Background and overview[1]

Poly(1,4-butene adipate) coating glue appeared on the market earlier and is widely used in the fabric coating industry at home and abroad. It can be used for sizing, printing and finishing. Use it Finished textiles have the advantages of crispness and beauty.

Preparation[1]

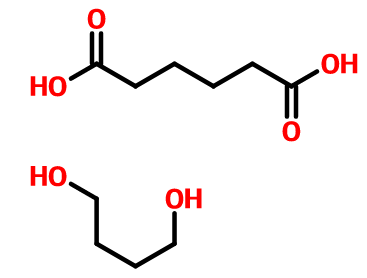

Polyester polyol B with a number average molecular weight of 1000, a hydroxyl value of 110 mgKOH/g and a functionality of 2.0 was prepared through polycondensation reaction using 1,4-butanediol and adipic acid at a molar ratio of 110:100. , put the polyetherester polyol and polyester polyol B based on the formula amount into the reaction kettle at room temperature, stir and raise the temperature to 100°C, dehydrate and degas under vacuum conditions for 2 hours, then cool to 50°C, and add 10 ppm benzene The acid chloride and pure MDI in the formula ratio can be obtained by reacting at 80°C for 2 hours.

Apply[2]

Poly(1,4-butene adipate) can be used to prepare rain-proof and stain-proof clothing. The rain-proof and stain-proof clothing includes a clothing body and a coating coated on the surface of the clothing body. The coating The layer is made of poly(1,4-butylene adipate) and nitrile rubber.

Coating ratio:

Poly(1,4-butene adipate) 10 parts by weight

Nitrile rubber 90 parts by weight

The preparation method of the coating is:

Dissolve poly(1,4-butene adipate) in toluene to obtain solution A. Dissolve nitrile rubber and vulcanizing agent in toluene to obtain solution B. At 15°C, dissolve the two solutions A and B. Mix and stir for 1 hour at a stirring speed of 1000r/min.

References

[1] [Chinese invention] CN202011633734.5 Polyurethane composite material for complex sole molds and preparation method thereof

[2] [Chinese invention] CN201110214767.0 Rainproof and anti-fouling clothing

微信扫一扫打赏

微信扫一扫打赏