Composite copper foil has great room for cost reduction and the industrialization process continues to accelerate

Composite copper foil is a new type of organic material, which uses PET or PP as a conductive film and copper foil as a coating on both sides. Due to the reduction in copper usage, the cost ratio of composite copper foil raw materials is much lower than that of traditional copper foil raw materials, with a cost reduction of about 50.0%. Therefore, in the context of large-scale production, composite copper foil has greater room for cost reduction. Composite copper foil can improve battery energy density and safety, and has the characteristics of good flexibility, uniformity, and small copper foil thickness. It is one of the most potential current collector materials for lithium batteries.

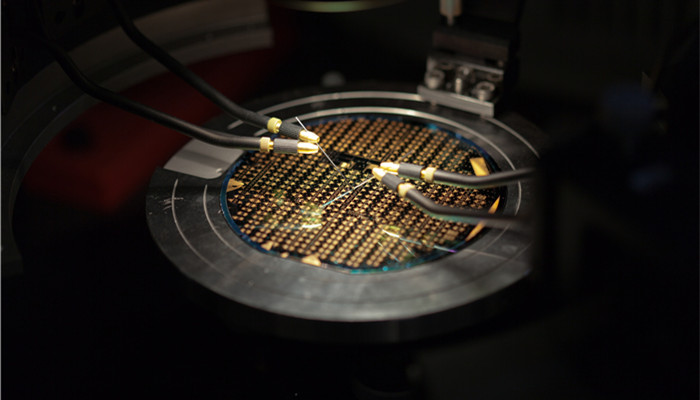

The composite copper foil production process can be divided into one-step method, two-step method and three-step method. Among them, the two-step method is the most mature. The core process involves magnetron sputtering process and water electroplating process. Compared with traditional copper foil production, the preparation process of composite copper foil is more complex and requires higher equipment. Taking into account factors such as base material price, equipment depreciation, yield rate, equipment production speed, etc., the current prices of composite copper foil and traditional copper foil are not much different. In the future, as the preparation process is optimized and the yield rate increases, there will be broad space for cost reduction of composite copper foil, and the substitution effect will be obvious.

Benefiting from the development of new energy vehicles and energy storage industries, battery safety requirements have become stricter, and the market attention of composite current collectors has increased. Composite copper foil has become a mainstream material with its potential, and research hotspots have also continued to increase. In 2021, the number of applications and disclosures related to composite copper foil in my country will reach more than 30. As of now, this number has reached more than 40 in 2022.

According to the “2022-2027 China Composite Copper Foil Industry Market In-depth Research and Development Prospects Forecast Report released by the Industrial Research Center, At present, composite copper foil has not yet achieved mass production. It is expected that the first batch of large-scale production capacity will be released in 2023, and large-scale loading will be achieved in 2024. Against the backdrop of the rapid development of new energy vehicles and energy storage industries, the composite copper foil market will continue to grow and is expected to exceed 11 billion yuan in 2026, when the composite copper foil market penetration rate will reach about 12.5%.

The composite copper foil market is very popular, and the market has attracted many companies, such as Xiamen Haichen, Jinmei New Materials, Chongqing Jinmei, Wanshun New Materials, Zhongyi Technology, Nord Co., Ltd. and other manufacturing companies, Shuangxing New Materials, Base film manufacturers such as Hengli Petrochemical, Kanghui New Materials, and Dongcai Technology, and equipment manufacturers such as Zhenhua Technology, Tengsheng Technology, Dongwei Technology, and Jiaocheng Ultrasound. With the active exploration of relevant enterprises, the composite copper foil market will develop in the direction of ultra-thin, multi-functional and large-scale.

Industry analysts said that due to certain defects in the preparation process and yield rate, the large-scale commercialization of composite copper foil has been slow. Slowly, but as a potential composite current collector material, composite copper foil has a high market presence and R&D enthusiasm, and the number of companies involved is increasing. Composite copper foil has great room for cost reduction. The industry is currently in the early stages of mass production, and companies with rapid mass production will have priority in enjoying market dividends.

微信扫一扫打赏

微信扫一扫打赏