C, then lower to 0°C, adjust pH to 9-10 with 10% sodium hydroxide solution, filter, and dry at 60°C to obtain 1,3- Bis(p-amidinobenzene)-triazene; (4), to form a salt, stir the above triazene, acetylglycine, and methanol for 0.5h, adjust the pH to 7 with ammonia water, and heat up to return to dissolution. Add activated carbon, Filter, and the filtrate is cooled and crystallized. Filter and dry to obtain diethylamide triazamidine.

Pharmacological effects[2]

It is effective against trypanosomes, piroplasma and anaplasma (Anaplasma) in domestic animals. After taking the drug, the blood concentration is high, but the duration is short, so it is mainly used for treatment and has poor preventive effect. Its mechanism of action is to selectively block the DNA synthesis or replication of the trypanosome kinetochore and irreversibly combine with the cell nucleus, so that the trypanosoma kinetochore disappears and cannot divide and reproduce.

Clinical Application[2]

It is effective against trypanosomes, piroplasma and anaplasma (Anaplasma) in domestic animals. After taking the drug, the blood concentration is high, but the duration is short, so it is mainly used for treatment and has poor preventive effect. Its mechanism of action is to selectively block the DNA synthesis or replication of the trypanosome kinetochore and irreversibly combine with the cell nucleus, so that the trypanosoma kinetochore disappears and cannot divide and reproduce.

Residue detection[3]

Diacetamide triazamidine is a new type of anti-hematoprotozoal drug that is currently commonly used. It is mainly used for lactating cows. Unreasonable use will cause veterinary drug residues in raw milk, posing certain safety risks.

A method for determining the content of diethylamide triazamidine. The specific detection steps are as follows:

Step 1. Add acidified acetonitrile solution to the test object, homogenize, extract for 0.5-5 minutes, and centrifuge for 2-20 minutes; the acidified acetonitrile can be formic acid acetonitrile, acetic acid acetonitrile, propionic acid acetonitrile and other types of acidified acetonitrile. solution. It is preferred to extract for 0.5-1.5 minutes and centrifuge for 3-6 minutes. In step one, the homogenization, and/or extraction, and/or centrifugation processes may be performed once or multiple times, preferably 2-3 times.

The use of acidified acetonitrile can well precipitate the protein of dairy products, and its separation effect is excellent.

Step 2: Load the supernatant into the solid-phase extraction column, and use at least one alkali solution, at least one alcohol solution, and at least one acidified alcohol solution to elute in sequence, and collect all the eluates; solid-phase extraction The column can be selected from a weak cation exchange column. When a weak cation exchange column is used, an acidic solution needs to be used to elute the item to be tested. During the specific operation of the present invention, it was found that the use of acidic solutions to elute the analyte has a better elution effect than other solvents. The amount of supernatant taken is 50-90% of the total amount. The dosage of the alkali solution, alcohol solution and acidified alcohol solution is 0.5-5 times of the supernatant liquid. The volume ratio of the alkali solution, alcohol solution and acidified alcohol solution is 1:0.8-1.5:0.8-1.5.

Step 3: The eluent is dried and concentrated under protective gas at a temperature of 30-60°C (such as blowing dry with protective gas such as nitrogen), and is diluted to volume with a mixed aqueous solution of acid and acetonitrile; The amount of mixed aqueous solution should be configured according to the needs of the test, or according to the concentration ratio.

Step 4: After filtration, use liquid chromatography mass spectrometry for quantitative analysis; the filtration method can be membrane filtration, filtration using quartz sand, silica gel, seaweed sand, filter paper, etc. as media.

Main reference materials

[1] [Invented in China] CN201310539401.X A production method of triazamidine

[2] Instructions for Triazamidine for Injection

[3] [China invention, China invention authorization] CN201610976684.8 A method for determining triazamidine content in dairy products

微信扫一扫打赏

微信扫一扫打赏