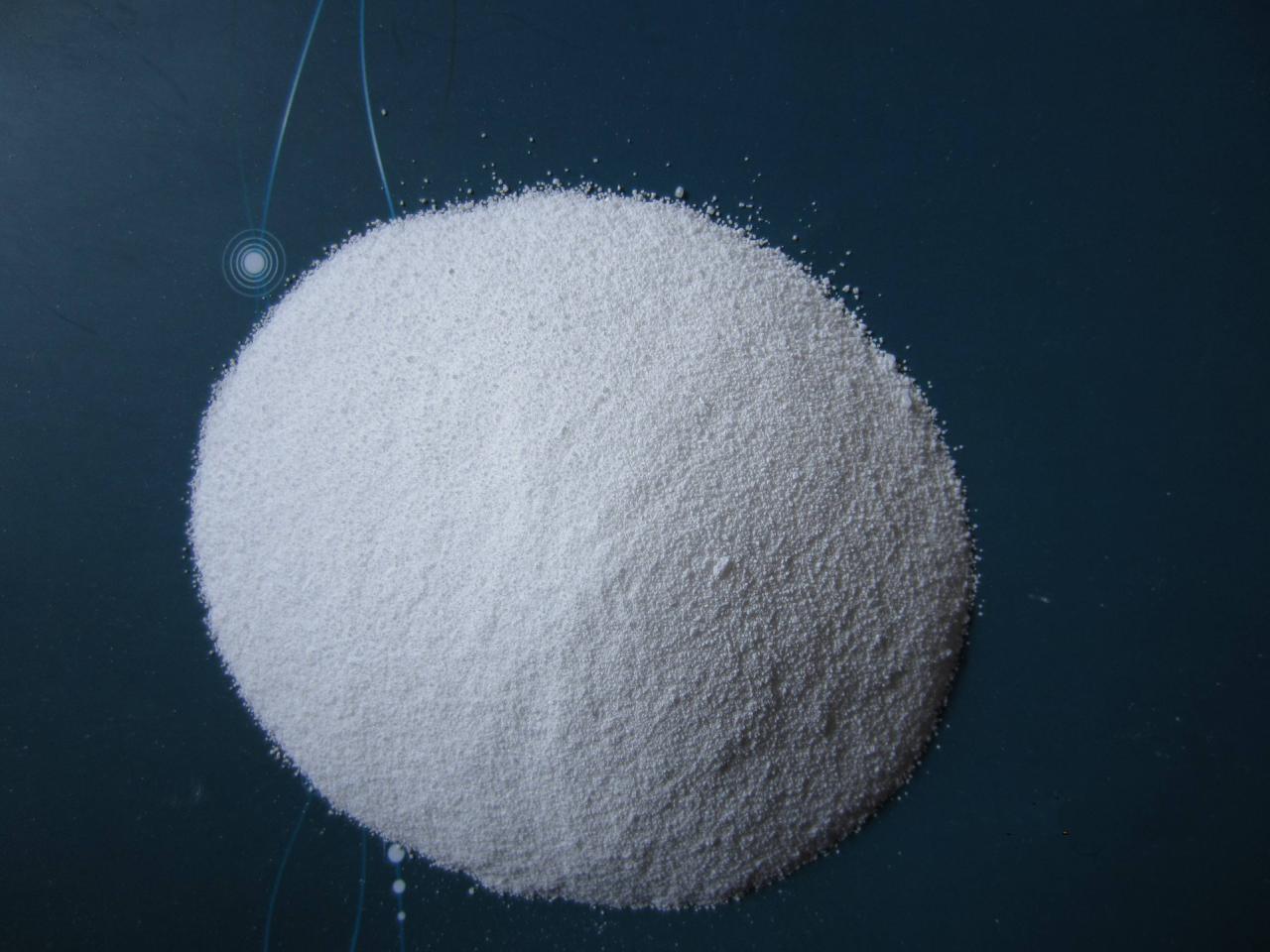

Secondary Alkane Sulfonate (SAS)

Anionic surfactantsSecondary alkanesulfonates are relatively new productsSurfactants . It is produced by reacting sulfur dioxide and air with C12~C14 n-alkanes.

This reaction is obviously different from sulfonation and esterification with sulfuric acid, and is called oxysulfonation. The overall balanced formula of the reaction is as follows:

R CH2R+2SO2+O2-H2O— K-CH-R-H2SO4

SO2H

During the reaction process, the sulfonic acid group can appear at any position on the linear alkane group. After oxysulfonation, it is similar to the production of LAS and is directly dried and dried.

SAS has similar foaming and washing properties to LAS, and has good water solubility. SAS is currently only produced in Western Europe, and its main purpose is to compound it into liquid washing agents, such as liquid household dishwashing detergents. This process was first developed by the West German company Hester, with the brand name HasiapmSAS6. Xuan products contain 60% active ingredients. The disadvantage of SAS is that the laundry detergent using it as the main component is sticky and not loose. Therefore, only used in liquid formulations.

Alpha-olefin sulfonate (AOS)

α-olefins are produced by cracking paraffin oil or oligomerizing Zilleg ethylene. The C12~C18 α-olefins obtained after coarse separation are diluted with air. It is produced by sulfonating sulfur trioxide and then neutralizing it. The reaction process is more complex, producing a mixture of multiple compounds. The first step initially produces about 40% of olefin sulfonic acid and 60% of 1.3- and 1,4-olefin sultones.

The sultone in the sulfonated product is further hydrolyzed by sodium hydroxide aqueous solution and neutralized at the same time. In the obtained product, the hydroxyalkane sulfonate and The ratio of olefin sulfonates (AOS) is approximately 2:1. In the hydrolyzed product, approximately 60% are olefin sulfonates and 40% are hydroxyalkane sulfonates.

In general, AOS and LAS have similar properties, but AOS is slightly less irritating to the skin and biochemically degrades slightly faster. Due to its simple production process, The cost of raw materials is low, and AOS has always had great appeal. In the past, there were certain difficulties in controlling the production process. In recent years, improvements in equipment have basically solved this problem. Since 1980, the production and application of AOS have been on the rise. The main use of AOS is in the preparation of liquid detergents and cosmetics.

微信扫一扫打赏

微信扫一扫打赏