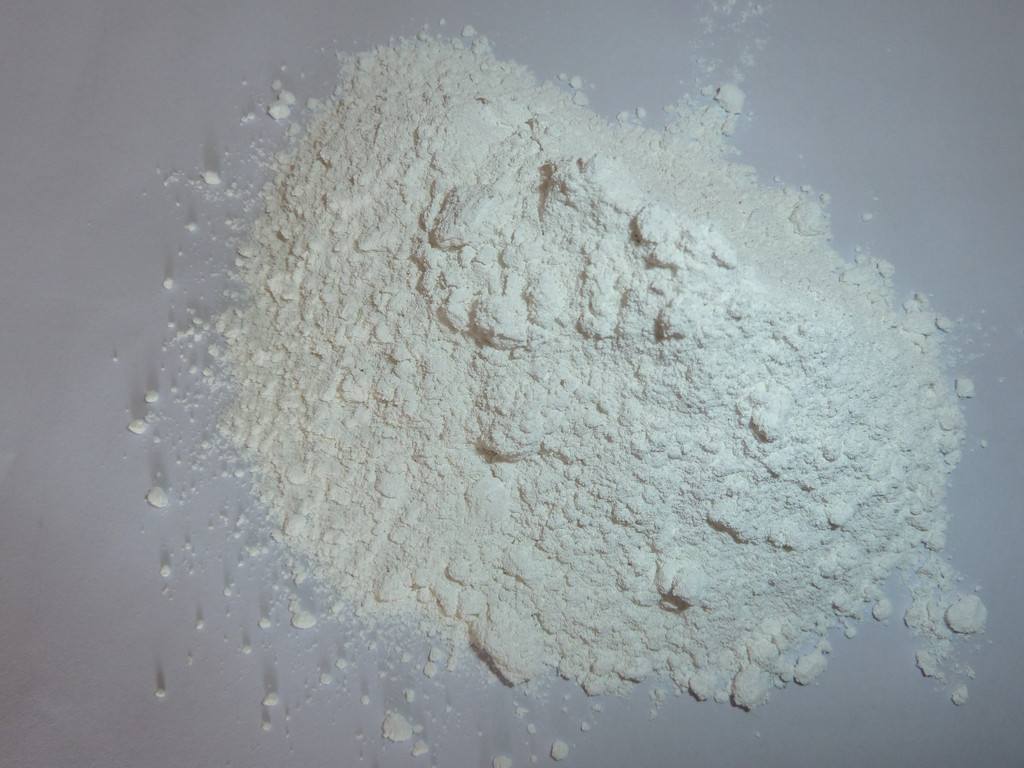

Calcium carbonate is a white inorganic compound that is widely used in industry. Calcium carbonate is the most commonly used inorganic filler in rubber. Its main function is to increase the volume of rubber and reduce costs. It can also improve the processing performance of rubber and improve the performance of products. Calcium carbonates commonly used in the rubber industry include heavy calcium carbonate, light calcium carbonate, activated calcium carbonate, and nano-calcium carbonate. Today I would like to share with you the characteristics of four types of calcium carbonate.

1. Heavy calcium carbonate: heavy calcium for short, is a powdery inorganic filler obtained by mechanically crushing natural carbonate minerals. It has the characteristics of stable chemical properties, good thermal stability, no decomposition at room temperature, low hardness, low wear value, and high inertness. As a filler in rubber, it has no reinforcing effect and is cheap. It can also be used as an isolation agent, desiccant, and release agent.

2. Light calcium carbonate: Light calcium for short, also known as precipitated calcium carbonate, is made from limestone as raw material and processed by chemical methods. It is a white powder or colorless crystal with the characteristics of non-toxic, odorless, non-irritating, small particle size and regular particle shape. It is often used as reinforcing filler in rubber and has a semi-reinforcing effect. It is widely used in natural rubber, synthetic rubber and reclaimed rubber HY13S10J2Y-WFM.

3. Activated calcium carbonate: It is based on ordinary calcium carbonate, added with additives, and modified and activated. It is a white powdery substance that is non-toxic, odorless, non-irritating, easy to color and insoluble in water. It has the characteristics of good fluidity, uniform dispersion, large filling amount, small particle size and high whiteness. It has good compatibility in rubber, making the rubber easy to mix and disperse. It plays a reinforcing and filling role in the rubber compound and has a color-adjusting effect. It can be applied to various reclaimed rubber products.

4. Nano calcium carbonate: Also known as ultrafine calcium carbonate, it is a functional inorganic filler made from limestone and using new technologies. It is odorless, insoluble in water and ethanol, and has small particles. It plays a reinforcing and filling role in rubber and also has a whitening effect. It can partially replace expensive white fillers such as silica black and titanium dioxide. Commonly used as reinforcing filler and whitening agent.

Calcium carbonate is widely used in rubber products. It is a commonly used compounding agent and has different functions in different products. The selection should be based on each type of calcium carbonate. Reasonable selection of characteristics and reasonable design of usage can effectively reduce production costs.

微信扫一扫打赏

微信扫一扫打赏