Background and overview[1]

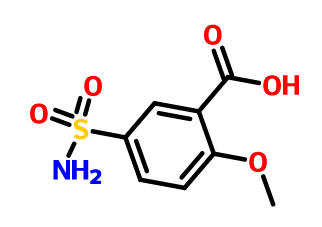

5-Sulfamoyl-2-methoxybenzoic acid, also called 2-methoxy-5-sulfamoylbenzoic acid, is the intermediate of Sulpiride. Sulpiride is an antipsychotic drug. Indications: It has a good effect on the symptoms of apathy, withdrawal, stupor, depression, hallucinations and delusions. It is suitable for the symptoms of isolation, withdrawal and apathy in simple, paranoid, catatonic and chronic schizophrenia. It has a certain effect on depressive symptoms. Other uses include antivomiting.

Preparation[1]

The preparation of 2-methoxy-5-sulfamoylbenzoic acid (abbreviated as amide) is as follows:

Raw material ratio: 1Kg benzoyl, 1.7Kg 25% ammonia.

Amination reaction, the process is as follows:

1) Put the 25% ammonia solution into the ammoniation kettle.

II) Open the cooling water inlet and return valves, slowly add benzoyl under stirring, and control the temperature below 20°C. After adding, cover the feeding port to prevent ammonia gas from overflowing.

III) Close the inlet and return cooling water valves, slowly open the inlet and return steam valves, and keep the temperature in the kettle at 70-75°C for about 1.5 hours. After the reaction is completed, the ammonia is driven out by blowing, and the ammonia is recovered through the spray tower. Apply. After the ammonia drive is completed, close the steam inlet and return valves, and open the cooling water inlet and return valves to reduce the reaction temperature to 30±2°C.

IV) Turn on the vacuum pump, inhale hydrochloric acid, and then add hydrochloric acid to the reaction solution to adjust the pH to 1.0-1.5. Control the acid addition speed so that the temperature does not exceed 50°C. After the acid precipitation is completed, raise the temperature to 98±2°C and keep it warm for 15 minutes. Continue stirring to reduce the temperature of the reaction solution to normal temperature. Then stop stirring, close and return the cooling water valve, and let it stand for 2 hours (you can open it slightly, Return the cooling water valve and keep the standing temperature at 25~35℃).

V) After standing, centrifuge is started, the filter cake is washed with drinking water to pH 3-4, the filter cake is broken and placed in an oven, and dried at 83-87°C for 22 hours to obtain ammonia compound. The yield is 65-75%.

References

[1] CN201711193677.1 A method for reducing waste water and waste salt produced by the ammoniation reaction process during the production of methylsulfamate

微信扫一扫打赏

微信扫一扫打赏