Carbon nanotubes have excellent performance and shipments maintain steady growth

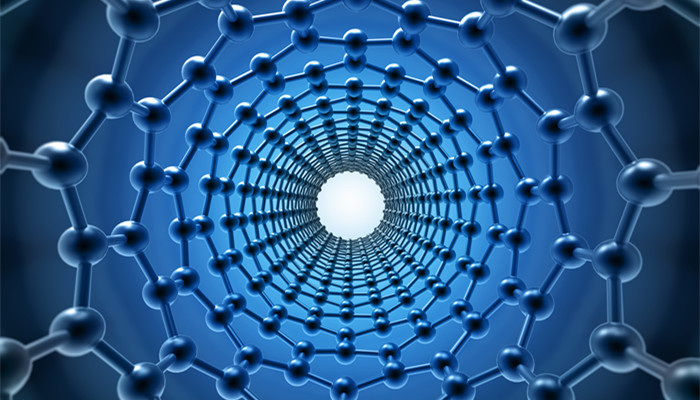

Carbon nanotube, also known as Bucky tube, is a one-dimensional quantum material with a special structure. Its radial size is on the order of nanometers, and its axial size is on the order of microns. Both ends of the tube are basically sealed. Carbon nanotubes can be divided into single-walled carbon nanotubes and multi-walled carbon nanotubes according to the number of tube walls; according to different structural characteristics, they can be divided into armchair-shaped nanotubes, zigzag-shaped nanotubes and spiral nanotubes.

The upstream of the carbon nanotube industry chain is the supply of raw materials such as liquid nitrogen, propylene, dispersants, and NMP; the midstream is the production of subdivided products; the downstream is widely used in 3C digital, semiconductors, energy storage power stations, new energy vehicles and other fields.

According to the “China Carbon Nanotube Industry Market In-depth Research and Development Prospects Forecast Report 2023-2028” released by the Industrial Research Center, Carbon nanotubes have excellent electrical conductivity, mechanical properties and chemical properties, and have been one of the research hotspots in the field of materials science for many years. In recent years, with the continuous advancement of my country’s construction of a technological power, the continuous enhancement of corporate R&D and innovation capabilities, and the continuous expansion of the scale of semiconductors, new energy vehicles and other industries, domestic carbon nanotube shipments have maintained a steady growth trend. my country’s carbon nanotube shipments in 2022 will be approximately 110,000 tons, a year-on-year increase of approximately 17%.

Carbon nanotubes can be prepared in various ways, including electrolysis, arc discharge, solar energy, laser evaporation, and catalytic pyrolysis lamps. Among them, the arc discharge method is the earliest method used to prepare carbon nanotubes. It has the advantages of easy availability of raw materials and high straight crystallinity of the product tube. However, due to the disadvantages such as difficulty in controlling the discharge process and low yield, it is currently mainly used for single-wall carbon nanotubes. of production. Catalytic pyrolysis, also known as chemical vapor deposition, has the advantages of easy parameter control, high product purity, and high yield. It is currently a widely used preparation method.

The lithium battery field is the most important application field of carbon nanotubes. In recent years, driven by national policy support and market demand, my country’s new energy vehicle production and sales have maintained a rapid growth trend, promoting the continuous expansion of the lithium battery market and providing a broad consumer market for carbon nanotubes. In 2022, my country’s new energy vehicle production will exceed 7 million vehicles, a year-on-year increase of approximately 97%, and sales will be approximately 6.9 million vehicles, a year-on-year increase of approximately 93%.

Industry analysts People said that the research and development and production of carbon nanotubes have high requirements on equipment and technology, and the industry has strong barriers to entry. At present, the number of domestic carbon nanotube manufacturers is small, leading companies occupy most of the market share, and the industry concentration is high. Jiangsu Tiannai Technology Co., Ltd. is a high-tech enterprise dedicated to the research and development, production, application development and sales of carbon nanotubes and graphene. The company’s products include carbon nanotube powder, carbon nanotube conductive slurry, carbon nanotube Conductive masterbatch, etc. account for more than 40% of the domestic carbon nanotube market share and are a representative enterprise in the industry.

微信扫一扫打赏

微信扫一扫打赏