Background and overview[1]

Phenylhydrazine oxalate is the salt form of phenylhydrazine. Phenylhydrazine salts and substituted phenylhydrazine salts (such as p-chlorophenylhydrazine hydrochloride, etc.) are important pharmaceutical and pesticide intermediates.

Preparation[1]

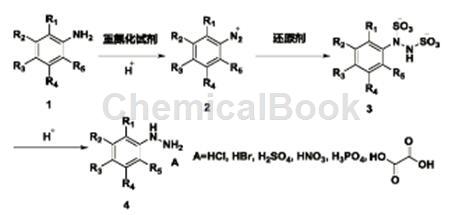

The present invention provides a continuous flow synthesis process of phenylhydrazine oxalate, which uses aniline or substituted aniline acidic liquid, diazotization reagent, reducing agent and acid as raw materials, and continuously and sequentially undergoes diazotization, reduction and acidolysis to form a salt. After a three-step reaction, phenylhydrazine oxalate is obtained. The reaction route is as follows:

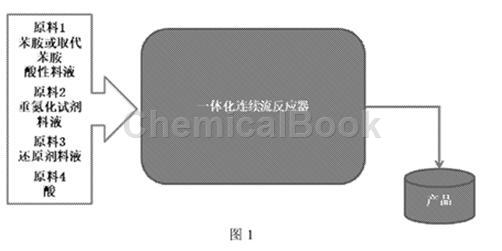

Figure 1 is a process diagram of the continuous synthesis method.

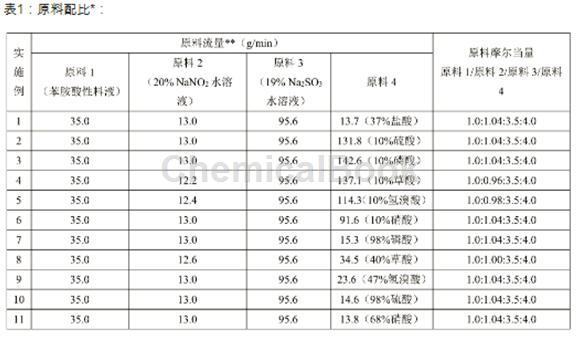

As shown in Figure 1, raw material 1 (aniline acidic liquid) and raw material 2 (NaNO2 aqueous solution with a concentration of 20%) are transported into the temperature zone 1 with a constant flow pump and flow through the temperature zone 1 to complete the diazotization reaction. . Use a constant flow pump to transport raw material 3 (Na2SO3 aqueous solution with a concentration of 19%) to temperature zone 2 for preheating, then mix it with the diazonium salt generated in temperature zone 1 in temperature zone 3, and then flow through temperature zone 3 until reaction Complete, the reaction liquid flowing out of temperature zone 3 is mixed with raw material 4 (acid) and then enters temperature zone 4, flowing through temperature zone 4 until the reaction is complete. The reaction mixture was collected, cooled and crystallized. After filtering and drying, the product phenylhydrazine oxalate can be obtained. The reaction parameters and results are as follows:

WO2018019250 provides a new continuous-flow synthesis process for phenylhydrazine oxalate (continuous-flow process), which organically integrates the three-step reactions of diazotization, reduction and acidolysis into salts to form aniline or Substituted aniline acidic liquid, diazotizing reagent, reducing agent and acid are used as raw materials, and the three-step reactions of diazotization, reduction and acidolysis to form salts are carried out successively to obtain phenylhydrazine salts and substituted phenylhydrazine salts. The synthesis process is as follows It is carried out in an integrated reactor. It is an integrated solution. For the first time, the three-step reaction of diazotization, reduction and acidolysis to salt is realized in a single reactor, which greatly shortens the reaction time and improves the efficiency of the reaction. improve reaction efficiency and product quality. That is, the reaction raw materials (aniline or substituted aniline acidic liquid, diazotization reagent, reducing agent and acid) are continuously added to the feed port of the integrated reactor, and diazotization is carried out continuously and sequentially in the integrated reactor. ionization, reduction and acidolysis to form salts, and phenylhydrazine salts and substituted phenylhydrazine salts are continuously obtained at the outlet of the integrated reactor, and the total reaction time is ≤20 min. Compared with the traditional production process, the total reaction time is greatly shortened and the safety is greatly improved. Moreover, the reaction process of the synthesis process does not contain diazoamino compounds, and the product at the outlet does not contain diazoamino compounds and reduction reactions. Intermediates and reduction reaction products.

Main reference materials

[1] 2. (WO2018019250) A continuous flow synthesis process of phenylhydrazine salts and substituted phenylhydrazine salts

微信扫一扫打赏

微信扫一扫打赏