my country’s solid electrolyte membrane (SOLID) production process needs to be improved and there are few market participants

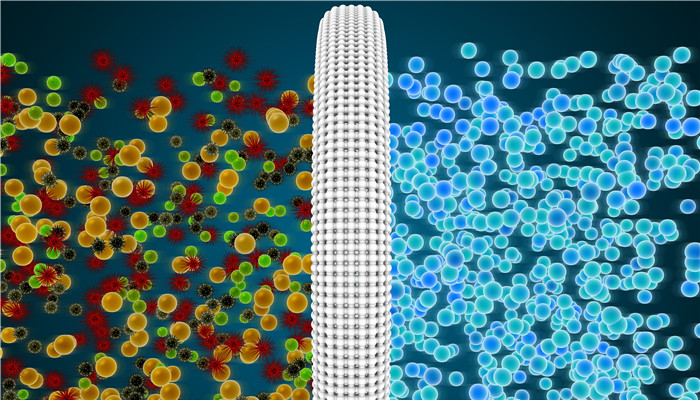

Solid electrolyte membrane (SOLID), also known as solid electrolyte membrane, refers to a proton exchange membrane made of proton conductive materials. Compared with traditional liquid electrolytes, solid electrolyte membranes have the advantages of good electrochemical stability, good safety, high energy density, and good high-temperature stability, and have broad application prospects in the field of solid-state batteries.

The upstream of the solid electrolyte membrane industry chain supplies raw materials, including ceramics, polymers, glass, etc. Perovskite material is the core raw material of solid electrolyte membrane. It is a ceramic oxide with the same crystal structure as calcium titanate. It has the advantages of simple production process and good photoelectric properties. It is widely used in photovoltaics, optoelectronic devices and other fields. my country has a vast territory and rich mineral resources, with various types of perovskites and high output. At present, my country has become the world’s largest producer of perovskite materials, accounting for nearly 60% of the world’s output. Adequate supply of raw materials will lay a good foundation for the development of the solid electrolyte membrane industry.

The midstream of the solid electrolyte membrane industry chain is product manufacturing, and dry process and wet process are the main film-forming processes. Dry process, also known as dry pressing process, refers to pressing solid electrolyte into sheet materials. This method has the advantages of high production efficiency, green environmental protection, and low production cost, but the thickness of the film made by this method is larger; wet process Including three types: skeleton support film formation, mold support film formation and positive electrode support film formation. This method has the disadvantages of complex production process and high production cost. At present, my country’s solid electrolyte membrane has not yet achieved mass production, and its production process still needs to be improved.

According to the “2023-2028 China Solid State Electrolyte Membrane (SOLID) Industry Market In-depth Research and Development Prospects Forecast Report released by the Industrial Research Center 》 shows that the downstream of the solid electrolyte membrane industry chain is the application field, solid-state batteries are its end products, and consumer electronics, electric vehicles, etc. are its main application fields. Benefiting from national policy support and technological progress, the update and iteration speed of my country’s consumer electronics products and electric vehicles continues to accelerate, and the industry’s prosperity continues to increase. In the future, as application demand becomes increasingly strong, the development space of my country’s solid electrolyte membrane industry will further expand.

but the solid electrolyte membrane industry in my country started late compared with overseas developed countries. There are fewer companies with R & D and production capabilities, and demand is highly dependent on imports. At present, the main manufacturers of solid electrolyte membranes in my country include Xingyuan Materials, Shandong Zhanggu, Hancheng Technology, Kerun New Materials, etc.

Industry analysts said that as an important component of solid-state lithium batteries, solid-state electrolyte membranes have strong market demand and good industry development prospects. In recent years, due to factors such as high technical barriers and high production costs, overseas companies have dominated my country’s solid electrolyte membrane market. It is expected that in the coming period, as local companies continue to exert their efforts, the localization process of my country’s solid electrolyte membrane market is expected to accelerate.

微信扫一扫打赏

微信扫一扫打赏