Activated carbon fiber has outstanding comprehensive advantages and its application fields are constantly expanding.

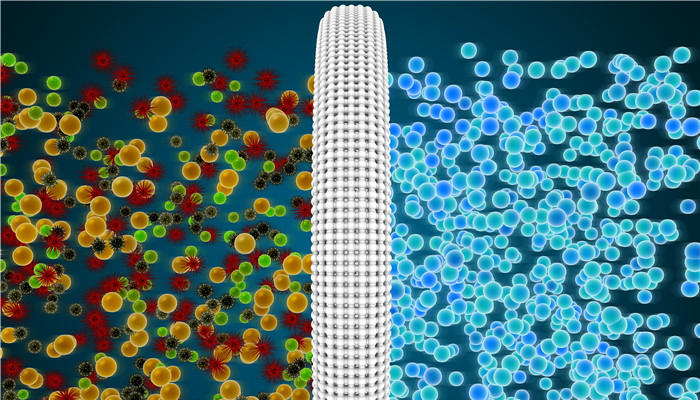

According to different shapes, activated carbon can be divided into powdered, granular, spherical and fibrous, among which activated carbon fiber (ACF) is the third generation of new adsorption materials after powdered activated carbon (PAC) and granular activated carbon (GAC). Activated carbon fiber is a porous carbon material prepared from organic fibers (such as phenolic-based fiber, polyacrylonitrile-based fiber, pitch-based fiber, polyvinyl alcohol-based fiber, etc.) through high-temperature carbonization and activation. It looks like a fibrous black solid, and the fiber Covered with micropores.

Due to its structural characteristics, the pore size of activated carbon fiber can reach the nanometer level. It has the advantages of large specific surface area, small and uniform pore size, fast adsorption speed, and strong adsorption capacity. Its organic gas adsorption capacity is several times that of granular activated carbon. With its good adsorption performance, activated carbon fiber is widely used in exhaust gas treatment, water purification, food, aerospace, personal protective equipment, catalyst carriers, functional electrode materials and other fields.

According to the “2022-2027 China Activated Carbon Fiber Industry Market In-depth Research and Development Prospects Forecast Report released by the Industrial Research Center, 2020 -In 2026, the total global activated carbon fiber market value will maintain a compound annual growth rate of 5.0%, and is expected to reach 3.8 billion yuan in 2026. Globally, the activated carbon fiber market is mainly concentrated in Europe, Asia-Pacific and North America, among which the demand for activated carbon fiber in the Asia-Pacific region is growing rapidly.

The activated carbon fiber industry started in the 1970s. With the advancement of related technologies, the types of activated carbon fiber products have gradually become richer. According to different pore sizes, activated carbon fibers can be divided into ultramicroporous (pore diameter 50nm). As a typical fibrous solid adsorption material, activated carbon fiber has various forms such as fiber mat, fiber cloth, fiber paper, fiber tow, fiber block, etc., which can meet different use needs.

In terms of production process, the activated carbon fiber preparation process mainly includes three stages: pretreatment, carbonization and activation. The activation process can be divided into physical activation method and chemical activation method. In terms of production companies, my country’s activated carbon fiber production companies include Anhui Jialiqi Advanced Composite Materials Technology Co., Ltd., Hainan Yeguo Activated Carbon Fiber Technology Co., Ltd., Jiangsu Kelite Environmental Protection Technology Co., Ltd., Jiangsu Tongkang Special Activated Carbon Fiber Fabric Co., Ltd., etc. .

Industry analysts said that activated carbon fiber is a third-generation new adsorption material. Compared with powdered activated carbon and granular activated carbon, activated carbon fiber has It has advantages in adsorption efficiency, pore size, specific surface area, etc. There are many types of activated carbon fibers with a wide range of applications. As market demand upgrades, the development of the activated carbon fiber industry will continue to upgrade toward diversification, high-end, and high efficiency, and there will be broad space for market development in the future.

微信扫一扫打赏

微信扫一扫打赏