Background and overview[1]

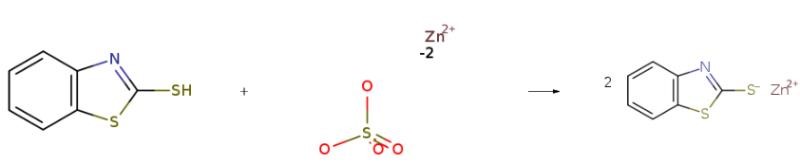

The accelerator zmbt is zinc 2-mercaptobenzothiazole. Mercaptothiazole metal compounds are often used as vulcanization accelerators for natural rubber, diene synthetic rubber and their latex. They can also be used as sulfur-containing stabilizers for asphalt. They are also used as agricultural fungicides and are used to prevent and control bacteria or diseases in crops. Play an important role in fungal diseases. Among them, 2-mercapto-5-amino-1,3,4-thiadiazole copper, 2-mercapto-5-amino-1,3,4-thiadiazole zinc, 2-mercaptobenzothiazole zinc (accelerator zmbt), bis(2-mercaptobenzothiazole) copper, etc. are the most representative.

Accelerator ZMBT can be used as an accelerator for natural rubber, general synthetic rubber and latex vulcanization. Its properties are similar to accelerator M, but its accelerating effect is slightly weaker. The critical temperature of vulcanization is relatively high, which is 138°C. It is not prone to early vulcanization problems, has a small tendency to scorch, and has a wide vulcanization flat zone. The vulcanized rubber prepared with the accelerator ZMBT has excellent aging properties and can improve the bonding strength between the rubber and the metal. The accelerator ZMBT is easily dispersed in water and does not pollute or discolor in the rubber compound. It is suitable for manufacturing latex products, rubber shoes, latex sponges, cables, medical and sanitary products, etc. It is also widely used as a heat stabilizer for fluoropolymers and nylon. For light stabilizers, heat-sensitive recording materials, etc., the general dosage is 0.5~1.5 parts.

Preparation[1]

In a 45mL ball mill reactor, place 8 chromium steel balls with a diameter of 2mm, and add 2-mercaptobenzothiazole (2.67g, 16mmol), zinc sulfate (1.61g, 10mmol), and water (1mL) in sequence. After the addition is complete, the reactor is sealed and placed in the ball mill at a rotation speed of 300 rpm for 5 minutes, with a cycle pause of 30 seconds. After four cycles, TLC trace indicated complete consumption of 2-mercaptobenzothiazole, and the reaction mixture was washed with water (5 mL×3). The filter cake was filtered and dried to obtain 3.17g of solid product accelerator zmbt, with a yield of 99.5%.

References

[1]CN201310754064.6 A ball milling synthesis method of mercaptothiazole metal compounds

[2] Song Kuijing. Application of optimization process of accelerator ZMBT [C]. Rubber Professional Committee of the Chinese Chemical Society, National Rubber Industry Information Center. “Comai Cup” 12th National Seminar on Rubber Additive Production and Application Technology Proceedings. Rubber Professional Committee of the Chinese Chemical Society, National Rubber Industry Information Center: Chinese Chemical Society, 2016: 121-122.

微信扫一扫打赏

微信扫一扫打赏