Carbon nanotubes (CNT) are widely used and have good industry development prospects

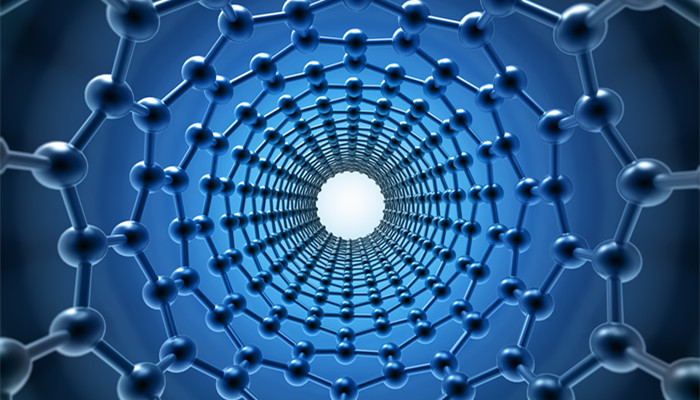

Carbon nanotube (CNT), also known as Bucky tube, is a one-dimensional quantum material with a radial size on the order of nanometers and an axial size on the order of microns, with both ends of the tube basically sealed. Carbon nanotubes have the advantages of good heat transfer performance, lightweight, high modulus, high electrical conductivity, and heat resistance, and are widely used in environmental protection, composite materials, power systems, biomedicine, and electronic devices. According to different structural characteristics, carbon nanotubes can be divided into three types: chiral nanotubes, armchair-shaped nanotubes and zigzag nanotubes.

Carbon nanotube preparation processes include catalytic cracking, arc discharge, semi-continuous hydrogen arc, laser ablation, ion or laser sputtering, solid-phase pyrolysis, etc. The arc discharge method is a traditional preparation process for carbon nanotubes. It places a graphite electrode in a reaction vessel filled with helium gas. Under high temperature conditions, the graphite electrode emits an arc. After the graphite evaporates, carbon nanotubes can be made. In recent years, the semi-continuous hydrogen arc method, as a new process, has been continuously improved on the basis of the arc discharge method, which has increased the output of carbon nanotubes.

The upstream of the carbon nanotube industry chain supplies raw materials, including propylene, N-methylpyrrolidone and liquid nitrogen. As an important chemical raw material, my country’s propylene output continues to grow, laying the foundation for the development of the carbon nanotube industry. In 2021, my country’s propylene output reached 4316.7 million tons, a year-on-year increase of 18.0%; the midstream is the production and manufacturing of carbon nanotube products, including conductive masterbatch and conductive slurry, etc.; the downstream is application fields, including power battery conductive agents, composite materials, biomedical treatment, etc.

The power battery industry is the largest demand side for carbon nanotubes. In recent years, benefiting from the increasing prosperity of the new energy vehicle industry, my country’s power battery market demand has become increasingly strong. According to data released by the China Automotive Power Battery Industry Innovation Alliance, my country’s total power battery production will reach 219.7GWh in 2021, a year-on-year increase of 163.4%. Benefiting from the rapid development of downstream industries, my country’s carbon nanotube conductive slurry shipments continue to increase. According to the “2022-2026 China Carbon Nanotube Industry Market In-depth Research and Development Prospects Forecast Report released by the Industrial Research Center, In 2021, my country’s carbon nanotube conductive slurry shipments will be 82,000 tons, a year-on-year increase of 65.7%.

my country’s carbon nanotube production companies include Qingdao Haoxin New Energy Technology Co., Ltd., Jiangsu Tiannai Technology Co., Ltd., Huizhou Jiyue Nanomaterial Technology Co., Ltd., etc. Tiannai Technology is my country’s leading carbon nanotube company, occupying nearly 45.0% of the market share.

Industry analysts said that carbon nanotubes have a special structure and excellent properties and are called the “king of nanomaterials.” With the rapid development of downstream industries, the scale of my country’s carbon nanotube market will continue to expand. There are many carbon nanotube preparation processes. The semi-continuous hydrogen arc method has the advantages of sufficient utilization of raw materials and high product yield, and is expected to become the mainstream preparation process of carbon nanotubes. As local companies continue to innovate in production technology, the development trend of my country’s carbon nanotube industry will continue to improve in the future.

微信扫一扫打赏

微信扫一扫打赏