● BASF provides innovative products and technologies to various industries

● TripleS (Sustainable Solutions Guidance) transparently assesses the sustainability of the product portfolio

● Sales of products developed and marketed within the last five years increased to approximately €12 billion in 2022

At a recent R&D press conference, Dr. Melanie, Member of the Executive Board and Chief Technology Officer of BASF Group

Maas-Brunner said: “Chemistry and sustainable development complement each other, and BASF has long understood. As the world’s leading chemical company, we provide innovative solutions and make important contributions to the sustainable development transformation of society and the efficient use of limited resources.” Dr. Ma Lanli and BASF technical experts focused on current innovative projects at the meeting and explained specific examples of sustainable development in detail.

BASF is constantly developing new products and technologies that are more sustainable. Dr. Ma Lanli said: “This is due to BASF’s unique innovation strength, and multiple data indicators have fully proved this.” In recent years, sales of new products developed by BASF have continued to grow, both from research and development and in the past

Sales of products on the market in 5 years increase to €12 billion in 2022. In addition, 1,000 submitted last year

Multiple patent applications also fully prove BASF’s innovative strength and help BASF maintain its industry leadership. Dr. Ma Lanli said: “I am very pleased that 40% of these patents relate to sustainable development, and another 20%

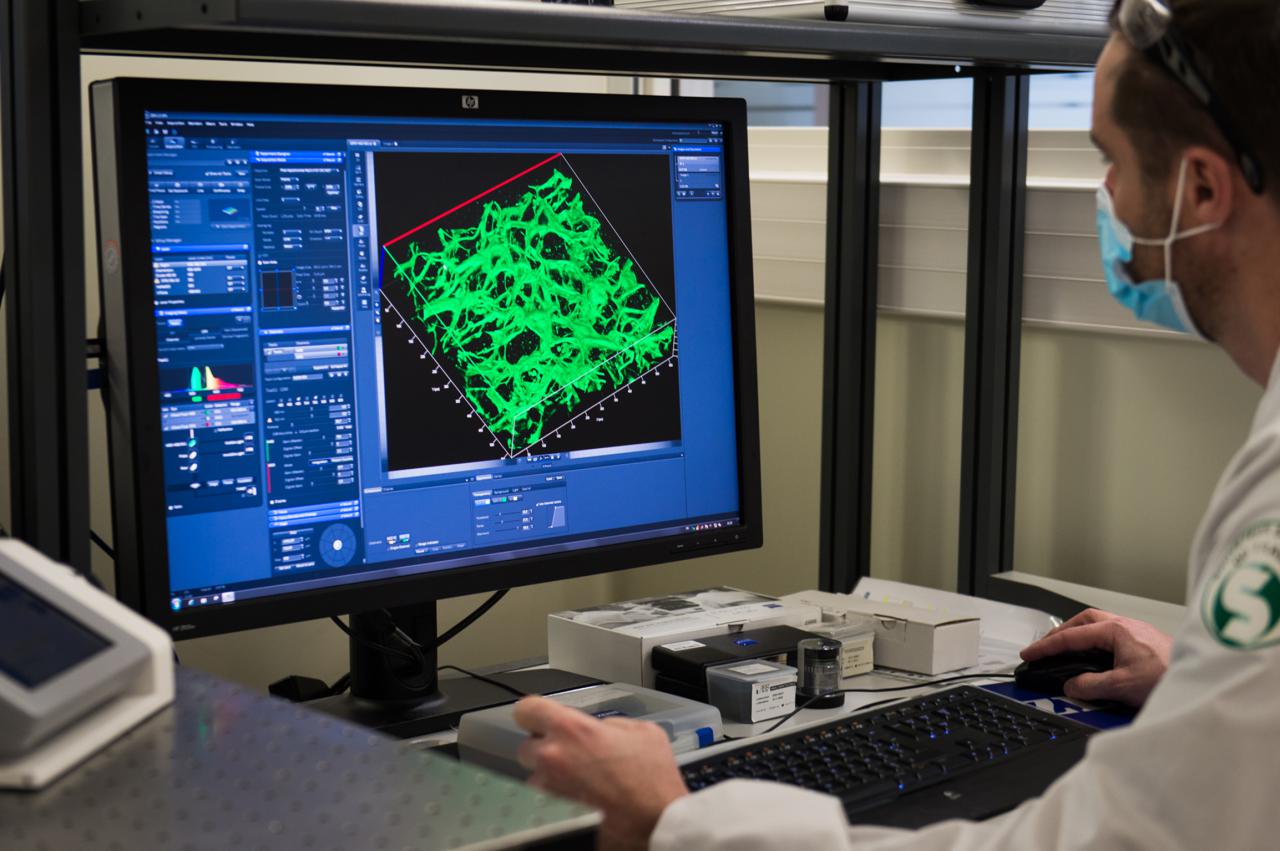

related to digitalization. “BASF’s approximately 10,000 R&D employees worldwide contribute to the company’s above-mentioned success. “As chief technology officer, I am proud of this high-quality R&D team. Dr. Ma Lanli detailed a current research project aimed at developing materials that can significantly improve the efficiency of water electrolysis. Water electrolysis is used to produce zero-carbon emission hydrogen and is critical to the transformation of the chemical industry.

Increase sustainability transparency

To help customers better achieve sustainable development, BASF jointly launched the internationally recognized TripleS

approach (i.e. Sustainable Solutions Guidance) to continuously and consistently evaluate its product portfolio. BASF uses this method to evaluate the sustainable contribution of existing products and divides them into five categories: pioneering, promoting, standard, monitoring and challenging. For products with major sustainability deficiencies (challenged), BASF will

phase it out within 5 years. To align its product portfolio even more with the requirements of climate protection, resource efficiency and circular economy, BASF launches updated TripleS in 2023

method. The sales proportion of the above five categories of products will be specified in the “BASF Group 2023 Performance Report”, which is expected to be released on February 23, 2024.

Released on the same day. BASF will set new targets for the sales share of the first two product categories (pioneer and promoter). Dr. Ma Lanli said: “With the help of

TripleS, we can clearly assess the performance and improvement of our business activities in terms of sustainability. ”

BASF experts used five innovative products and technologies as examples to show customers from all walks of life how to better achieve sustainable development goals.

Laying durable roads

Increasing heavy-haul traffic and more extreme weather conditions are wearing down the world’s roads, with asphalt pavements typically requiring replacement every 10 to 12 years. To this end, BASF launches an innovative asphalt additive

B2Last® (Bitumen to Last) can reduce the carbon footprint during construction while increasing the service life of roads.

The additive is based on an isocyanate system that cross-links the individual components of asphalt into a polymer network, thereby improving the resilience of the asphalt and giving the road better durability and rutting resistance in both high and low temperature environments. Extensive tests carried out by BASF together with academic partners have confirmed this. Using this new additive, pavements can be paved in lower temperature environments, and the organic pollutants released from asphalt during construction will be reduced.

65%. The additive also helps reduce CO2 emissions, as roads are paved less often and less energy is required for the asphalt production and paving process. Additionally, using B2Last

The proportion of recycled bitumen (recycled bitumen) in an asphalt mix can be increased, thereby reducing the total energy, resources and CO2 emissions associated with producing new asphalt mixes.

Reduce resistance and assist flight

By reducing the frictional resistance of an aircraft in the air, its fuel consumption and carbon dioxide emissions will also be reduced. Since the 1980s

For decades, researchers have been looking for solutions to reduce air drag. Nature can always give birth to inspiration. Take shark skin as an example. The fine stripes on the surface can reduce the resistance generated by the shark when swimming in the water. Now, researchers at BASF and Lufthansa Technik have achieved a breakthrough and developed

NovaFlex SharkSkin membrane. The functional film reduces air resistance, resists UV rays, and withstands rapidly changing temperature differences and mechanical stresses.��.

The innovative 50-micron-high striped film is being used on Lufthansa Cargo’s entire 777F cargo fleet and all of SWISS’s Boeing 777-300ER passenger aircraft. Posted on moving parts of the aircraft

NovaFlex SharkSkin film can reduce air resistance by 1.1%. Each aircraft (taking the Boeing 777-300ER passenger aircraft as an example) can reduce approximately 400 tons of fuel per year, reducing approximately

1,250 tons of CO2 emissions. In the future, more NovaFlex SharkSkin films will be posted on the fuselage to reduce 3%

air resistance. In addition, BASF is further developing functional films for use in other industrial fields, such as wind turbine blades to improve power generation efficiency and ship hulls to reduce fuel consumption.

Inject vitality

Skin is the largest organ of the human body, and various bacteria live on its surface. They are very important for maintaining skin health. To this day, the exact role of these bacteria remains poorly understood. A study conducted by BASF researchers showed that young people have high levels of Lactobacillus crispatus in the skin around their eyes, but this bacterium is not found in the wrinkles of older people. In vitro experiments show that these live bacteria can stimulate skin cells to produce collagen.

Based on these findings, BASF developed Probiolift®

, the first cosmetic active ingredient containing Lactobacillus crispatus, a live probiotic found on human skin. In a randomized, double-blind clinical study, the active ingredient was shown to significantly increase skin density and reduce forehead wrinkles in volunteers. Probiolift®

Produced using a special fermentation process that is extremely energy-saving. Even more sustainably, BASF also uses the fermentation supernatant to produce a second active ingredient

Postbiolift®. It contains metabolites of Lactobacillus crispatus that help improve skin elasticity and reduce wrinkles around the eyes.

Precise crop protection

Weeds in farm fields can reduce crop yields by 30% or more. To control weeds, farmers typically spray herbicides at standard doses over the entire field. BASF-Bosch joint venture develops ONE SMART

SPRAY solution for more precise, long-lasting weed control.

ONE SMART SPRAY

It is an innovative solution integrating software and hardware that uses BASF’s agronomic platform xarvio® to automatically identify and treat weeds in field crops in real time. During development, the product research team created additional dedicated software modules with unique weed detection threshold logic, including weeding recommendations. Bosch uses high-tech cameras, sensors and algorithms to optimize crop and weed identification technology. This provides farmers with a customized herbicide application strategy, helping them to know the best application timing, product and dosage.

BASF and Bosch have been testing ONE SMART SPRAY with farmers in North, South America and Europe over the past few years.

, thereby developing more accurate tools. During the cultivation of soybeans, sunflowers, cotton, corn and rapeseed, it can control more than 650 types of weeds, ensuring crop yields and protecting the ecological environment. For use in the field with ONE

SMART SPRAY’s crop sprayers have 100 sprays per hectare.

Thousands of data points are collected and processed. The technology can detect weeds in a field within milliseconds and spray herbicides precisely where needed. Save 2/3 depending on growing conditions and weed pressure

or more herbicide rates.

Pushing battery materials into the future

Electric vehicles using green electricity do not emit any exhaust gas during driving, but the production of cathode active materials (CAM) required for electric vehicles and their batteries consumes a lot of resources. To this end, BASF is committed to significantly reducing the environmental impact of battery materials throughout the entire value chain, focusing on three aspects: the cathode active material itself and its production process, as well as recycling battery materials from end-of-life batteries.

Innovative cathode active materials are a key determinant of the performance, safety and cost of modern lithium-ion batteries for electric vehicles. During the development process, BASF has a variety of methods that decisively influence the performance of battery materials. These include the material composition, various particle sizes and distributions, as well as the adjustment of porosity and surface properties to meet the individual needs of customers.

BASF researchers also use advanced processes to produce cathode active materials, reducing the use of expensive materials such as nickel and cobalt without affecting battery performance. In addition, BASF continues to increase energy and resource consumption in each process and switches to renewable energy.

An important way to make battery materials more sustainable is to increase the use of recycled metals such as lithium, nickel, cobalt, and manganese. Improving the yield of the above-mentioned metals in the recycling process while reducing the use of chemicals is another focus area of BASF’s battery materials research.

微信扫一扫打赏

微信扫一扫打赏