Background[1][2]

P-Toluidine is also known as p-aminotoluene. White shiny flake or leaf crystal. Easily soluble in alcohol, ether, acetone, methanol, carbon disulfide, oil and dilute acid, slightly soluble in water. Can evaporate with water vapor. In the prior art, the process of reducing p-nitrotoluene to produce p-toluidine uses iron powder reduction and liquid-phase catalytic hydrogenation reduction. These two processes are relatively mature.

The iron powder reduction method will produce a large amount of amine-containing iron sludge during the production process, which cannot be processed; the liquid phase catalytic hydrogenation reduction method has two types: solvent method and solvent-free method. The solvent method uses methanol as the solvent and adds all the The required catalyst is that hydrogen reacts with p-nitrotoluene under a certain temperature and pressure. After the reaction is completed, the mixed liquid is filtered, left standing or dynamically separated to remove the catalyst, and the solvent is recycled and recycled. The crude p-toluidine can be separated To obtain the finished product, this method reduces the production capacity per unit volume of the equipment due to the presence of organic solvents. At the same time, recycling the solvent also brings problems such as high cost and environmental pollution.

Solvent-free liquid-phase catalytic hydrogenation is to add p-nitrotoluene and catalyst into the reactor in a certain proportion, control a certain temperature and pressure, and react hydrogen with p-nitrotoluene. After the reaction is completed, pass Let it stand to separate the crude p-toluidine from the catalyst, and then dehydrate and distill the crude p-toluidine to obtain the finished product; the solvent-free liquid-phase catalytic hydrogenation process to produce p-toluidine is better than the solvent-based liquid-phase catalytic hydrogenation production process. The p-toluidine process subtracts the solvent recovery process, saving investment, and the process flow is simple. However, the process also has some defects: the process is an intermittent operation and is highly labor-intensive. Although the DCS distributed control system has been introduced into the device in recent years, However, the operation is still relatively cumbersome; the operating pressure is high, which brings certain hidden dangers to production safety; the Raney nickel catalyst used in this process is expensive, flammable, and difficult to recycle; the process is intermittent operation, which limits the further increase in output. .

As can be seen from the above, in the existing technology, there is a large amount of unprocessable amine-containing iron sludge caused by the reduction of iron powder to produce p-toluidine; the solvent method liquid phase hydrogenation reduction brings huge equipment and easy solvent recovery for workers. Health hazards; solvent-free liquid-phase hydrogenation reduction brings cumbersome operations, expensive catalysts, easy spontaneous combustion, difficulty in recycling, high operating pressure, and potential safety hazards.

Apply[3][2]

P-Toluidine is the dye red base GL, methylamine red lake, basic fuchsin, methyl peri-acid and 4-aminotoluene-3-sulfonic acid, triphenylmethane dye and oxazine dye, drug B Intermediates for aminopyrimidines, pesticides such as fenacetate and other products. Examples of its application are as follows:

1. Preparation of 1-hydroxy-4-(p-toluidino)-anthraquinone.

1-Hydroxy-4-(p-toluidino)-anthraquinone, Chinese alias boron reagent, transparent violet B, oil-soluble violet 13, oil-soluble violet B; used as a enzyme reagent for the determination of boron, mainly used The puree coloring of polyester fiber can also be used to prepare masterbatch for polyester. Preparation steps include:

1) Preparation of condensation catalyst: swell 100 parts of thiourea resin in 500-1000 parts of boric acid by weight, soak for 1-5 hours, filter, wash with deionized water until PH=7, add 1-10 parts of 2-Hydroxy-5-sulfobenzoic acid, 0.01-0.1 parts of neodymium acetate; 0.01-0.1 parts of 5,6-diamino-1,10-phenanthroline, 1-5 parts of 2-fluoroisonic acid Acid, stir and react at 20-50°C for 5-10 hours. After the reaction is completed, filter and dry to obtain the condensation catalyst;

2) Preparation of 1-hydroxy-4-p-toluidinoanthraquinone: According to parts by weight, mix 100 parts of 1,4-dihydroxyanthraquinone, 80-150 parts of p-toluidine, and 300-800 parts of ethers Solvent, 30-100 parts of condensation catalyst are put into the reactor, and the system gradually heats up to react. After the reaction, the product is filtered, the filter cake is washed, dried, and then refined to obtain 1-hydroxy-4-p-toluidine. Anthraquinone finished product.

2. Preparation of p-cresol.

The method includes the steps: 1) Hydrolyze p-toluidine under a catalyst and acidic conditions to obtain a hydrolyzed mixed solution; 2) Let the hydrolyzed mixed solution obtained in step 1) stand and separate into layers, and the organic phase After extraction and separation, crude p-cresol solution and by-product 4,4′-dimethyldiphenylamine solution are obtained.

The system includes a hydrolysis reactor, a filter connected in series with the hydrolysis reactor, a layered filter connected in series with the filter, an extraction tower connected in series with the layered filter, and a first rectification tower and a second distillation tower connected in series with the extraction tower. A rectification tower, the first rectification tower is connected to a first vacuum dryer, and the second rectification tower is connected to a second vacuum dryer. Through the method and system provided by the invention, high-purity p-cresol can be prepared, and crude 4,4′-dimethyldiphenylamine can be co-produced.

Preparation[4]

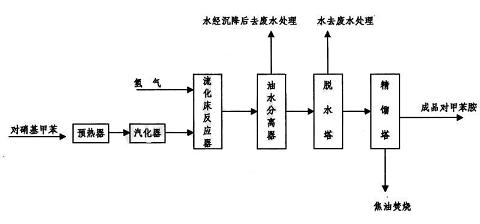

A process for producing p-toluidine by gas phase catalytic hydrogenation, which includes raw material vaporization, reduction and static stratification processes. It is characterized in that the raw material p-nitrotoluene is preheated and vaporized and then continuously enters the fluidized bed. In the hydrogen In the presence of a catalyst, p-toluidine is produced by gas phase catalytic reduction. The specific process is:

First, slowly introduce nitrogen into the fluidized bed through the pipeline to replace the air in the fluidized bed. The oxygen content to be tested is 95%, turn on the electric heater to raise the temperature, slowly increase the bed temperature to 100℃~150℃, control the sudden rise in temperature by adjusting the air volume, and wait until there is no sudden rise in temperature.�Restore the original air volume, raise the temperature slowly and evenly to 200℃~280℃, and keep it warm for 4 hours. After the insulation is completed, turn off the electric heater to reduce the outlet temperature of the electric heater to 200℃~250℃, and control the top temperature of the fluidized bed at Above 150℃, the pressure in the fluidized bed is ≤0.2Mpa.

Then, turn on the preheater steam to preheat p-nitrotoluene, start the p-nitrotoluene feed pump, initially feed 50kg/h, and gradually increase the feed amount to normal within 2 hours. The normal feed amount is less than 800-1200kg/h. ; Furthermore, use water to control the fluidized bed reaction center temperature at 210°C ~ 290°C, and the generated p-toluidine gas is condensed into p-toluidine liquid through the condenser and enters the oil-water separator to naturally stratify to obtain crude product p-toluidine; finally, the crude product p-toluidine is obtained. Toluidine is dehydrated and distilled to obtain the finished product.

Production wastewater treatment[5]

The wastewater from p-toluidine production contains benzene and aniline compounds. According to the characteristics of high toxicity and high concentration of aniline in p-toluidine wastewater, if it is directly discharged without wastewater treatment, it will not meet the national secondary discharge standards. Does not meet national environmental protection requirements. In p-toluidine wastewater, formaldehyde and aluminum sulfate are added to perform a polycondensation reaction and the condensate is precipitated, and then the polymer flocculant polyacrylamide is added to precipitate. As a result, the content of aniline compounds in wastewater dropped significantly. Then it is treated with the iron-carbon method. The effluent from the iron-carbon reaction tower is mixed with other industrial wastewater for aerobic and biochemical treatment, and reaches the national secondary emission standard. Specific process steps include:

Step 1. Polycondensation reaction: Use sulfuric acid to adjust the pH value to 5.5~6.5, control the temperature of the wastewater above 80°C, add formaldehyde and aluminum sulfate to the wastewater, stir to cause the polycondensation reaction of aniline compounds and formaldehyde, and reflux reaction 30~120 minutes. Adding aluminum sulfate can solve the problem of the polymer produced adhering to the walls of the reactor and the stirrer.

Step 2, flocculation and precipitation: Add polymer flocculant polyacrylamide to the wastewater after the polycondensation reaction for precipitation and separation.

Step 3. Iron-carbon treatment: The supernatant after flocculation and precipitation is adjusted to a pH value of 2-3 with sulfuric acid and then enters the iron-carbon reaction tower. The packing in the tower consists of iron shavings and granular activated carbon. The weight ratio of iron shavings to granular activated carbon is 4-6:1, and the wastewater stays in the iron-carbon reaction tower for 4-12 hours.

Step 4. Neutralization and coagulation reaction: Add alkali solution to the effluent of the iron-carbon reaction tower to adjust pH=8.5~9, and add polymer flocculant polyacrylamide (PAM) to promote flocculation and precipitation, so that toxic substances and other organic matter further removed.

Step 5. Biochemical treatment: The above-mentioned wastewater after removal of biochemical inhibitors is mixed with other industrial wastewater, and through aerobic biological treatment, the organic matter is greatly degraded. The hydraulic retention time is 24 to 40. After the mud water is separated in the secondary sedimentation tank, the chemical oxygen demand (COD) of the effluent is less than 150mg/L, which meets the national secondary emission standards.

Main reference materials

[1] Compound Dictionary

[2] CN201710745426.3 A preparation method of 1-hydroxy-4-p-toluidinoanthraquinone

[3] CN201610325894.0 A method and production system for preparing p-cresol by catalytically hydrolyzing p-toluidine

[4] CN200610038385.6 Process for producing p-toluidine by gas phase catalytic hydrogenation

[5] CN200610038929.9 Treatment process of p-toluidine wastewater

微信扫一扫打赏

微信扫一扫打赏