Background and overview[1]

Sulfone compounds are a class of organic compounds with wide applications. The sulfonyl groups they contain are widely found in various chemical substances such as pharmaceuticals, agricultural chemicals, and functional materials. Selective oxidation using thioethers is one of the most common methods for the synthesis of sulfones. Benzyl phenyl sulfone can be used as a pharmaceutical synthesis intermediate. In the existing research on the selective oxidation of thioethers into sulfone compounds, acids, metal oxides, organic peroxides, inorganic peroxides, halogens, etc. are commonly used as oxidants. The dosage of these oxidants is generally excessive, and there are It has shortcomings such as being difficult to control and difficult to separate. Oxygen, as the most ideal oxidant, has always been a hot research topic. However, there are still many problems in the study of oxygen as an oxidant to catalyze the selective oxidation of thioethers to sulfone compounds, such as adding a large amount of aldehydes as sacrificial agents, complex catalyst synthesis, and high cost. High, narrow application range, etc.

Preparation[1]

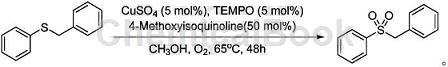

Benzyl phenyl sulfone is prepared as follows:

The specific steps are as follows: TEMPO (3.9 mg, 0.025 mmol), methanol (1 mL), CuSO (4.0 mg, 0.025 mmol), 3,5-lutidine (28.2 μL, 0.25 mmol) were added to a 100 mL Schlenk reaction tube. ), anisole sulfide (58.8 μL, 0.5 mmol), filled with 1 atm of oxygen, sealed reaction tube heated to 65°C and reacted for 72 hours. After the reaction is completed, cool to room temperature, add an appropriate amount of ethyl acetate, a blue solid precipitates in the reaction solution, filter, and the filtrate is concentrated under reduced pressure, and separated and purified by column chromatography to obtain the product with a yield of 82%.

The product is represented by:

HNMR (500MHz, CDCl): δ7.95 (d, J=8.1Hz, 2H), 7.69-7.66 (m, 1H), 7.60-7.57 (m, 2H), 3.06 (s, 3H).

CNMR (125MHz, CDCl): δ140.6, 133.7, 129.4, 127.3, 44.5.

Preparation method By screening a large number of ligands, the oxidation ability of the catalytic system is greatly improved, so that the target product aryl sulfone compound can be obtained in high yield. At the same time, the metallic copper in the catalytic system can be recycled through extraction after the reaction, and the recycled product has good reactivity, which greatly reduces the preparation cost.

Main reference materials

[1] CN201811104682.5 Preparation method of aryl sulfone compound and extraction method of catalyst and aryl sulfone compound

微信扫一扫打赏

微信扫一扫打赏