Background and overview[1][2]

3-Methoxyphenyl acetone can be used to synthesize fragrances and tapentadol hydrochloride. Tapentadol hydrochloride, chemical name 3-[(1R,2R)-3-(dimethylamino)-1-ethyl-2-methylpropyl]phenol hydrochloride, is used It relieves moderate to severe acute pain in the central nervous system of adults and has good clinical efficacy. 3-Methoxypropiophenone is a key intermediate in the synthesis of tapentadol hydrochloride. If you inhale 3-methoxy phenyl acetone, please move the patient to fresh air; if skin contact occurs, take off contaminated clothing, rinse the skin thoroughly with soap and water, and seek medical treatment if you feel uncomfortable; if contact with eyes, separate eyelids, Rinse with running water or normal saline and seek medical attention immediately. If ingested, rinse mouth immediately. Do not induce vomiting and seek medical attention immediately.

At present, the traditional process for the industrial production of 3-methoxypropiophenone at home and abroad uses the reaction of 3-hydroxypropiophenone and dimethyl sulfate to obtain 3-methoxypropiophenone. The cost is high, the by-products are many, and the yield is low. Low, dimethyl sulfate is highly toxic and difficult to industrialize. Therefore, it is imperative to seek advanced technology and low production cost, and develop a green production process for 3-methoxypropiophenone.

Preparation[1][2]

Method 1: A green synthesis method of 3-methoxypropiophenone. In order to solve the above technical problems, the present invention adopts the following technical solution: add magnesium powder and anhydrous aluminum trichloride to a reactor equipped with a reflux condenser and a dropping funnel, and slowly add m-methoxy bromide from the dropping funnel. Benzene and tetrahydrofuran (THF) mixed solution, control the temperature of the reaction solution 30-80℃ to keep the solution in a slightly boiling state. After the dropwise addition is completed, heat and reflux for 0.5-1.0h to ensure that the magnesium reaction is complete, and obtain Grignard reagent. While stirring, slowly add propionitrile dropwise to the Grignard reagent. After the dropwise addition is completed, react for 1.0-2.0h. After the reaction is completed, slowly add 3 mol/L hydrochloric acid dropwise in a cold water bath to decompose the addition product and separate the inorganic phase. The organic phase is distilled under normal pressure to remove THF, and distilled under reduced pressure to obtain 3-methoxypropiophenone.

Method 2: Preparation process of 3-methoxypropiophenone, which is characterized in that the preparation process includes the following steps:

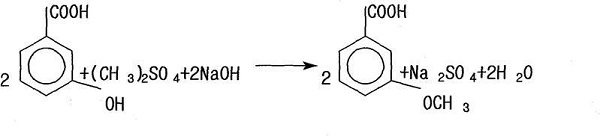

1) Preparation of 3-methoxybenzoic acid: Add water, solid NaOH, m-hydroxybenzoic acid and dimethyl sulfate to the container for etherification reaction, then add acidic solution for acidification treatment, centrifuge and After drying treatment, 3-methoxybenzoic acid is obtained;

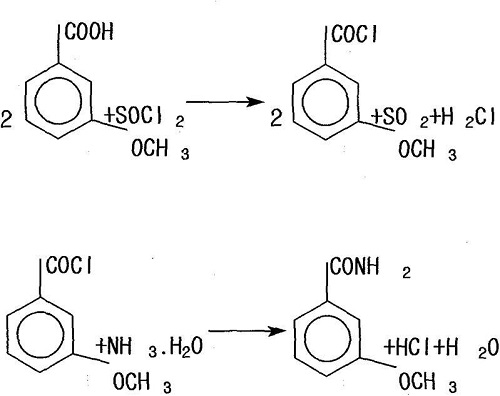

2) Preparation of 3-methoxybenzoyl chloride and m-methoxybenzamide: Add the above-mentioned m-methoxybenzoic acid and toluene into the container, mix the two evenly, and then add chlorine Carry out acyl chlorination reaction with sulfoxide to obtain a mixed solution containing m-methoxybenzoyl chloride; add ammonia water and ice cubes in another container, and then put the above mixed solution containing m-methoxybenzoyl chloride into ice for hydrolysis , m-methoxybenzamide is obtained after centrifugation, water washing, draining and drying;

3) Preparation of m-methoxybenzonitrile: Add m-methoxybenzamide, acetonitrile and phosphorus oxychloride in a container to form a mixed solution containing m-methoxybenzamide; in another container Add ice water to the mixture, and then put the above mixture containing m-methoxybenzamide into the solution for hydrolysis, and obtain m-methoxybenzonitrile after layered washing and distillation;

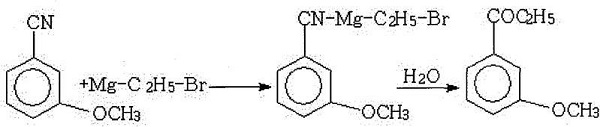

4) Preparation of 3-methoxypropiophenone: Add magnesium chips, tetrahydrofuran, toluene and ethyl bromide to the container, and then add m-methoxybenzonitrile to obtain m-methoxybenzonitrile. Mixed liquid; acidify the above mixed liquid containing m-methoxybenzonitrile in another container, and then obtain 3-methoxypropiophenone finished product through layering, extraction, water washing and distillation.

Apply[2][3]

3-Methoxypropiophenone is a key intermediate used in the production of the drug tapentadol. Tapentadol is a novel oral analgesic drug that acts on the central nervous system. It has two mechanisms of action: one is acting on the opioid μ2 receptor, inhibiting pain in the spinal cord by improving pain sensation and emotional factors. transmission, thereby affecting and controlling the activity of the cerebral cortex part that senses pain; the other is the inhibition of norepinephrine reuptake, inhibiting its reabsorption into nerve cells, thereby increasing the level of norepinephrine in the brain, similarly Also acts as an analgesic.

Tapentadol does not rely on metabolic activation and has no metabolic activation products. It has a strong effect on various acute inflammations and neuralgias. Its efficacy is between morphine and tramadol. It can be injected intravenously or orally. Obtaining higher blood concentrations, it is less likely to produce analgesic tolerance and dependence than morphine. Pharmacokinetic studies show that the oral absolute bioavailability of tapentadol is 32%, and its metabolism is stable. It can be almost completely metabolized into inactive conjugates, and its metabolism reaches equilibrium after about 5 days.

Main reference materials

[1] Li Dejiang; Zhou Yang; Wang Long; Zhang Nuonuo; Zheng Kaibo; Li Xiurong. A synthesis method of 3-methoxypropiophenone. CN201610924744.1, application date 20161024

[2] Tang Baoqing; Qin Guohong; Fu Zhiming; Ju Ming. Preparation process of m-methoxypropiophenone. CN200910035465.X, application date 20090928

微信扫一扫打赏

微信扫一扫打赏