background and overview[1]

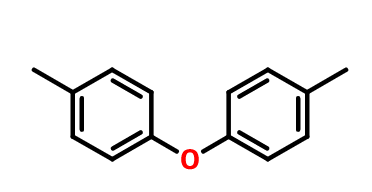

p-xylyl ether is an important pharmaceutical intermediate, for example, it can be used to prepare 4,4′-diphenyl ether dicarboxylic acid. 4,4′-diphenyl ether dicarboxylic acid is used in the electronics and pharmaceutical industries. it is copolymerized with dihydric phenols and other aromatic dibasic acids to form a fully polyarylate thermoplastic liquid crystal polymer (tlcp), which can be used to prepare high-strength, high-modulus liquid crystal fibers, special engineering plastics and polymer flame retardants. it has a wide range of uses in industry.

apply[1-2]

1) a method for preparing 4,4′-diphenyl ether dicarboxylic acid by catalytic oxidation of metal oxides. it includes the following steps: oxidation reaction of p-xylyl ether occurs in a solvent under the action of oxidant, organic metal catalyst, ligand and additive, the oxidation reaction temperature is 85-145°c, and the gauge pressure of the reaction is 1.0-5.0mpa , the reaction time is 5-24h; after the reaction is completed, 4,4′-diphenyl ether dicarboxylic acid is obtained through post-treatment; wherein: the organic metal catalyst is selected from cobalt acetate, manganese acetate, cerium acetate, cobalt nitrate, manganese nitrate , one or two of cobalt acetylacetonate, iron acetylacetonate or cerium ammonium nitrate, and the additive is an alkaline substance. the invention uses metal oxide as the catalyst and hydrogen peroxide, air or oxygen as the oxidant, thereby reducing the manufacturing cost and the generation of three wastes, easing the pressure on environmental protection, and also has the characteristics of easy control and industrial production.

2) a method for preparing 4,4′-diphenyl ether dicarboxylic acid by catalytic oxidation of anderson-type polyacid. the specific steps are as follows: 1) an oxidation reaction occurs between p-xylyl ether, heteropoly acid catalyst, oxidant and additive in a solvent; 2) after the oxidation reaction is completed, filter out the heteropoly acid catalyst and perform extraction to obtain organic and aqueous phases. ; 3) the organic phase is dried, filtered, concentrated and purified in sequence to obtain 4,4′-diphenyl ether dicarboxylic acid; wherein: the heteropoly acid catalyst is an anderson type polyacid precursor or an anderson type polyacid modified precursor. the invention uses anderson type polyacid as a catalyst, has extremely high reaction activity, mild reaction conditions, and is environmentally friendly; has high specific selectivity, is recyclable, and is suitable for industrial production. using hydrogen peroxide, air or oxygen as oxidants can reduce costs, reduce emissions of three wastes, and reduce environmental pressure.

main reference materials

[1]cn201810191980.6 a method for preparing 4,4`-diphenyl ether dicarboxylic acid by catalytic oxidation of metal oxides

[2]cn201810191963.2 a method for preparing 4,4`-diphenyl ether dicarboxylic acid by catalytic oxidation of anderson-type polyacid

微信扫一扫打赏

微信扫一扫打赏