Consumers have long been concerned about the safety and environmental protection of coatings, and environmental regulations have become increasingly strict. High-efficiency defoaming agents with low VOC content and meeting environmental label requirements have been the focus of the architectural coatings industry. In response to market demand, Evonik’s coating additives business line launched TEGO®, a high-efficiency polyethersiloxane emulsion defoamer used in architectural coatings that complies with environmental labels and has VOC and SVOC as low as 0.01%.

Foamex 11.

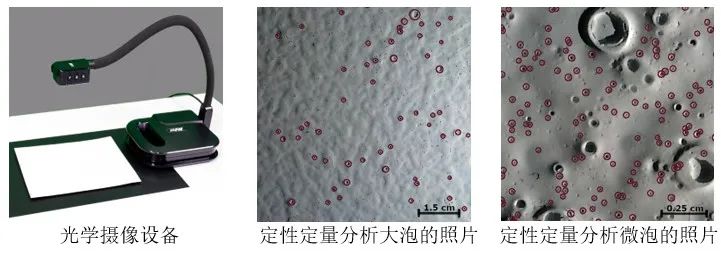

COATINO® Defect Detection Image Analysis System

In the process of developing defoaming agents that meet market development needs, scientists from Evonik’s coating additives business line specially developed COATINO® in order to conduct more in-depth and accurate analysis and research on the performance of defoaming agents in coating applications.

Defect

Detection paint film image analysis system, which can conduct optical analysis of the paint film surface and qualitatively and quantitatively identify macrobubbles, microbubbles and compatibility. With the help of this advanced equipment, TEGO® with low VOC content, balanced high defoaming efficiency and compatibility was developed.

Foamex 11 defoamer.

TEGO® Foamex 11 efficient defoaming performance

Comparison of TEGO® Foamex in three different PVC formulas: medium, medium and low (30%, 53% and 76%)

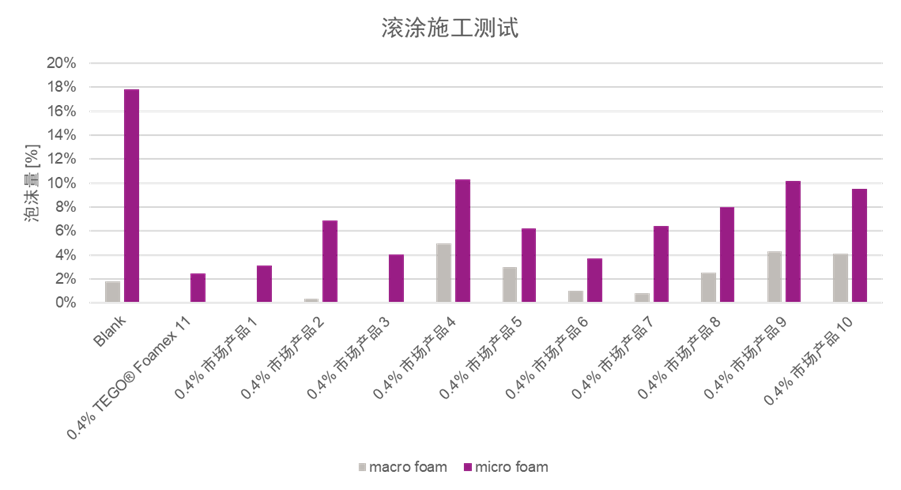

11 Perform performance evaluation, conduct comparative testing with 10 common defoaming agents based on mineral oil on the market, and use a porous roller for roll coating construction testing. Porous drum construction will produce a large number of bubbles, including a large amount of microbubbles that are difficult to eliminate.

Porous roller👇

After the paint film is dry, COATINO® Defect Detection is used to conduct optical analysis of the paint film to analyze surface defects of the paint film, qualitative and quantitative analysis of macrobubbles and microbubbles, and analyze compatibility.

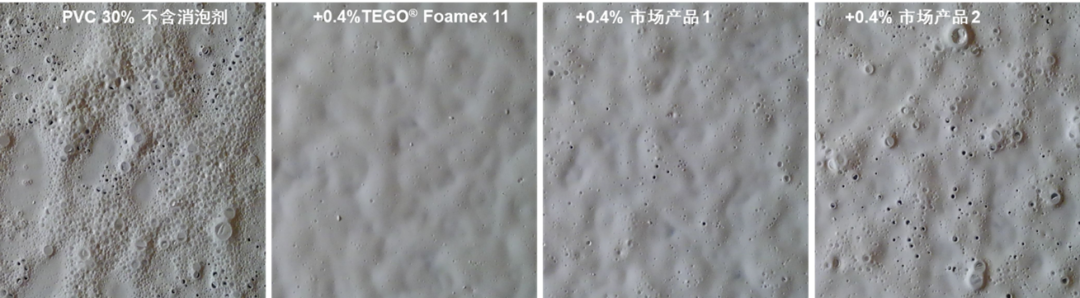

Paint film of PVC 30% coating

Low-PVC formula coatings, especially low-VOC and sensitive coating products, in addition to common macrobubbles, a large number of microbubbles are usually a huge challenge faced by this type of coatings. Defoaming agents are required to eliminate macrobubbles and microbubbles. Both compatibility and VOC content have very high requirements.

Qualitative and quantitative analysis of macrobubbles and microbubbles in paint films through COATINO® Defect Detection, TEGO® Foamex 11

Has the highest efficiency in eliminating macrobubbles and microbubbles.

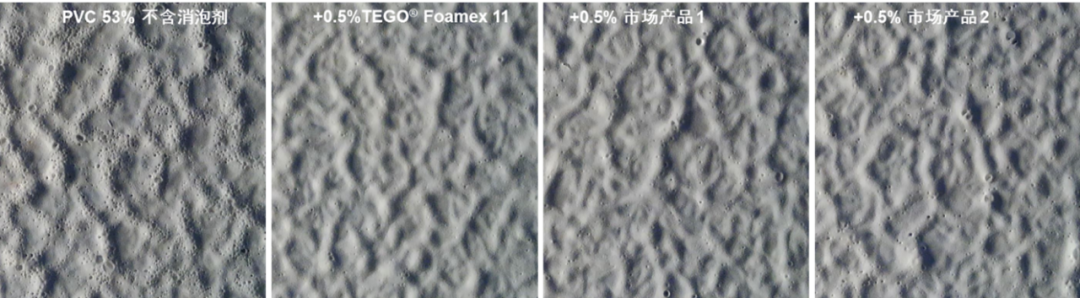

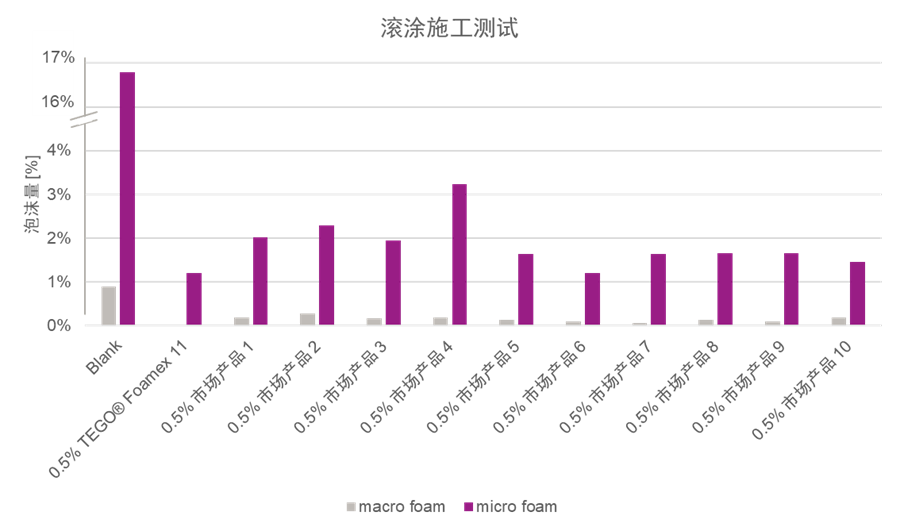

PVC 53% paint film

For medium PVC coatings, especially coatings with strong thixotropy, the defoaming speed, especially the speed of eliminating microbubbles, is particularly important. TEGO® Foamex

11Quickly eliminate large and microbubbles to bring a perfect paint film without incompatibility.

Qualitative and quantitative analysis of macrobubbles and microbubbles in paint films through COATINO® Defect Detection, TEGO® Foamex 11

Shows the highest defoaming efficiency, especially the elimination of microbubbles.

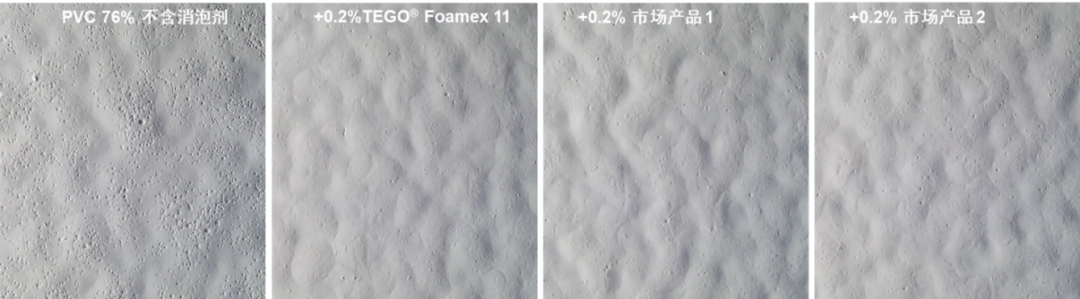

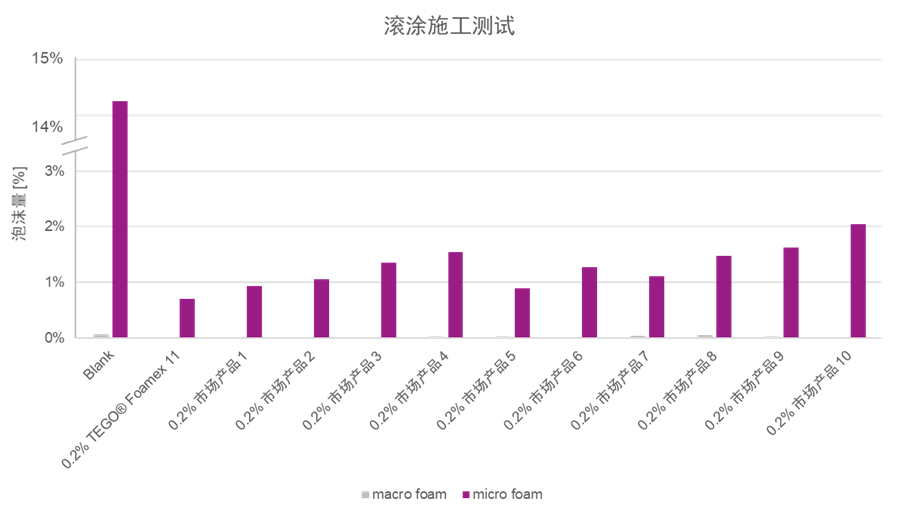

PVC 76% paint film

In high PVC formulas, TEGO® Foamex 11 only requires a lower addition amount to achieve perfect defoaming effect, efficient defoaming and reduced costs.

From the above comparative test results of three different PVC coatings, we can see that only TEGO® Foamex 11 can effectively eliminate bubbles in the paint film, especially microbubbles in sensitive and highly thixotropic coating formulations.

Conclusion

TEGO® Foamex

11 is a defoaming agent suitable for environmental labeling, with VOC and SVOC content as low as 0.01%, complying with increasingly stringent regulatory requirements. In addition to its environmental protection performance, this defoaming agent effectively balances high defoaming efficiency and compatibility, quickly eliminating bubbles in the paint film without causing surface defects in the paint film, and is especially suitable for use in paints with low VOC and sensitive formulas.

微信扫一扫打赏

微信扫一扫打赏