Benefiting from the development of the aerospace industry, the market space for high-temperature protective coatings is huge

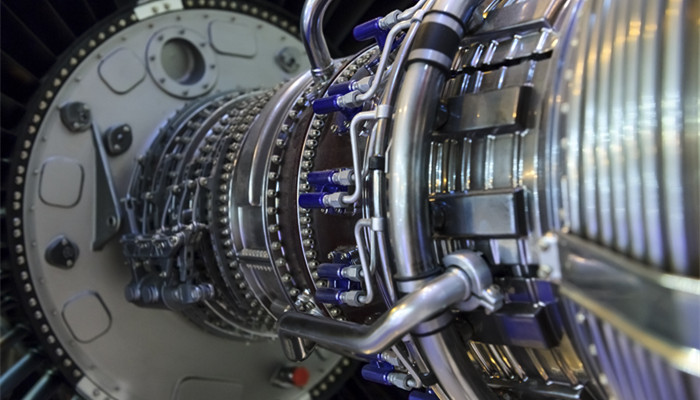

High-temperature protective coatings refer to materials that can protect high-temperature structural components from high-temperature corrosion. They are mainly used in the aerospace field, and aerospace engine hot-end components are an important downstream market. In aeroengines, high-temperature protective coatings can be used for surface coating of turbine blades, combustion chambers and other components. The main product types include diffusion coatings, cladding coatings, thermal barrier coatings, environmental barrier coatings, etc.

According to the “In-depth Market Research and Investment Strategy Suggestions Report on High Temperature Protective Coating Industry 2022-2026” released by the Industrial Research Center, Aero engines are key core components of aircraft. With the development of supersonic speeds in military aircraft, the passenger capacity of civil aircraft continues to increase, the thrust-to-weight ratio of aero engines continues to increase, and the working environment temperatures of turbine blades and combustion chambers continue to rise. Only advanced high-temperature alloys are used. It is difficult to meet the high temperature resistance requirements of components with cooling technology. High temperature protective coatings have become an important material for high temperature protection of hot end components of aeroengines, and performance requirements continue to increase. my country’s military aircraft technology upgrades are accelerating, and civilian passenger aircraft have entered the commercial development stage. High-temperature protective coatings have a broad market space.

High temperature resistant coatings used in the industrial field usually use organic polymer materials, but this type of material has high temperature resistance, high temperature stability, heat insulation, oxidation resistance, corrosion resistance, vibration resistance, impact resistance, and fatigue resistance. It is difficult to meet the technical requirements of high-temperature protective coating for hot-end components of aeroengines. At present, the commonly used high-temperature protective coatings for hot-end parts of aerospace engines are mainly aluminide coatings and improved aluminide coatings (diffusion coatings), MCrAlY coatings, physical vapor deposition porcelain thermal barrier coatings, and A new generation of high-temperature protective coatings—environmental barrier coatings.

Aluminide coatings have poor corrosion resistance and brittleness, and have been replaced by improved aluminide coatings; improved aluminide coatings add a small amount of silicon, chromium, platinum and other elements to the aluminide coating to improve corrosion resistance. Corrosion, anti-flaking and other properties; coating coatings are directly deposited on the surface of high-temperature alloys to form coatings, including metal coatings and ceramic coatings. MCrAlY coating coatings are the main product type, with anti-corrosion, anti-oxidation and The adhesion is improved; Thermal barrier coatings (TBCs) are a combination of ceramic and metal coatings that are coated by physical vapor deposition. They have the advantages of oxidation resistance, high temperature stability, and low thermal conductivity; environmental barrier coatings mainly include Laminated coatings, BSAS coatings, rare earth silicate coatings, etc., materials, technology, and application research are still in depth.

Industry analysts said that at present, almost all aerospace engines around the world are coated with high-temperature protective coatings. After continuous development, The types of high-temperature protective coating products around the world are becoming increasingly diverse. Benefiting from the development of my country’s aerospace industry, the strength of my country’s high-temperature protective coating industry continues to increase. However, there are still gaps between my country’s high-temperature protective coating companies and foreign companies in terms of scale, research and development capabilities, material selection, design, preparation technology, and product performance. . In 2021, the size of my country’s aerospace engine market will be around 27 billion yuan, and it will continue to grow in the next five years. It can be seen that my country’s high-temperature protective coating market has a large space, and domestic enterprises must continuously improve their core competitiveness to compete for the market.

微信扫一扫打赏

微信扫一扫打赏