The application fields of fumed silica continue to expand and the market development prospects are good

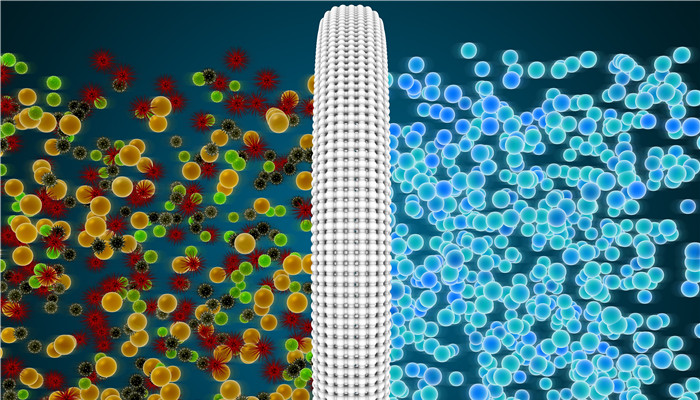

Fumed silica, also known as fumed silica and nanosilica, is an important new high-tech ultrafine inorganic material. Fumed silica is a white, fluffy, high-purity nano-inorganic non-metallic oxide. It is the nanomaterial with the largest production yield produced by the gas-phase method on a large scale. The main component of fumed silica is nano-silica, the SiO2 content is not less than 99.8%, and the primary particle size is between 7-80nm. According to the number of surface hydroxyl groups, fumed silica can be divided into two categories: hydrophilic and hydrophobic. Among them, hydrophobic fumed silica has excellent performance and a wider range of applications.

As an important functional powder material, fumed silica has the functions of thickening, thixotropy, extinction, and anti-precipitation. It also has the characteristics of small particle size, large specific surface area, excellent dispersion, and strong adsorption. With its With unique advantages, the application fields of fumed silica are increasingly expanding, involving many fields such as medicine, silicone rubber, food, catalysts, cosmetics, pesticides, inks and coatings, among which silicone rubber is its main application scenario. my country’s market demand for fumed silica is in a steady growth trend. Driven by this, the output of my country’s fumed silica industry continues to increase. In 2020, the industry’s output will be more than 144,000 tons.

According to the “China Fumed Silica Industry Market In-depth Assessment and 2022-2026 Investment Feasibility Consultation Report released by the Industrial Research Center It shows that with the expansion of application fields, the global market demand for fumed silica is growing steadily. However, due to the complex production process and high technical barriers of fumed silica, the production capacity of fumed silica is relatively concentrated. Among them, Evonik Degussa, German Watts Companies such as Gram Chemical, Japan Tokuyama Chemical, Cabot, and Japan Toyo have a relatively high market share. Overall, Germany, the United States, and Japan are the world’s major producers of fumed silica, and have long occupied a major share of the market.

In the domestic market, the main suppliers of fumed silica include Yichang Huifu Silicon Materials, Guangzhou Jibisheng, Jiangxi Hongbai New Materials, Hesheng Silicon Industry and other local companies, as well as Jiangxi Cabot Blue Star Chemical, Yingxinan (Zhenjiang) Silicon Materials, Cabot Hengye (Inner Mongolia) and other joint ventures. The fumed silica project is a national strategic emerging industry project. Driven by policy support, corporate assistance, and technological empowerment, my country’s fumed silica industry has developed rapidly, and my country has gradually become one of the main driving forces for the growth of the global fumed silica industry. one.

Industry analysts said that as a new ultrafine inorganic material, fumed silica has thickening, thixotropic, matting, and anti-precipitation properties. and other functions, the downstream application fields are extensive and are constantly expanding, and the fumed silica market has broad development space. For a long time, Germany, the United States, and Japan have occupied the major shares of the global fumed silica market. In recent years, with the advancement of technology in my country and the increase in the number of companies entering the market, the production capacity of fumed silica has been continuously improved, and the localization rate of products has grown steadily.

微信扫一扫打赏

微信扫一扫打赏