Background and overview[1][2]

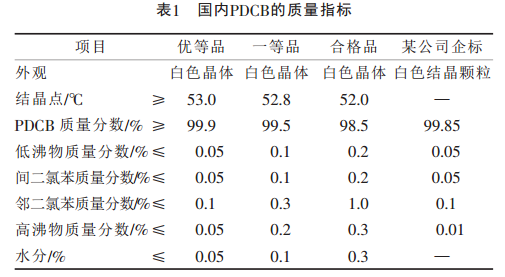

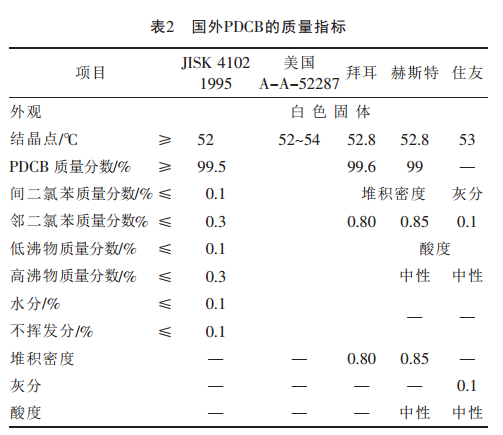

P-Dichlorobenzene, also known as 1,4-dichlorobenzene (hereinafter referred to as “PDCB”), is a white crystal with a molecular weight of 147.00, a melting point of 53.1°C, a boiling point of 174°C, a relative density of 1.2475 (20/4°C), and a refractive index. 1.5285, flash point 65℃, easily soluble in ethanol, soluble in ether and benzene, insoluble in water, sublimates at room temperature, and has a pungent camphor smell. Purified p-dichlorobenzene (purity above 99%) can be used as a moth-proofing agent, antifungal agent, dye, and medicine; it can also be used as a solvent; it can replace the potential carcinogen naphthalene for moth-proofing, and the effect is better. Industrially, it is mainly recovered from by-products of chlorobenzene production, and higher yields can be obtained through directional chlorination of benzene. At present, there are no unified national standards and industry standards for PDCB. Domestic enterprise standards are mostly formulated with reference to the corresponding standards of Western developed countries, but some indicators are not restricted. The quality indicators of PDCB at home and abroad are shown in Table 1 and Table 2.

Apply[2]

1 Used for hygiene, insect repellent, mildew proofing and deodorant

The main use of PDCB is to manufacture anti-moth and anti-fungal agents. Since the traditionally used naphthalene sanitary balls are potential carcinogens, foreign countries have banned the use of naphthalene in sanitary balls since the 1980s. In the 1990s, China began to ban naphthalene in the manufacture of sanitary balls, and PDCB became the most important anti-moth and mildew product. As an insecticide, moth-proof and mildew-proof agent, PDCB not only has strong insecticidal power and good effect, but also kills insects quickly and has a long-lasting fragrance. It can not only be used to prevent moth and deodorize woolen fabrics and books and materials, but also prevent and control black-skinned silverfish. , cockroaches and other pests and various molds such as Aspergillus and Penicillium, its performance is better than naphtha and camphor.

The consumption of PDCB in the United States, Japan and Western Europe accounts for 45%, 81% and 47% of the total consumption respectively, and China’s consumption in this area accounts for about 20% of the total consumption. PDCB has a strong adsorption and transformation effect on ammonia and amines, which can achieve the purpose of removing odors, disinfecting and killing insects, and purifying the air. Therefore, it can be used as a disinfectant and deodorant and is widely used in car parking lots, movie theaters, toilets, and waiting halls. It can be used for disinfection, deodorization and air purification in public places such as bathrooms and bathrooms. It can also be directly used for disinfection and deodorization of bathrooms and toilets. Different auxiliary materials, such as pigments, flavors, pesticides, moisture-proof agents, solvents, etc., can also be added to PDCB according to different locations and uses for mothproofing, mildew proofing, sterilization, and disinfection to obtain products with different properties that can meet different consumer needs.

2 Used in the production of polyphenylene sulfide

In terms of engineering plastics, PDCB is the main raw material for the production of polyphenylene sulfide (PPS), the sixth largest engineering plastic in the world. Because PPS has excellent heat resistance, flame retardancy, corrosion resistance, radiation resistance, creep resistance, fatigue resistance, non-toxicity, dimensional stability and good electrical properties, it is widely used in electronics, automobiles, home appliances, petrochemicals, It is an engineering plastic with broad application prospects in high-temperature adhesives, chemical machinery, aerospace, precision machinery and medical equipment, and its consumption is growing at an average annual rate of 20%. And every 1 t of PPS produced consumes about 1.5 t of PDCB, so, the development of PPS will bring a broad potential market to the production of PDCB.

3 Used in pesticide industry

In terms of pesticides, PDCB can be used to manufacture insecticides and fungicides, such as 2,5-chloroacetophenone, the intermediate for the preparation of organophosphorus insecticide fenitrocarb, and high-efficiency preparations such as sclerotin and sclerotin. The intermediate 3,5-dichloroaniline of the fungicide is used to prepare the agricultural fungicide 3,5-dichloro-2,3-dihydroxydiphenylmethane and the intermediate p-chlorophenol of the plant growth promoter PCPA, which is used to prepare the nitrogen fertilizer synergist agent, o-phenylenediamine, which is the intermediate for the pesticides chlorphenidazole and thiophanate, and 2,5-dichlorobenzoic acid, which is the intermediate for the herbicides dithiopin, bexicarb, etc.

4 Used in dye industry

In the dye industry, PDCB can be used as an intermediate and raw material for dyes, color bases, and pigments, such as for the production of 2,5-dichloronitrobenzene, the preparation of 2,5-dichloropyrazolinone and Its series of dyes include reactive bright yellow, acidic bright yellow, bright red agent, organic pigments, etc. Para-phenylenediamine produced from PDCB under the action of copper catalyst can be used to make sulfur dyes and azo dyes.

5 Used in the production of other industrial products

(1) It can be used as the beating part of fiber tissue in the papermaking industry.

(2) In the foundry industry, the molds made by mixing it with viscous resin have extensibility, minimal shrinkage, and no warping; ceramics made of PDCB for casting precision materials have smooth surfaces and precise volumes. .

(3) PDCB can be used as a binder for preparing refractory materials.

(4) Microporous polymeric plates made with PDCB as solvent have a matte surface, excellent elasticity and water permeability.

(5) In the preparation of chloroprene, adding PDCB can increase the yield to more than 67%. Under the action of copper catalyst, PDCB is used as raw material to produce p-phenylenediamine, which can also be used to synthesize aramid fibers and produce rubber antioxidants, gasoline inhibitors, and imaging agents.

(6) In addition, PDCB can also be used to produce special pressure lubricants and corrosion inhibitors.

Production[2]

At present, there are two main methods for preparing PDCB in industry, one is the co-production method, and the other is the directional catalytic chlorination method of benzene or chlorinated benzene.

Main reference materials

[1] Concise Dictionary of Fine Chemicals

[2]Cai Jianli, Long Jianyin, Yang Bin, Yan Yingchun. Production, technology and market prospects of p-dichlorobenzene [J]. China Chlor-Alkali, 2009(07):1-4.

微信扫一扫打赏

微信扫一扫打赏