Background and overview[1]

Fluorothiophenol is an important pharmaceutical, pesticide and polymer intermediate. It can also be used for the detection of chemiluminescent agents and the preparation of nonlinear optical materials. The existing synthesis method basically involves preparing p-fluorobenzenesulfonyl chloride through sulfonyl chlorination of fluorobenzene, adding water to dilute it, filtering to separate the p-fluorobenzenesulfonyl chloride, and then reducing the p-fluorobenzenesulfonyl chloride to obtain p-fluorobenzenesulfonyl chloride. .

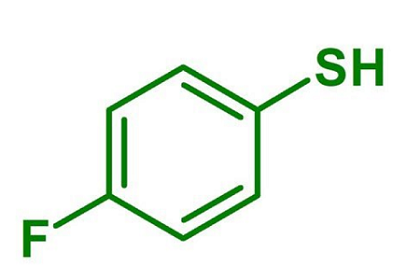

Structure

Preparation[1]

Preparation of p-fluorobenzene is as follows: In a 1000ml four-neck bottle, add 280g (2.4mol) chlorosulfonic acid, cool to 5~10℃, add 29g (0.3mol) fluorobenzene dropwise within 0.5h, and simultaneously Cool in ice bath. After adding fluorobenzene, skim off the ice bath and keep the reaction at 10-20°C for 10 hours. Then slowly raise the temperature to 60°C and keep it for 0.5 hours. The chlorosulfonation reaction is completed. Cool the temperature to 10~15℃, slowly add 400g of crushed ice to dilute the sulfonation solution. The ice adding process should be slow to prevent the material from being flushed and the temperature to rise suddenly, as p-fluorobenzenesulfonyl chloride is easily hydrolyzed. After the above diluted sulfonation liquid is cooled to 10~20℃, slowly add 75g zinc powder and keep the temperature at 10~20℃. After adding the zinc powder, keep it at 10~20℃ for 2 hours, and then raise the temperature to 90℃. React for 2 hours, cool down and filter. The filter cake was washed with 500 ml of water, combined with the aforementioned filtrate, and layered in a separatory funnel. The lower oil layer contained p-fluorothiophenol. The oil layer was distilled under reduced pressure, and after water and impurities were separated, p-fluorothiophenol product was obtained with a yield of 60% and a purity of more than 99% (GC).

Main reference materials

[1] CN200310122130.4 One-pot method for preparing p-fluorothiophenol

微信扫一扫打赏

微信扫一扫打赏