Radiation grafting membrane can improve the performance of traditional membrane materials and have obvious competitive advantages

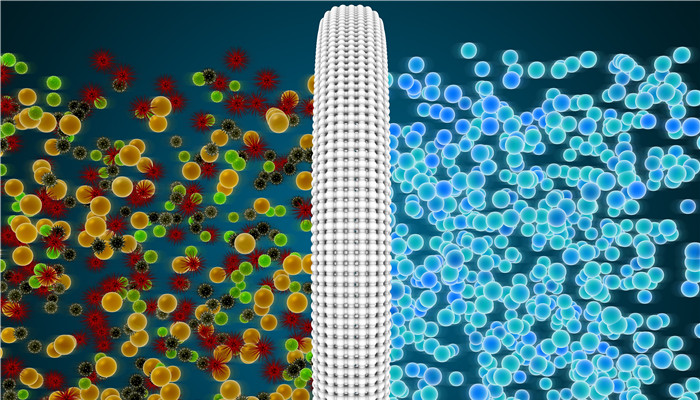

Radiation grafting technology can carry out radiation modification of materials. It can modify a variety of polymer materials such as styrene, acrylonitrile, acrylate, polyvinylidene fluoride, polyethersulfone, etc. It can also develop new materials. It is a radiation-based technology. One of the important directions of chemical research. Radiation grafted membrane is a membrane material prepared using radiation grafting technology. Compared with ordinary membrane materials, its physical, chemical, separation, filtration and other properties are better. It can be widely used in water treatment, battery separators, medical and other fields.

In the 1960s, radiation grafting technology has been used in industrial production. The radiation grafted membrane is a membrane material formed by using high-energy radiation to create active points in the polymer skeleton, and grafting another organic monomer to the active points to produce branched chains. According to the “In-depth Market Research and Investment Strategy Suggestions Report on Radiation Grafting Film Industry 2022-2026” released by the Industrial Research Center, Radiation grafting films can be prepared at room temperature or even low temperature. The preparation method is simpler than the chemical grafting method. It can be grafted on the surface or inside of the polymer without adding chemical additives, and irradiation can also be sterilized. The role of bacteria. Overall, radiation grafting films have obvious competitive advantages in terms of performance and process.

There are two preparation methods for radiation grafting films. One is to put the polymer skeleton and organic monomers together and irradiate them at the same time. The irradiation and grafting are performed simultaneously. It has the advantages of simple operation, high utilization rate of polymer free radicals, and easy polymer cleavage. However, the grafting efficiency is low and homopolymers will be generated; secondly, the polymer skeleton is irradiated first and then grafted with organic monomers, which has the advantages of no homopolymers and easy large-scale production. , has the advantage of high grafting efficiency, but the polymer free radical utilization rate is low.

Industry analysts said that in the field of water treatment, polyvinylidene fluoride membrane is an important separation membrane. Polyvinylidene fluoride is highly hydrophobic, and pollutants are easily deposited on the surface of the separation membrane, reducing its separation efficiency. Using radiation grafting technology, hydrophilic monomers and zwitterionic monomers are grafted onto polyvinylidene fluoride. The skeleton structure of the polyvinylidene fluoride film does not change significantly, but the hydrophilic performance is significantly improved, and the anti-fouling ability is greatly improved. improve.

In the field of battery separators, radiation grafting technology can be used to graft film materials and composite film materials to improve the performance of battery separators and thereby improve battery performance. For example, acrylic acid can be grafted on ultra-fine polyolefin fiber wet-laid non-woven fabric, and acrylic acid and sodium styrene sulfonate can be grafted on a double-layer composite membrane composed of ultra-fine polyolefin fiber wet-laid non-woven fabric and PP microporous film. , which can improve the charging performance and cycle life of the battery.

The radiation-grafted membrane can also be used as a medical filter membrane. For example, it can be used as a leukocyte-removing filter membrane, which can effectively filter out leukocytes in the blood and reduce the immune response to blood transfusion and the incidence of infection. In August 2020, the China Isotope and Radiation Industry Association released the group standard for “Radiation Grafting Leukocyte Removal Filtration Membrane”, which will be implemented in November 2020. The improvement of relevant standards will benefit the development of radiation grafting films in the medical field.

微信扫一扫打赏

微信扫一扫打赏