Background and overview[1][2]

Potassium benzoate is white granules, flakes or crystalline powder. Odorless or slightly benzoin odor. Easily soluble in water and ethanol. Potassium benzoate can be used as an antiseptic and disinfectant. Mainly used in juice, carbonated drinks, margarine, margarine, and wine. According to FAO/WHO (1984) regulations, the use scope and use limit of potassium benzoate are based on sodium benzoate, and its use limit is converted into benzoic acid. Benzoic acid and its salts are widely used food preservatives at home and abroad. Its main products include benzoic acid, sodium benzoate, potassium benzoate, calcium benzoate, etc.

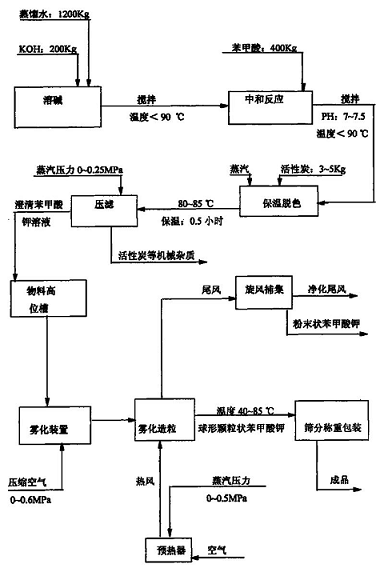

The manufacturing method of potassium benzoate products currently produced is: add distilled water to an enamel reaction tank with a stirrer, and then slowly add potassium hydroxide into it. After the potassium hydroxide is completely dissolved, slowly add benzoic acid , at this time, the enamel reaction tank continues to stir. Since the neutralization reaction of potassium hydroxide and benzoic acid is an exothermic reaction, when adding benzoic acid, control the speed of adding benzoic acid so that the reaction temperature does not exceed 90°C, and measure the PH of the reaction solution. value, when the pH value is less than 10, add acid intermittently, and control the pH value of the reaction solution at the end of the reaction to be 7 to 7.5.

After adding benzoic acid, add an appropriate amount of activated carbon, control the temperature in the tank to 80-85°C and keep it warm for half an hour, and then siphon it into a common decolorization tank; use common methods in the decolorization tank to continue to keep it under normal pressure and keep the temperature at 80 ~85℃ for half an hour; after the heat preservation is completed, use steam with a pressure of 0~0.25MPa to press the reaction liquid from the decolorization tank through the filter to a common high-level material tank. After separation by the filter, water-insoluble matter such as activated carbon is deposited on the filter on the filter paper; the solution entering the high-level tank is a colorless, clear and transparent potassium benzoate solution.

The colorless, clear and transparent potassium benzoate solution enters a common operating drum dryer from a high-level tank for drying. The drum steam pressure is 0~0.5MPa; the dried potassium benzoate is crushed and packaged to become the finished product. . The potassium benzoate product produced by this manufacturing method has a white powder appearance. This product has a lot of dust, poor fluidity and serious pollution when used. The production technology and equipment level of this product are backward.

Preparation[2]

A method for manufacturing potassium benzoate, which is characterized in that: the manufacturing method of potassium benzoate includes an atomization granulation process; the atomization granulation process includes filtering the colorless, clear and transparent potassium benzoate solution Carry out atomization, use powdered potassium benzoate as crystal nuclei in the granulation tower, and blow the crystal nuclei with hot air at a temperature of 40 to 85°C in the granulation tower, so that the crystal nuclei and the atomized benzene The potassium formate reaction liquid is in contact with each other for granulation. The process flow is as follows:

Because this method can produce granular potassium benzoate, when granular potassium benzoate is used, there is less dust and less pollution. The granular potassium benzoate has good fluidity, is suitable for mechanized and automated production requirements, and has good use effects.

Apply[3][4]

Potassium benzoate is used as a preservative and antimicrobial agent in the food industry; in addition, potassium benzoate is also used as a sounding agent for fireworks materials. Examples of its application are as follows:

1. Used as a preservative to prepare a sweetening composition, which contains a sweetener selected from the following: sucralose, acesulfame potassium, saccharin, aspartame, stevia extract, neotame , cyclamate, monk fruit extract, polyols, and mixtures thereof; preservatives; and acids. The compositions described above may also include a solvent selected from the group consisting of water, ethanol, glycerin, polyethylene glycol, polysorbate, and mixtures thereof. The solvent may comprise from about 70% to about 99.5% of the total weight of the composition.

2. Prepare a liquid compound fertilizer. It contains the following components in weight percentage: potassium sorbate 1.00%-3.00%; potassium benzoate 1.00%-3.00%; potassium phosphate 1.00%-3.00%; ammonium nitrate 5.00%-15.00%; phosphoric acid 1%-5 %; magnesium chloride 0.50%-2.00%; calcium chloride 0.50%-2.00%; microcrystalline cellulose 3.00%-8.00%; liquid paraffin 0.50%-1.00%; water 50.00%-85.00%; others are acid-base neutralizing solutions . The acid-base neutralizing solution is: 10% potassium hydroxide aqueous solution.

Considering the plant’s demand for nitrogen, phosphorus and potassium, and considering the solubility of the ingredients in water, choose soluble salt ingredients with a larger total amount of nitrogen, phosphorus and potassium, such as ammonium nitrate and potassium phosphate; taking into account the plant’s need for calcium, magnesium and phosphorus To meet the needs, choose soluble calcium salts and magnesium salts, such as magnesium chloride and calcium chloride, and use microcrystalline cellulose and paraffin oil to emulsify and isolate to prevent calcium salts and phosphates from forming insoluble salts; later use potassium hydroxide to Excessive phosphoric acid is neutralized to prevent the impact on soil pH; through the addition of preservatives potassium sorbate and potassium benzoate, in addition to supplementing normal potassium requirements, it can also inhibit the growth of soil microorganisms and indirectly prevent soil insects.

Main reference materials

[1] Chinese Baked Food Dictionary · Raw Materials and Food Additives Volume

[2] Chen Mingshen; Hu Xiaodong; Hao Qingyun. Manufacturing method of potassium benzoate. CN200410075779.X, application date 20041228

[3] Cao Yaohai; Ye Xiaojian; Zhang Hui. Sweetening composition. CN200880018486.4, application date 20080530

[4] Wu Juan. A kind of liquid compound fertilizer. CN201310141296.4, application date 20130423

微信扫一扫打赏

微信扫一扫打赏