Background and overview[1]

O-chlorobenzoic acid is an important intermediate with a wide range of uses in the pesticide, pharmaceutical and dye industries. In the o-chlorobenzoic acid synthesis process, there are four main production methods: diazotization, oxidation, chlorination, and bionic catalytic oxidation. The reaction conditions of the diazotization method are relatively mild, but the process route is long, the cost is high, and there are more three wastes. The characteristic of the oxidation process is that o-chlorotoluene is directly oxidized under catalytic conditions to produce o-chlorobenzoic acid. The post-processing of products produced by this method is more cumbersome and the production cycle is longer. The chlorination method is currently commonly used by manufacturers, but the reaction time is long, there is a lot of waste gas and waste water, and the yield is low, so it is not suitable for industrial production. The green synthesis of o-chlorobenzoic acid through biomimetic catalytic oxidation will be a promising method. As an important fine organic chemical product, o-chlorobenzoic acid has broad market prospects. How to combine my country’s actual situation to develop a short process, easy to control reaction conditions, high yield, low cost, and environmentally friendly o-chlorobenzoic acid synthesis route is imperative.

Apply[2-3]

O-chlorobenzoic acid is an important intermediate with a wide range of uses in the pesticide, pharmaceutical and dye industries. In pesticides, it is mainly used to synthesize insecticides (Threonil No. 1) and antifungal agents. In medicine, it is mainly used to synthesize the antipsychotic drug perphenazine, the adrenomimetic drugs Zengrubenzin and Chuantong, and the antifungal drug Gram Drugs such as triazole, chlorpromazine, ketamine and diclofenac are standard reagents for alkali and iodometric methods. They are used as preservatives for adhesives and paints. They can also be used in raw materials for organic synthesis, dyes and color films. Their market prospects It is relatively broad [1, 2]. As an important fine organic chemical product, o-chlorobenzoic acid has been extensively studied in recent years. Examples of its application are as follows:

1) Prepare mefenamic acid, using o-chlorobenzoic acid as raw material, in the presence of an acid-binding agent, using an aprotic polar solvent to form a salt to obtain o-chlorobenzoate; under the action of a dehydrating agent, Metal manganese powder or manganese salt is used as a catalyst, o-chlorobenzoate and 2,3-dimethylaniline undergo a condensation reaction, and then are acidified to obtain mefenamic acid. The invention provides a synthesis method of mefenamic acid, which has the advantages of high reaction yield, high product quality and low production cost, and solves the problems of low product yield and dark product color existing in the existing preparation methods. question.

2) Preparation of the photoinitiator 2-isopropylthioxanthone, specifically a photoinitiator using p-isopropylthiophenol and o-chlorobenzoic acid as the main raw materials, through condensation, desolvation, neutralization, and cyclization. A process for preparing 2-isopropylthiaxanthone through reaction steps such as fusion, hydrolysis, and recrystallization. It is characterized in that p-isopropylthiophenol and o-chlorobenzoic acid are used as raw materials, and tetralin is used as a solvent for condensation under alkaline (lithium hydroxide) conditions. p-isopropylthiophenol: o-chlorobenzoic acid : The molar ratio of lithium hydroxide is 1:1~1.5:2~2.5, preferably 1:1.05:2.1; the condensation temperature is 180-190°C, and after 6 hours of reaction, it undergoes desolvation, neutralization, cyclization, hydrolysis, The product is prepared through reaction steps such as recrystallization. The invention has the advantages that raw materials are easily available and can improve the executability of the process. Moreover, the generated by-product lithium chloride can be processed and sold, which can greatly reduce the production cost. At the same time, the produced product has high purity and no isomers.

Preparation[1]

There are many synthesis routes for o-chlorobenzoic acid, including diazotization, oxidation, chloride hydrolysis, biomimetic catalytic oxidation and other synthesis methods.

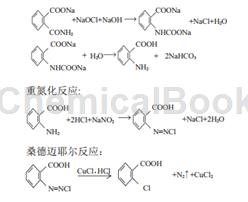

1. Diazotization degradation reaction:

The diazotization method uses phthalic anhydride as raw material. First, it undergoes amidation reaction with NaOH and NH4OH to generate sodium o-carboxamido benzoate. After NaOCl degradation reaction, sodium anthranilate is generated, which is neutralized and refined to obtain o-aminobenzoate. Benzoic acid is then subjected to a diazotization reaction with Na2SO3 and HCl. Under the catalysis of cuprous salt, the diazo group of the obtained diazonium salt is replaced with a chlorine group and a Sandmeyer transformation reaction occurs to obtain a crude o-chlorobenzoic acid product. After refining, the finished product is obtained [3]. In order to reduce costs, some manufacturers directly diazotize anthranilic acid. However, anthranilic acid is a by-product of the production of saccharin sodium. Currently, there are few sources. The shortage of raw materials limits industrial production. The advantage of this method is that the reaction conditions are mild, but its disadvantages are that the process route is long, the cost is high, the equipment is severely corroded, the waste water and waste gas are generated, and the environment is seriously polluted, so it has been gradually eliminated.

2. Oxidation method Oxidation method

Using o-chlorotoluene as raw material, o-chlorobenzoic acid is prepared by oxidation method. According to different oxidants, it can be divided into chemical reagent oxidation method and air oxidation method.

1) Chemical reagent oxidation method: Chemical reagents are used as oxidants. Commonly used chemical oxidants include heavy NaCr2O4, KMnO4 and NHO3. Since the NaCr2O4 oxidation method needs to be carried out in H2SO4 aqueous solution, the equipment is severely corroded and there is recycling of heavy metals. and pollution, etc., making it unsuitable for industrial production. NHO3 is widely used in industry. Oxidation with KMnO4 needs to be carried out in a large amount of water. Since o-chlorotoluene is insoluble in water, the reaction is a two-phase reaction, so it is not easy to carry out completely and the yield is low.

2) Air oxidation method

The air oxidation method refers to using air as the oxidant, cobalt, manganese, etc. as the catalyst, and low-gradeAliphatic carboxylic acid is used as a solvent and is oxidized in the next step of pressure. The disadvantages of this process are serious environmental pollution and poor labor hygiene conditions. In addition, the production cost of the process using carboxylic acid as the solvent is high, the mother liquor cannot be directly recycled, the recycling treatment is troublesome, and the equipment is severely corroded. The liquid phase catalytic air oxidation catalyst uses a catalyst and can oxidize o-chlorotoluene with air to synthesize o-chlorobenzoic acid without using a solvent. The advantages of this method are that the reaction conditions are mild, the mother liquor can be recycled, and the environmental pollution and equipment corrosion are small. It is a green production process and has been put into production in China. Compared with the diazotization method, the liquid phase oxidation method has the advantages of short process route, less waste gas and waste water, and low cost. The disadvantages are that the production cycle is long and the post-processing of the product is cumbersome. At present, most of the research and development of this process is in the screening and optimization stage of catalysts and reaction conditions.

3. Chloride hydrolysis method

The chlorination method uses o-chlorotoluene as raw material. First, o-chlorotrichlorotoluene is obtained by passing Cl2 in the presence of PCl3 catalyst, and then hydrolyzes it into o-chlorobenzoic acid. Compared with the diazotization method and the oxidation method, the catalytic photochlorination method has many advantages such as short process flow, easy control of reaction conditions, high yield, low cost, and low environmental pollution.

4. Biomimetic catalytic oxidation

Bionic catalysis is an unconventional catalytic technology that is different from traditional chemical catalysis and biological catalysis. It is based on the catalytic principle of enzymes in living organisms. By using macrocyclic compounds to simulate certain active groups or parts of biological catalysts, chemical catalysts with certain functions of biological catalysts are designed and synthesized under specific conditions of the dosage of biological enzymes. Simulating the catalytic process of enzymes, by replacing the conventional heterogeneous catalytic reaction system with a simple homogeneous reaction system, it is possible to catalyze oxygen to selectively catalyze saturated hydrocarbons with high activity and selectivity under mild conditions to functionalize them. Clean chemical production technology. Use metal porphyrin bionic catalysts to replace conventional catalysts, use clean and cheap O2 to replace chemical oxidants with serious environmental pollution, use alkaline media to replace acidic media with severe equipment corrosion, and develop a method that can catalyze the oxygen liquid phase under mild conditions. A new method for green synthesis of chlorobenzoic acid by oxidizing chlorotoluene has made some progress.

Main reference materials

[1] Research progress on the synthesis of o-chlorobenzoic acid

[2] CN201610475862.9 A synthesis method of mefenamic acid

[3] Preparation process of CN200810025425.22-isopropyl thioxanthone

微信扫一扫打赏

微信扫一扫打赏